Home > Press > 3D-Printer with Nano-Precision: Ultra-high-resolution 3D Printer Breaks Speed-Records at Vienna University of Technology.

|

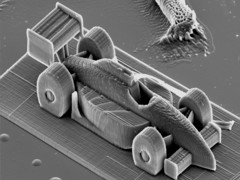

| A 285 µm racecar, printed at the Vienna University of Technology |

Abstract:

Printing three dimensional objects with incredibly fine details is now possible using "two-photon lithography". With this technology, tiny structures on a nanometer scale can be fabricated. Researchers at the Vienna University of Technology (TU Vienna) have now made a major breakthrough in speeding up this printing technique: The high-precision-3D-printer at TU Vienna is orders of magnitude faster than similar devices (see video). This opens up completely new areas of application, such as in medicine.

The video shows the 3d-printing process in real time. Due to the very fast guiding of the laser beam, 100 layers, consisting of approximately 200 single lines each, are produced in four minutes.

3D-Printer with Nano-Precision: Ultra-high-resolution 3D Printer Breaks Speed-Records at Vienna University of Technology.

Vienna, Austria | Posted on March 13th, 2012Setting a New World Record

The 3D printer uses a liquid resin, which is hardened at precisely the correct spots by a focused laser beam. The focal point of the laser beam is guided through the resin by movable mirrors and leaves behind a polymerized line of solid polymer, just a few hundred nanometers wide. This high resolution enables the creation of intricately structured sculptures as tiny as a grain of sand. "Until now, this technique used to be quite slow", says Professor Jürgen Stampfl from the Institute of Materials Science and Technology at the TU Vienna. "The printing speed used to be measured in millimeters per second - our device can do five meters in one second." In two-photon lithography, this is a world record.

This amazing progress was made possible by combining several new ideas. "It was crucial to improve the control mechanism of the mirrors", says Jan Torgersen (TU Vienna). The mirrors are continuously in motion during the printing process. The acceleration and deceleration-periods have to be tuned very precisely to achieve high-resolution results at a record-breaking speed.

Photoactive Molecules Harden the Resin

3D-printing is not all about mechanics - chemists had a crucial role to play in this project too. "The resin contains molecules, which are activated by the laser light. They induce a chain reaction in other components of the resin, so-called monomers, and turn them into a solid", says Jan Torgersen. These initiator molecules are only activated if they absorb two photons of the laser beam at once - and this only happens in the very center of the laser beam, where the intensity is highest. In contrast to conventional 3D-printing techniques, solid material can be created anywhere within the liquid resin rather than on top of the previously created layer only. Therefore, the working surface does not have to be specially prepared before the next layer can be produced (see Video), which saves a lot of time. A team of chemists led by Professor Robert Liska (TU Vienna) developed the suitable initiators for this special resin.

Researchers all over the world are working on 3D printers today - at universities as well as in industry. "Our competitive edge here at the Vienna University of Technology comes from the fact that we have experts from very different fields, working on different parts of the problem, at one single university", Jürgen Stampfl emphasizes. In materials science, process engineering or the optimization of light sources, there are experts working together and coming up with mutually stimulating ideas.

Because of the dramatically increased speed, much larger objects can now be created in a given period of time. This makes two-photon-lithography an interesting technique for industry. At the TU Vienna, scientists are now developing bio-compatible resins for medical applications. They can be used to create scaffolds to which living cells can attach themselves facilitating the systematic creation of biological tissues. The 3d printer could also be used to create tailor made construction parts for biomedical technology or nanotechnology.

####

For more information, please click here

Contacts:

Florian Aigner

43-158-801-41027

Jan Torgersen

Additive Manufacturing Technologies

Vienna University of Technology

T.: +43-1-58801-30869

Prof. Jürgen Stampfl

Additive Manufacturing Technologies

Vienna University of Technology

T.: +43-1-58801-30862

Copyright © Vienna University of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navys quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navys quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

3D & 4D printing/Additive-manufacturing

![]() Presenting: Ultrasound-based printing of 3D materialspotentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materialspotentially inside the body December 8th, 2023

![]() Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

![]() 3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Nanomedicine

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

![]() Researchers develop artificial building blocks of life March 8th, 2024

Researchers develop artificial building blocks of life March 8th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navys quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navys quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||