Home > Press > Microfluidics: Silicon valves operate at high pressures

|

Abstract:

Currently commercially available valves designed for micro-hydraulic systems are purely mechanical constructions and do not provide the degree of tightness necessary to efficiently regulate the flow of fluids under pressure of many atmospheres. Micromechanical valves made in silicon, using technologies employed in the processing of semiconductor materials, have been built at the Institute of Electron Technology (ITE) in Warsaw. "Our silicon microvalves provide tightness up to microlitres per minute for pressures of the order of a few dozen atmospheres. We believe there is still some room for improvement," says Paweł Kowalski, engineer at ITE, one of the designers.

Microfluidics: Silicon valves operate at high pressures

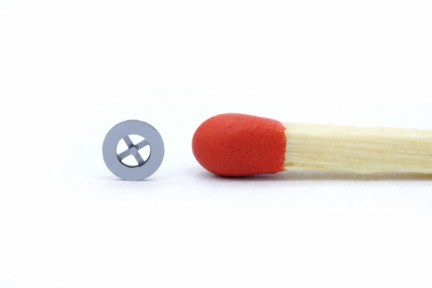

Warsaw, Poland | Posted on January 12th, 2012Two silicon microvalves have been built at the Institute of Electron Technology: a check valve, which does not require any control, and a through-flow valve, electronically controlled by means of a piezoelectric stack. The devices belong to a category of micromechanical systems known as MEMS (Micro Electro-Mechanical Systems). The key elements of both of them are silicon membranes and specially shaped sockets made with micrometre accuracy.

In the check valve, pressure applied in the direction of the flow causes the silicon membrane to deform, allowing liquid or gas to flow freely. Pressure applied in the opposite direction presses the membrane against an inlet opening, blocking it. The sensitivity of the valve and the pressure range depend on the thickness of silicon brackets holding the membrane in place over the opening. "The main advantage of the valve is its extremely simple construction," argues Kowalski.

In the electronically controlled valve, the silicon membrane is propped against a piezoelectric stack. Depending on the applied voltage, the stack expands or contracts, deforming the membrane and shutting off or allowing the flow of liquid. If the stack is powered by a voltage of 24 V, the valve will operate at pressures up to 50 atmospheres. In case of a voltage of 150 V, the pressures can reach up to 200 atmospheres. The pressure range can also be expanded without increasing the voltage, by increasing the size of the piezoelectric stack.

The silicon elements of both valves are the result of consecutive processes of plasma etching, photolithography and deposition of silicon and aluminium oxides. The advanced production technologies of the working elements of the valves, typical for production processes of electronic systems, are by no means cheap. Nevertheless, up to several dozen working elements can be produced out of a single silicon plate in a single production cycle, which significantly reduces the unit price. The finished silicon elements of the valves are then mounted in metal casings.

Works on the silicon microfluid valves have been financed from the statutory funds of the Institute of Electron Technology.

####

About ITE - Instytut Technologii Elektronowej

The Institute of Electron Technology in Warsaw (ITE) carries out research in the field of electronics and solid-state physics. It develops, implements and popularizes state-of-the-art micro and nanotechnologies in photonics and micro and nanoelectronics. The Institute focuses on optoelectronic detectors and radiation sources, state-of-the-art semiconductor lasers, micro and nanoprobes, nuclear radiation detectors, microsystems and sensors for interdisciplinary applications, as well as application-specific integrated circuits ASIC. In order to allow easier access to the technology, construction and measurement services for industrial and science and research units, the Institute has established the Centre of Nanophotonics, the Centre of Nanosystems and Microelectronic Technologies and the Laboratory for Multilayer and Ceramic Technologies.

For more information, please click here

Contacts:

Paweł Kowalski

Institute of Electron Technology

+48 22 5487962

Copyright © AlphaGalileo

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Microfluidics/Nanofluidics

![]() Implantable device shrinks pancreatic tumors: Taming pancreatic cancer with intratumoral immunotherapy April 14th, 2023

Implantable device shrinks pancreatic tumors: Taming pancreatic cancer with intratumoral immunotherapy April 14th, 2023

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

![]() Oregon State University research pushes closer to new therapy for pancreatic cancer May 6th, 2022

Oregon State University research pushes closer to new therapy for pancreatic cancer May 6th, 2022

Discoveries

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Announcements

![]() Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Battery Technology/Capacitors/Generators/Piezoelectrics/Thermoelectrics/Energy storage

![]() Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Deciphering local microstrain-induced optimization of asymmetric Fe single atomic sites for efficient oxygen reduction August 8th, 2025

Deciphering local microstrain-induced optimization of asymmetric Fe single atomic sites for efficient oxygen reduction August 8th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||