Home > Press > Paving the way for real-world nanotechnology products

|

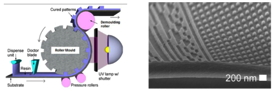

| 200nm - Roll-to-roll nanoimprinting allows for the creation of patterned surfaces on flexible substrates such as plastic web materials over large areas. In particular it is targeted for high throughput (meters per minute), room temperature processing with achievable feature size resolutions as small as 50 nm and below. |

Abstract:

A*STAR's new Nanoimprint Foundry will bridge the gap between laboratory-based nanotechnologies and real-world products. This is the first time that Singapore nanotechnology suppliers and manufacturers have been brought together to speed up productisation of nanoimprinting, a technology that imbues ordinary surfaces with unique properties for applications in sectors like consumer care, biomedical devices, optics, filtration, displays and maritime.

Paving the way for real-world nanotechnology products

Singapore | Posted on September 29th, 2013A*STAR's new Nanoimprint Foundry will bridge the gap between laboratory-based nanotechnologies and real-world products. This is the first time that Singapore nanotechnology suppliers and manufacturers have been brought together to speed up productisation of nanoimprinting, a technology that imbues ordinary surfaces with unique properties for applications in sectors like consumer care, biomedical devices, optics, filtration, displays and maritime.

Adhesives that leave no sticky residue, ‘skins' that keep medical instruments germ-free, new anti-reflective protectors for displays or surfaces that prevent barnacles from attaching to ships.These are just some of the products that nanoimprinting technology is capable of producing. A*STAR's Institute of Materials Research and Engineering (IMRE) and its partners launched a new Nanoimprint Foundry that will develop, test-bed and prototype specially engineered plastics and surfaces for the specific purpose of commercialising the technologies. Possible applications of nanoimprint technology include dry adhesives, aesthetic packaging, contact lenses, biomedical cell scaffolds, anti-frost surfaces and anti-bacteria materials.

The multi-party investment will bring together national research organisations, suppliers and manufacturers spanning the nanotechnology value chain, and government agencies to promote the technology. The Foundry is part of a masterplan spearheaded by A*STAR to push translational research and accelerate commercialisation of home-grown technologies. In partnership with other A*STAR research institutes, IMRE will work with companies like Toshiba Machines Co Ltd, EV Group, NTT Advanced Technology Corporation, NIL Technology ApS, Kyodo International Inc., micro resist technology GmbH, Nanoveu Pte Ltd and Solves Innovative Technology Pte Ltd to produce prototypes for real-world products and applications. The Foundry and its partners will also work closely with Singapore's Economic Development Board (EDB) and SPRING to promote its nanoimprint applications to industry as part of the plans to build up Singapore's high-value manufacturing capabilities.

"We can help companies develop up to 20,000 samples for proof-of-concept and pilot production allowing manufacturers to shorten the product cycle but minus the heavy capital R&D investment", said Dr Karen Chong, the IMRE scientist who is heading the Foundry. Dr Chong added that the Foundry will be a one-stop shop for companies seeking to conceive, design and develop solutions for new, revolutionary products based on the versatile nanoimprint technology.

"The Foundry gives us the tools for creating real products that target industry end users and ultimately consumers", explained Mr Masayuki Yagi, Director & General Manager, Advanced Machinery Business Unit, Toshiba Machines Co Ltd, Japan on why the company chose to participate in the initiative. "Toshiba Machines and the Foundry will aim to deliver innovative engineering solutions based on nanoimprint and be the best partner for leading industries".

According to Mr Koh Teng Kwee, Director of Solves Innovative Technology Pte Ltd, "Working with IMRE since ICON 1[1], I am sure IMRE's nanoimprint technology and know-how is now ready for industrial adoption. In my opinion, IMRE is able to provide everything needed for a new product realisation involving nanoimprinting."

"There is a billion-dollar, virtually untapped market for new advanced nanotechnology products that can make use of what the Foundry has to offer", said Prof Andy Hor, Executive Director for IMRE, adding that the initiative will hasten the industrialisation of nanoimprinting in this lucrative market segment. In consumer care for example, the global market for contact lenses - where nanoimprint technology can be used to produce new functionalities like multi-coloured lenses - is expected to grow to USD 11.7 billion by 2015[2].

