Home > Press > IMEC’s spray-coating technique holds promise for cheap fully solution-processed organic solar cells

|

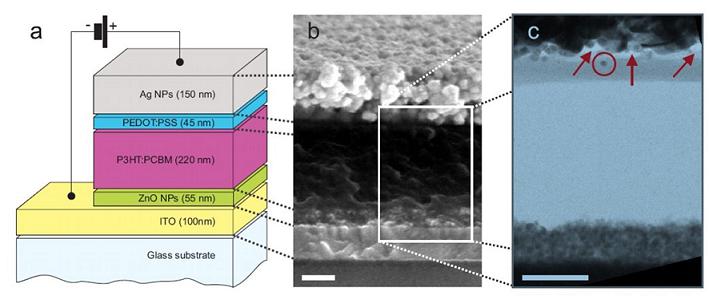

| Figure 1 - (a) Schematic build-up of the organic solar cell, (b) SEM and (c) FIB/TEM cross sections of the polymer solar cell with a spray coated Ag top contact. |

Abstract:

IMEC has demonstrated a fully solution-processed organic solar cell with a spray-coated active layer and a metal top contact spray-coated on top. The resulting cell shows power conversion efficiencies above 3%, a performance comparable to organic solar cells produced by spin coating of the organic layer and vacuum evaporation of the top contact metal. This is an important step towards producing organic solar cells with cheap and large-area processes.

IMEC’s spray-coating technique holds promise for cheap fully solution-processed organic solar cells

Leuven, Belgium | Posted on October 7th, 2009Polymer-based (organic) solar cells hold the promise of low-cost production and a high throughput. However, this can only become true if all the layers of the cells can be deposited by solution-based, in-line compatible methods. IMEC's research now shows that spray-coating is a suitable deposition technique, and that it can be used to deposit all layers, including the metal top contact.

Spray-coating is a high-rate, large-area deposition technique that ensures an ideal coating on a variety of surfaces with different morphologies and topographies. It is frequently used for industrial coating and in-line deposition processes. In spray-coating systems, the ink is atomized at the nozzle by pressure or ultrasound and then directed toward the substrate by a gas. An added advantage of spray-coating is that it is efficient: compared to other techniques only a small amount of the solutions are wasted.

IMEC demonstrated that an active layer - a solution of P3HT and PCBM - deposited with spray-coating shows power conversion efficiencies above 3%, a performance which is comparable to that of spin-coated devices. And for the metal top contact, IMEC spray-coated a solution with silver nanoparticles. The challenges are to do this without dissolving the underlying layer, and without damaging it by the temperature needed to sinter the silver nanoparticles. IMEC demonstrated that spray-coating greatly reduces the damage to underlying layers compared to other techniques. It was also able to sinter the silver nanoparticles at 150°C, a temperature that is compatible with processing on flexible substrates.

Tom Aernouts, Teamleader Organic Photovolatics at IMEC: "R&D on organic solar cells has entered the stage where we can consider low-cost high-volume manufacturing, which is essential for the uptake of this technology by the industry. Our results show that IMEC has the expertise and knowhow to play an important role in organic photovoltaics R&D."

####

About IMEC

IMEC performs world-leading research in nanotechnology. IMEC leverages its scientific knowledge with the innovative power of its industrial partners. In ICT, healthcare and energy, IMEC delivers industry-relevant technology solutions. In a unique high-tech environment, IMEC’s international top talent is committed to providing the building blocks for a better life in a sustainable society.

IMEC is headquartered in Leuven, Belgium, and has offices in Belgium, the Netherlands, Taiwan, US, China and Japan. Its staff of more than 1,650 people include over 550 industrial residents and guest researchers. In 2008, IMEC's revenue (P&L) was 270 million euro.

IMEC is a registered trademark for the activities of IMEC International (a legal entity set up under Belgian law as a "stichting van openbaar nut"), IMEC in Belgium (IMEC vzw supported by the Flemish Government), stichting IMEC Nederland (IMEC-NL) and IMEC Taiwan Co. (IMEC-TW).

For more information, please click here

Contacts:

IMEC: Katrien Marent

Director of External Communications

T: +32 16 28 18 80

M: +32 474 30 28 66

Barbara Kalkis

Maestro Marketing & PR

T: +1 408 996 9975

Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Products

![]() Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

![]() Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

![]() Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

![]() Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Solar/Photovoltaic

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||