Home > Press > Tiny owls take flight

|

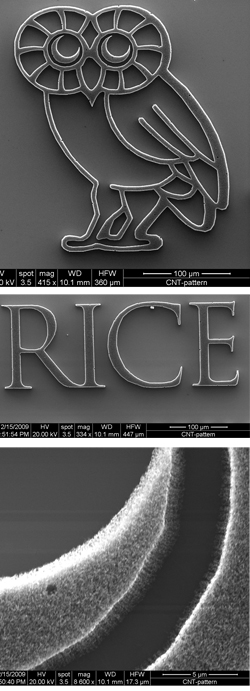

| Graduate students Jun Yao and Noe Alvarez grew millions of carbon nanotubes to produce the Rice Owl and wordmark, seen through an electron scanning microscope. The bottom photo shows the forest of tubes that make up the owl's eye. PHOTOS BY JUN YAO, NOE ALVAREZ |

Abstract:

Grad students' nano-owls began as a lark, became fitting swan song

Tiny owls take flight

Houston, TX | Posted on December 30th, 2009There are so many cool things about these images that it's hard to know where to begin. First, they're very tiny - about twice the width of a human hair.

There's the fact that they're made of something much smaller: carbon nanotubes grown in carpets via a process developed at Rice. Each nanotube is about 50,000 times smaller than the diameter of a hair.

And then there's Jun Yao's steady hand. The Rice graduate student, at the behest of his friend and colleague Noe Alvarez, painstakingly drew the Rice Owl (as well as the wordmark) with a mouse, tracing the beloved image into a computer program that controls an electron beam.

The first nano-owls were designed by Yao, a student in the labs of James Tour, Doug Natelson and Lin Zhong, and grown by Alvarez, who recently earned his doctorate at Rice, to accompany the latter's thesis presentation. "I really wanted to use the Rice logo made of nanotubes on one of my slides for the Ph.D. defense committee, and we finished it in time, but the electron scanning microscope was broken," he recalled.

But Alvarez, who said he and Yao made the nano-owls for fun, still wanted to get a good look at their creations, which by his calculations consist of more than 10 million nanotubes. When he noticed the now-repaired microscope sitting idle earlier this week, he grabbed the opportunity to make a few portraits of the tiniest owl ever.

Yao explained the process involved layering a silicon wafer with a 10-nanometer-thick alumina substrate and a slim coating of liquid poly(methyl methacrylate), aka PMMA. "We bake this stuff at 180 degrees C for two minutes to crystallize the liquid," he said. "We already had the image in the computer, so we could have the e-beam trace the pattern into the PMMA."

They used a developer to wash away the PMMA that had been exposed to the electron beam, followed by deposition of a .5 nanometer iron catalyst film and then an acetone bath to remove the catalyst outside the nano-owl pattern. "Then we put it in the reactor, where the carpet grows in about 15 minutes," Alvarez said.

To the naked eye, the nano-owls are barely visible dots. "But if you compare this to a corn field, which typically has 30,000 plants per acre, the nano-owl alone is equivalent to 350 acres of corn plantation," he said.

Alvarez, who worked in the labs of co-advisers Tour and Robert Hauge, a pioneer in the growth of nanotubes bundles, will leave Rice soon for a postdoctoral position at Japan's National Institute of Advanced Industrial Science and Technology.

That makes his nano-owls a wonderful parting gift. And for that we give very large thanks.

####

For more information, please click here

Contacts:

B.J. Almond

Director, Department of News and Media Relations

Copyright © Rice University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||