"The Foundry is the first one-stop shop to pull different value chain partners together to offer solutions based on nanoimprint through equipment, moulds, materials and applications to end user companies", said Dr Tan Geok Leng, Executive Director of A*STAR's Science and Engineering Research Council which oversees a number of the research institutes dedicated to the physical sciences and engineering. "The new Foundry is part of Singapore's strategy to create a new, advanced high-value manufacturing sector to support its growing knowledge-based economy."

"As part of EDB's vision to position Singapore as an Advanced Manufacturing Hub, we will continue to work with companies to co-create and adopt advanced manufacturing technologies. We see this new Research Foundry as one of the key infrastructures to strengthen nanoscale-manufacturing capabilities in Singapore", said Mr Yi-Hsen Gian, Director (i3), Economic Development Board (EDB), Singapore.

The Foundry was launched on 30 September 2013 during a ceremony that also saw collaboration agreements signed between A*STAR and its industry partners.

####

About Agency for Science, Technology and Research (A*STAR)

The Agency for Science, Technology and Research (A*STAR) is Singapore's lead public sector agency that fosters world-class scientific research and talent to drive economic growth and transform Singapore into a vibrant knowledge-based and innovation driven economy.

In line with its mission-oriented mandate, A*STAR spearheads research and development in fields that are essential to growing Singapore’s manufacturing sector and catalysing new growth industries. A*STAR supports these economic clusters by providing intellectual, human and industrial capital to its partners in industry.

A*STAR oversees 20 biomedical sciences and physical sciences and engineering research entities, located in Biopolis and Fusionopolis as well as their vicinity. These two R&D hubs house a bustling and diverse community of local and international research scientists and engineers from A*STAR’s research entities as well as a growing number of corporate laboratories. Please visit www.a-star.edu.sg.

About the Institute of Materials Research and Engineering (IMRE)

The Institute of Materials Research and Engineering (IMRE) is a research institute of the Agency for Science, Technology and Research (A*STAR). The Institute has capabilities in materials analysis & characterisation, design & growth, patterning & fabrication, and synthesis & integration. We house a range of state-of-the-art equipment for materials research including development, processing and characterisation. IMRE conducts a wide range of research, which includes novel materials for sensors & Transducers, consumer care, organic solar cells, photovoltaics, printed electronics, catalysis, bio-mimetics, microfluidics, quantum dots, heterostructures, sustainable materials, atom technology, etc. We collaborate actively with other research institutes, universities, public bodies, and a wide spectrum of industrial companies, both globally and locally. For more information about IMRE, please visit www.imre.a-star.edu.sg.

A*STAR’s Nanoimprint Foundry

A*STAR’s Nanoimprint Foundry is an R&D based nanoimprint foundry dedicated to driving the applications and industrial adoption of nanoimprint as a transformative technology across multiple industry sectors. The Foundry is a co-development between Science and Engineering Research Council (SERC), Institute of Materials Research and Engineering (IMRE) and also Exploit Technologies Pte Ltd (ETPL) of the Agency for Science Technology and Research (A*STAR), with the participation of other multi-disciplinary A*STAR institutes and industry collaborators to enable the evolution of nanoimprint technology from the laboratory to the manufacturing floor.

For more information, please click here

Contacts:

Mr Eugene Low

Tel 65 6874 8491

Copyright © Agency for Science, Technology and Research (A*STAR)

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Display technology/LEDs/SS Lighting/OLEDs

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() Efficient and stable hybrid perovskite-organic light-emitting diodes with external quantum efficiency exceeding 40 per cent July 5th, 2024

Efficient and stable hybrid perovskite-organic light-emitting diodes with external quantum efficiency exceeding 40 per cent July 5th, 2024

Marine/Watercraft

Products

![]() Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

![]() Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

![]() Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

![]() Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Nanomedicine

![]() New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Water

![]() Taking salt out of the water equation October 7th, 2022

Taking salt out of the water equation October 7th, 2022

Alliances/Trade associations/Partnerships/Distributorships

![]() Chicago Quantum Exchange welcomes six new partners highlighting quantum technology solutions, from Chicago and beyond September 23rd, 2022

Chicago Quantum Exchange welcomes six new partners highlighting quantum technology solutions, from Chicago and beyond September 23rd, 2022

![]() University of Illinois Chicago joins Brookhaven Lab's Quantum Center June 10th, 2022

University of Illinois Chicago joins Brookhaven Lab's Quantum Center June 10th, 2022

Printing/Lithography/Inkjet/Inks/Bio-printing/Dyes

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

![]() Disposable electronics on a simple sheet of paper October 7th, 2022

Disposable electronics on a simple sheet of paper October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||