Home > Press > Building 3D fractals on a nano scale

|

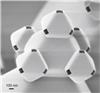

| Corners with nano pores |

Abstract:

It starts with one 3D structure with eight planes, an octahedron. This repeats itself to smaller octahedra: 625 after just four steps. At every corner of a new octahedron, a successive octahedron is formed. A truly fascinating 3D fractal ‘building' is formed on the micro and nano scale. It can be used for high performance filtering, for example. Scientists of the MESA+ Institute for Nanotechnology of the University of Twente in The Netherlands present these structures in the Journal of Micromechanics and Microengineering (JMM).

Building 3D fractals on a nano scale

Enschede, Netherlands | Posted on June 1st, 2013A fractal is a geometric structure that can repeat itself towards infinity. Zooming in on a fragment of it, the original structure becomes visible again. A major advantage of a 3D fractal is that the effective surface rises with every next step. Looking at the octahedra, after four steps the final structure is not much bigger than the original octahedron, but the effective surface has been multiplied by 6.5. The smallest octahedra are 300 nanometers in size, with on every corner a nano pore of 100 nanometer. Having 625 of these nano pores on a limited surface area, a very effective filer with low flow resistance is formed. The Dutch scientists also experiment with capturing living cells within these octahedral, to be able to study the interaction between the cells. Further interesting research is related to sending light through the octahedron structure: how will it interact?

Corner lithography

To be able to create the repeated 3D structure, the scientists developed a technique called ‘corner lithography''. At first, a pyramid form is etched in silicon. The next step is applying a layer of silicon nitride on the pyramid. After removing this subsequently, a tiny bit of nitride stays in the corner of the pyramid, functioning as a ‘stop'. When this is removed, the silicon underneath is etched through the tiny hole. Automatically, a structure is formed alongside the silicon crystal plane. This is the first octahedron, formed by ‘auto alignment'. The process is repeated with a new layer of silicon nitride. The size of the new octahedra is determined by the etch period. In this case, every octahedron in the next step is half the size of the previous one. The advantage of corner lithography is its relative simplicity. No advanced technology is needed to create each individual nano pore. On the contrary: in just four steps thousands of fractals, each having 625 tiny holes can be processed on a wafer, in parallel. More than four steps is also possible, but this places higher demands on the etching process.

The research has been performed in the Transducers Science and Technology group, which is part of the MESA+ Institute for Nanotechnology of the University of Twente.

####

For more information, please click here

Contacts:

Wiebe van der Veen

+31612185692

Copyright © AlphaGalileo

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() Full bibliographic information

Full bibliographic information

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Nanomedicine

![]() New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Nanobiotechnology

![]() New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Ben-Gurion University of the Negev researchers several steps closer to harnessing patient's own T-cells to fight off cancer June 6th, 2025

Ben-Gurion University of the Negev researchers several steps closer to harnessing patient's own T-cells to fight off cancer June 6th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||