Home > Press > Nanoifibers clean sulfur from fuel

|

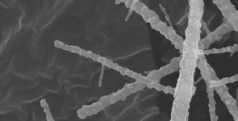

| Photo by Prashant Jain

Nanofibers of metal oxide provide lots of highly reactive surface area for scrubbing sulfur compounds from fuel. Sulfur has to be removed because it emits toxic gasses and corrodes catalysts. |

Abstract:

Sulfur compounds in petroleum fuels have met their nano-structured match.

University of Illinois researchers developed mats of metal oxide nanofibers that scrub sulfur from petroleum-based fuels much more effectively than traditional materials. Such efficiency could lower costs and improve performance for fuel-based catalysis, advanced energy applications and toxic gas removal.

Nanoifibers clean sulfur from fuel

Champaign, IL | Posted on December 17th, 2012Co-led by Mark Shannon, a professor of mechanical science and engineering at the U. of I. until his death this fall, and chemistry professor Prashant Jain, the researchers demonstrated their material in the journal Nature Nanotechnology.

Sulfur compounds in fuels cause problems on two fronts: They release toxic gases during combustion, and they damage metals and catalysts in engines and fuel cells. They usually are removed using a liquid treatment that adsorbs the sulfur from the fuel, but the process is cumbersome and requires that the fuel be cooled and reheated, making the fuel less energy efficient.

To solve these problems, researchers have turned to solid metal oxide adsorbents, but those have their own sets of challenges. While they work at high temperatures, eliminating the need to cool and re-heat the fuel, their performance is limited by stability issues. They lose their activity after only a few cycles of use.

Previous studies found that sulfur adsorption works best at the surface of solid metal oxides, so graduate student Mayank Behl, from Jain's group, and Junghoon Yeom, then a postdoctoral researcher in Shannon's group, set out to create a material with maximum surface area. The solution: tiny grains of zinc titanate spun into nanofibers, uniting high surface area, high reactivity and structural integrity in a high-performance sulfur adsorbent.

The nanofiber material is more reactive than the same material in bulk form, enabling complete sulfur removal with less material, allowing for a smaller reactor. The material stays stable and active after several cycles. Furthermore, the fibrous structure grants the material immunity from the problem of sintering, or clumping, that plagues other nano-structured catalysts.

"Our nanostructured fibers do not sinter," Jain said. "The fibrous structure accommodates any thermophysical changes without resulting in any degradation of the material. In fact, under operating conditions, nanobranches grow from the parent fibers, enhancing the surface area during operation."

Jain's group will continue to investigate the enhanced properties of nanofiber structures, hoping to gain an atomic-level understanding of what makes the material so effective.

"We are interested in finding out the atomic sites on the surface of the material where the hydrogen sulfide adsorbs," said Jain, who is also affiliated with the Beckman Institute for Advanced Science and Technology at the U. of I. "If we can know the identity of these sites, we could engineer an even more efficient adsorbent material. The atomic or nanoscale insight we gain from this material system could be useful to design other catalysts in renewable energy and toxic gas removal applications."

This work was supported by the National Science Foundation, the department of chemistry and the Frederick Seitz Materials Research Laboratory at the U. of I.

####

For more information, please click here

Contacts:

Liz Ahlberg

Physical Sciences Editor

217-244-1073

Prashant Jain

217-333-3417

Copyright © University of Illinois at Urbana-Champaign

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

Chemistry

![]() Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||