Home > Press > Do-it-yourself invisibility with 3-D printing

|

Abstract:

Seven years ago, Duke University engineers demonstrated the first working invisibility cloak in complex laboratory experiments. Now it appears creating a simple cloak has become a lot simpler.

Do-it-yourself invisibility with 3-D printing

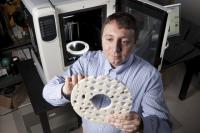

Durham, NC | Posted on May 6th, 2013"I would argue that essentially anyone who can spend a couple thousand dollars on a non-industry grade 3-D printer can literally make a plastic cloak overnight," said Yaroslav Urzhumov, assistant research professor in electrical and computer engineering at Duke's Pratt School of Engineering.

Three-dimensional printing, technically known as stereolithographic fabrication, has become increasingly popular, not only among industry, but for personal use. It involves a moving nozzle guided by a computer program laying down successive thin layers of a material -- usually a polymer plastic -- until a three-dimensional object is produced.

Urzhumov said that producing a cloak in this fashion is inexpensive and easy. He and his team made a small one at Duke which looks like a Frisbee™ disc made out of Swiss cheese. Algorithms determined the location, size and shape of the holes to deflect microwave beams. The fabrication process takes from three to seven hours.

The results of Urzhumov's experiments were published online in the journal Optics Letters, and the team's research was supported by the U.S. Army Research Office through a Multidisciplinary University Research Initiative grant.

Just like the 2006 cloak, the newer version deflects microwave beams, but researchers feel confident that in the not-so-distant future, the cloak can work for higher wavelengths, including visible light.

"We believe this approach is a way towards optical cloaking, including visible and infrared," Urzhumov said. "And nanotechnology is available to make these cloaks from transparent polymers or glass. The properties of transparent polymers and glasses are not that different from what we have in our polymer at microwave frequencies."

The disk-like cloak has an open area in its center where the researchers placed an opaque object. When microwave beams were aimed at the object through the side of the disk, the cloak made it appear that the object was not there.

"The design of the cloak eliminates the 'shadow' that would be cast, and suppresses the scattering from the object that would be expected," said Urzhumov. "In effect, the bright, highly reflective object, like a metal cylinder, is made invisible. The microwaves are carefully guided by a thin dielectric shell and then re-radiated back into free space on the shadow side of the cloak."

Urzhumov said that theoretically, the technique can be used to create much larger devices.

"Computer simulations make me believe that it is possible to create a similar polymer-based cloaking layer as thin as one inch wrapped around a massive object several meters in diameter," he said. "I have run some simulations that seem to confirm this point."

###

Other members of the team included Duke's Nathan Landy and David R. Smith, as well as Tom Driscoll and Dimitri Basov at the University of California - San Diego.

CITATION: "Thin Low-Loss Dielectric Coatings for Free-Space Cloaking," Y. Urzhumov, et al. Optics Letters. Online May 3, 2013. DOI 10.1364/OL.38.001606.

####

For more information, please click here

Contacts:

This is Yaroslav Urzhumov.

Credit: Duke University Photography

Copyright © Duke University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

3D & 4D printing/Additive-manufacturing

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

![]() 3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Printing/Lithography/Inkjet/Inks/Bio-printing/Dyes

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

![]() Disposable electronics on a simple sheet of paper October 7th, 2022

Disposable electronics on a simple sheet of paper October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||