Home > Press > Penn Researchers Find New Way to Prevent Cracking in Nanoparticle Films

|

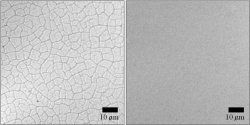

| Nanoparticle films crack at certain thicknesses (left). By adding layers of thinner films, cracking can be avoided (right). |

Abstract:

Making uniform coatings is a common engineering challenge, and, when working at the nanoscale, even the tiniest cracks or defects can be a big problem. New research from University of Pennsylvania engineers has shown a new way of avoiding such cracks when depositing thin films of nanoparticles.

Penn Researchers Find New Way to Prevent Cracking in Nanoparticle Films

Philadelphia, PA | Posted on October 15th, 2012The research was led by graduate student Jacob Prosser and assistant professor Daeyeon Lee, both of the Department of Chemical and Biomolecular Engineering in Penn's School of Engineering and Applied Science. Graduate student Teresa Brugarolas and undergraduate student Steven Lee, also of Chemical and Biomolecular Engineering, and professor Adam Nolte of the Rose-Hulman Institute of Technology participated in the research.

Their work was published in the journal Nano Letters.

To generate a nanoparticle film, the desired particles are suspended in a suitable liquid, which is then thinly and evenly spread over the surface through a variety of physical methods. The liquid is then allowed to evaporate, but, as it dries, the film can crack like mud in the sun.

"One method for preventing cracking is modifying the suspension's chemistry by putting binding additives in there," Prosser said. "But that is essentially adding a new material to the film, which may ruin its properties."

This dilemma is highlighted in the case of electrodes, the contact points in many electrical devices that transfer electricity. High-end devices, like certain types of solar cells, have electrodes composed of nanoparticle films that conduct electrons, but cracks in the films act as insulators. Adding a binder to the films would only compound the problem.

"These binders are usually polymers, which are insulators themselves," Lee said. "If you use them, you're not going to get the targeted property, the conductivity, that you want."

Engineers can prevent cracks with alternative drying methods, but these involve ultra-high temperatures or pressures and thus expensive and complicated equipment. A cheap and efficient method for preventing cracks would be a boon for any number of industrial processes.

The ubiquity of cracking in this context, however, means that researchers know the "critical cracking thickness" for many materials. The breakthrough came when Prosser tried making a film thinner than this threshold, then stacking them together to make a composite of the desired thickness.

"I was thinking about how, in the painting of buildings and homes, multiple coats are used," Prosser said. "One reason for that is to avoid cracking and peeling. I thought it could work for these films as well, so I gave it a try."

"This is one of those things where, once you figure it out," Lee said, "it's so obvious, but somehow this method has evaded everyone all these years."

One reason this approach may have remained untried is that it is counterintuitive that it should work at all.

The method the researchers used to make the films is known as "spin-coating." A precise amount of the nanoparticle suspension — in this case, silica spheres in water — is spread over the target surface. The surface is then rapidly spun, causing centrifugal acceleration to thin the suspension over the surface in a uniform layer. The suspension then dries with continued rotation, causing the water to evaporate and leaving the silica spheres behind in a compacted arrangement.

But to make a second layer over this first, another drop of liquid suspension would need to be placed on the dried nanoparticles, something that would normally wash them away. However, the researchers were surprised when the dried layers remained intact after the process was repeated 13 times; the exact mechanism by which they remained stable is something of a mystery.

"We believe that the nanoparticles are staying on the surface," Lee said, "because covalent bonds are being formed between them even though we're not exposing them to high temperatures. The inspiration for that hypothesis came from our colleague Rob Carpick. His recent Nature paper was all about how silica-silica surfaces form bonds at room temperature; we think this will work with other kinds of metal oxides."

Future research will be necessary to pin down this mechanism and apply it to new types of nanoparticles.

The research was supported by the National Science Foundation and the Penn Materials Research Science and Engineering Center.

####

For more information, please click here

Contacts:

Office of University Communications

200 Sansom Place East

3600 Chestnut Street

Philadelphia, PA

19104-6106

215-898-8721

Copyright © University of Pennsylvania

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Thin films

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

![]() New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Research partnerships

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() 'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||