Home > Press > MesoCoat, Inc. Begins Developing Nanocomposite Coatings for Zinc Pot Rolls that Perform 2-7X Better than Current Materials

|

Abstract:

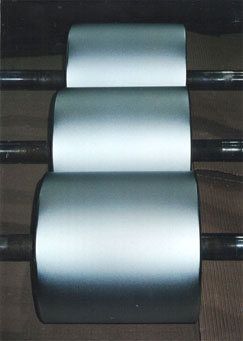

MesoCoat, Inc. announced today the development of nanocomposite coating materials, which have shown promise to extend the life of zinc pot rolls and other metal processing and forming tools and equipment by 2-7X to that of current Tungsten Carbide or Stellite coatings.

MesoCoat, Inc. Begins Developing Nanocomposite Coatings for Zinc Pot Rolls that Perform 2-7X Better than Current Materials

Euclid, OH | Posted on August 19th, 2010There are about 57 hot galvanized sheet strip production lines in the USA, and the losses caused by zinc corrosion approach $500 million a year. Typical galvanizing operations experience downtimes on the order of every two weeks to change the metallic hardware submerged in the molten metal bath. This is an expensive process for the industry since it takes upwards of three days for a complete turnaround to resume normal operation. There is a need to restrain or reduce the corrosion in order to shorten downtime, improve the quality of coated steel and reduce the cost and frequency of replacing zinc pot rolls. To solve the problem of high costs and lost productivity due to corrosion, MesoCoat is developing high toughness, self-lubricating coatings that are resistant to harsh liquid metal corrosion and environmental wear.

To address these needs, MesoCoat is developing nanocomposite coatings that will extend the life of metal forming and processing tools and equipment in severely corrosive environments. To further validate the success of this technology, MesoCoat's nanocomposite coating technology was selected against stiff competition to win a $1 million Small Business Innovation Research (SBIR) Phase II contract from the Department of Energy (DOE). With this award, MesoCoat will complete development and validation testing of the self-lubricating nanocomposite coating materials for metal forming and processing tools and equipment, resulting in commercial availability of the life extending, cost reducing nanocomposite coating technology within the next two years.

Andrew Sherman (CEO, MesoCoat, Inc.) stated, "Each of the galvanizing lines in the US uses 10 rolls at a time with a typical four day replacement cycle. This means there is a demand for resurfacing/refurbishing roughly 25,000 rolls per year at a typical cost of $4,000/roll or a total current market of roughly $100,000,000 per year. Life improvement of molten metal bath hardware in continuous galvanizing lines is projected to result in an extension of component life by an order of magnitude, estimated energy savings of two trillion BTU/year and cost savings of approximately $46 million/year for the 57 galvanizing lines operating in the United States. This is a significant opportunity and we are confident of achieving at least a 20% market share in this $100 million market with our innovative solutions. MesoCoat is actively seeking alpha and beta verification and testing partners, as well as value chain partners in the metal forming and process industry who can benefit from the availability of this nanocomposite coating technology."

####

About MesoCoat

MesoCoat, Inc. is an Ohio based surface engineering company that is uniquely positioned to capture the mantle of leadership in metal asset protection and life extension; through their revolutionary ‘long life’ coatings and ‘high speed' cladding application technologies. The company and the core technologies for the ceramic-metallic products and high speed cladding have already been the recipient of three prestigious R&D 100 awards, a Technology Innovation Award (TIP) for 100 year life coatings by the National Institute of Standards and Technology (NIST), and the NorTech Innovation Award for developing high performance environmentally friendly coating materials.

Partnering with the Departments of Defense and Energy as well as some of the biggest names in Oil & Gas, Aerospace and Maritime; MesoCoat has developed high strength, high toughness ceramic-metallic materials with unparalleled wear and corrosion resistance. MesoCoat is taking significant strides to own the title of "Best in Class" for corrosion, wear, and erosion protection in the industrial, commercial, defense and infrastructure sectors. Significant advantages in base material protection, service life, application efficiency and total cost of ownership provide an arsenal of market levers that will be difficult for competitors to match. MesoCoat is now commercializing several of their products that are a direct replacement for chrome plating, tungsten carbide, and other carbide coatings into several industries addressing the needs of both Original Equipment Manufacturers (OEM) and Maintenance and Repair Organizations (MRO). MesoCoat, Inc.is a JumpStart, Inc. and Abakan, Inc. Portfolio Company.

For more information, please click here

Contacts:

Anupam Ghildyal

Phone: 2164530866

Fax: 2164040054

Copyright © MesoCoat

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Products

![]() Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

![]() Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

![]() Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

![]() Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Grants/Sponsored Research/Awards/Scholarships/Gifts/Contests/Honors/Records

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||