Home > Press > Semiconductor manufacturing technique holds promise for solar energy

|

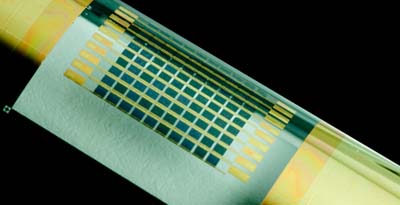

| A flexible array of gallium arsenide solar cells. Gallium arsenide and other compound semiconductors are more efficient than the more commonly used silicon. Photo courtesy John Rogers |

Abstract:

Thanks to a new semiconductor manufacturing method pioneered at the University of Illinois, the future of solar energy just got brighter

Semiconductor manufacturing technique holds promise for solar energy

Champaign, IL | Posted on May 20th, 2010Although silicon is the industry standard semiconductor in most electronic devices, including the photovoltaic cells that solar panels use to convert sunlight into energy, it is hardly the most efficient material available. For example, the semiconductor gallium arsenide and related compound semiconductors offer nearly twice the efficiency as silicon in solar devices, yet they are rarely used in utility-scale applications because of their high manufacturing cost.

U. of I. professors John Rogers and Xiuling Li explored lower-cost ways to manufacture thin films of gallium arsenide that also allowed versatility in the types of devices they could be incorporated into. "If you can reduce substantially the cost of gallium arsenide and other compound semiconductors, then you could expand their range of applications," said Rogers, the Lee J. Flory Founder Chair in Engineering Innovation, and a professor of materials science and engineering and of chemistry.

Typically, gallium arsenide is deposited in a single thin layer on a small wafer. Either the desired device is made directly on the wafer, or the semiconductor-coated wafer is cut up into chips of the desired size. The Illinois group decided to deposit multiple layers of the material on a single wafer, creating a layered, "pancake" stack of gallium arsenide thin films.

"If you grow 10 layers in one growth, you only have to load the wafer one time," said Li, a professor of electrical and computer engineering. "If you do this in 10 growths, loading and unloading with temperature ramp-up and ramp-down take a lot of time. If you consider what is required for each growth - the machine, the preparation, the time, the people - the overhead saving our approach offers is a significant cost reduction."

Next the researchers individually peel off the layers and transfer them. To accomplish this, the stacks alternate layers of aluminum arsenide with the gallium arsenide. Bathing the stacks in a solution of acid and an oxidizing agent dissolves the layers of aluminum arsenide, freeing the individual thin sheets of gallium arsenide. A soft stamp-like device picks up the layers, one at a time from the top down, for transfer to another substrate - glass, plastic or silicon, depending on the application. Then the wafer can be reused for another growth.

"By doing this we can generate much more material more rapidly and more cost effectively," Rogers said. "We're creating bulk quantities of material, as opposed to just the thin single-layer manner in which it is typically grown."

Freeing the material from the wafer also opens the possibility of flexible, thin-film electronics made with gallium arsenide or other high-speed semiconductors. "To make devices that can conform but still retain high performance, that's significant," Li said.

In a paper to be published online May 20 in the journal Nature, the group describes its methods and demonstrates three types of devices using gallium arsenide chips manufactured in multilayer stacks: light sensors, high-speed transistors and solar cells. The authors also provide a detailed cost comparison.

Another advantage of the multilayer technique is the release from area constraints, especially important for solar cells. As the layers are removed from the stack, they can be laid out side-by-side on another substrate to produce a much larger surface area, whereas the typical single-layer process limits area to the size of the wafer.

"For photovoltaics, you want large area coverage to catch as much sunlight as possible. In an extreme case we might grow enough layers to have 10 times the area of the conventional route," Rogers said.

"You really multiply the area coverage, and by a similar multiplier you reduce the cost, while at the same time eliminating the consumption of the wafer," he said.

Among the paper's co-authors are two scientists from Semprius Inc., a North Carolina-based startup company that is beginning to use this technique to manufacture solar cells. A shift from silicon-based panels to more efficient gallium arsenide models could make solar power a more cost-effective form of alternative energy.

Next, the group plans to explore more potential device applications and other semiconductor materials that could adapt to multilayer growth.

The Department of Energy and National Science Foundation-funded team also includes U. of I. postdoctoral researchers Jongseung Yoon, Sungjin Jo and Inhwa Jung; students Ik Su Chun and Hoon-Sik Kin; and electrical and computer engineering professor James Coleman, along with Ungyu Paik, of Hanyang University in Seoul, and Semprius scientists Matthew Meitl and Etienne Menard.

####

For more information, please click here

Contacts:

Liz Ahlberg

Physical Sciences Editor

217-244-1073

Copyright © University of Illinois

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Thin films

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

![]() New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Academic/Education

![]() Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

![]() Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Energy

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

Solar/Photovoltaic

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||