Home > Press > A Misunderstanding Leads to Method for Making Nanowells

|

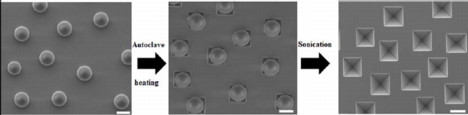

| Erik Hsiao Localized etching of a silicon (100) wafer upon hydrolysis of amidine-functionalized polystyrene latex colloids. The nanowell size can be precisely controlled with the size of the APSL colloids. No etch mask is needed and the region outside the nanowells is not etched at all. Scale Bar = 500 nm. |

Abstract:

A safe, simple, and cheap method of creating perfectly etched micron and smaller size wells in a variety of substrates has been developed by researchers in Penn State's Department of Chemical Engineering. Similar patterned surfaces are currently made using complex and expensive photolithography methods and etch processes under clean room conditions and used in the fabrication of many optical, electrical, and mechanical devices.

A Misunderstanding Leads to Method for Making Nanowells

University Park, PA | Posted on March 5th, 2011The nanowell discovery was made in the labs of Darrell Velegol and Seong Kim by Velegol's graduate student, Neetu Chaturvedi, and Kim's graduate student, Erik Hsiao. An article detailing their research, "Maskless Fabrication of Nanowells Using Chemically Reactive Colloids," appeared in the online edition of the journal Nano Letters in January 2011. In collaboration with Chaturvedi, Hsiao was working on a project to adhere polystyrene on a silicon wafer to create nanostructures with known dimensions. When Hsiao asked her to heat one of his samples, a miscommunication led her to heat the polystyrene and silicon wafer at low temperature in water in the autoclave normally used for biological samples rather than in the vacuum furnace. When they looked at the samples under the atomic force microscope (AFM), they noticed holes had formed beneath the polystyrene particles. Further examination under the scanning electron microscope (SEM) showed them perfectly etched, pyramidal shaped holes in the substrate below the places where the amidine-functionalized polystyrene latex colloid particles had adhered to the silicon dioxide on the surface of the silicon wafer.

"We saw three holes in the sample at the first AFM imaging and didn't know what it meant since we expected pancake-like polymer patches on the sample," said Hsiao. They took the sample to their advisers, who were both surprised by the etched wafer. By going over the steps the students had taken, the researchers realized that the wells were produced when the water hydrolized the amidine group in the particle, and through a series of chemical reactions, created a hydroxide ion that etched the well into the silicon wafer. The holes were uniform and their size and depth were totally dependent on the size of the original polystyrene particle, although the orientation of the silicon crystal affected the shape of the wells. In one orientation (100), the wells were perfect four-sided inverted pyramids. In the other orientation (111), the wells were perfect hexagons. The four researchers called them nanowells, because the bottom dimension of the wells was only a couple of nanometers across. They soon realized that they had discovered a new maskless method for creating structures in silicon without the elaborate steps normally required in the clean room.

"We're delivering hydroxide ions directly to where we want to etch," Velegol explained. "It's much safer and cheaper than electron beam and X-ray lithography. It's so safe that you could practically eat these particles without any harm."

"We think this is a quite general discovery," Kim added. "It's a way to deliver chemistry locally rather than in bulk. Many metals, ceramics, and other materials can be etched with this technique."

Another potential benefit of the discovery is the ability to create patterns on curved surfaces, something that is difficult to do with conventional photolithography. Since the particles are suspended in water, they can adhere to the surface of any shape and space themselves evenly over the surface. The researchers are just beginning to come up with intriguing ideas for how to use the simple technique.

Many breakthroughs come from accidents, Velegol remarked, because once something is known, people work on it very rapidly until they have filled in all the pieces and there is less to discover. Accidents are out of the pattern. "It's one of those situations like Pasteur said where chance favors the prepared mind. We would never even have thought to try this kind of chemistry. But Neetu had been working with these colloids for several years, and Erik had experience with the AFM, so they were well prepared to take advantage of the accident," Velegol concluded.

Neetu Chaturvedi, Ph.D., recently defended her thesis and is now a researcher with DuPont. Erik Hsiao is a graduate student in chemical engineering. Darrell Velegol is professor of chemical engineering and Seong Kim is associate professor of chemical engineering. Both are faculty in the Materials Research Institute where the AFM and SEM work was performed. Contact them by email at and This work was supported by the National Science Foundation (Grant Nos. IDR-1014673 and CMMI-1000021).

####

About Penn State Materials Research Institute

The Materials Research Institute facilitates and coordinates Penn State’s interdisciplinary research activity in materials science and engineering. The Millennium Science Complex, the university’s largest facility for scientific research, is scheduled to open in July 2011. It will bring together the Materials Research Institute and the Huck Institutes of the Life Sciences in the integration of the physical and life sciences with engineering.

For more information, please click here

Contacts:

Penn State Materials Research Institute

News office:

Pennsylvania State University

108 Materials Research Laboratory

University Park PA 16802

814-865-0285

Walter Mills

Associate Editor Publications

Materials Science

814-865-0285

Copyright © Penn State Materials Research Institute

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Grants/Sponsored Research/Awards/Scholarships/Gifts/Contests/Honors/Records

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||