Home > Press > Yale engineers revolutionize nano-device fabrication using amorphous metals

|

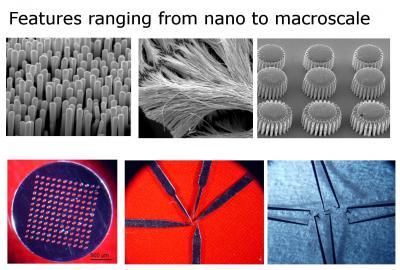

| Various parts (nano-molds, nano-wires, gears, membrane, scalpels, and tweezers) fabricated by molding metallic glass over wide range of length scales -- from 13 nm to several millimeters.

Credit: Kumar/Schroers(Yale) |

Abstract:

Yale engineers have created a process that may revolutionize the manufacture of nano-devices from computer memory to biomedical sensors by exploiting a novel type of metal. The material can be molded like plastics to create features at the nano-scale and yet is more durable and stronger than silicon or steel. The work is reported in the February 12 issue of Nature.

Yale engineers revolutionize nano-device fabrication using amorphous metals

New Haven, CT | Posted on February 11th, 2009The search for a cost-effective and manageable process for higher-density computer chip production at the nano-scale has been a challenge. One solution is making nano-scale devices by simple stamping or molding, like the method used for fabricating CDs or DVDs. This however requires stamps or master molds with nano-scale features. While silicon-based molds produce relatively fine detail, they are not very durable. Metals are stronger, but the grain size of their internal structure does not allow nano-scale details to be imprinted on their surfaces.

Unlike most metals, "amorphous metals" known as bulk metallic glasses (BMGs) do not form crystal structures when they are cooled rapidly after heating. Although they seem solid, they are more like a very slow-flowing liquid that has no structure beyond the atomic level — making them ideal for molding fine details, said senior author Jan Schroers of the Yale School of Engineering & Applied Science.

Researchers have been exploring the use of BMGs for about a decade, according to Schroers. "We have finally been able to harness their unusual properties to transform both the process of making molds and producing imprints," he said. "This process has the potential to replace several lithographic steps in the production of computer chips."

Schroers says BMGs have the pliability of plastics at moderately elevated temperatures, but they are stronger and more resilient than steel or metals at normal working temperatures.

"We now can make template molds that are far more reliable and lasting than ones made of silicon and are not limited in their detail by the grain size that most metals impose," said Schroers.

To actually get detail at the nano-scale the researchers had to overcome an issue faced in any molding process — how to get the material to cover the finest detail, and then how to separate the material intact from the mold. Surfaces of liquid metals exhibit high surface tension and capillary effects that can interfere in the molding.

Postdoctoral fellow Golden Kumar found that by altering the mold-BMG combination they could create surfaces so that the atoms take advantage of their favorable interaction with the mold— to both fill the mold and then release the product.

In this paper, Schroers' team reports nano-patterning of details as small as 13 nanometers— about one ten-thousandth the thickness of a human hair — and the scientists expect that even finer detail will be possible since the BMGs are only limited by the size of a single atom.

While ‘plastics!' was the catchword of the 1960's, Schroers says, "We think ‘BMGs!' will be the buzz-word for the coming decade."

Hong Tang, assistant professor of mechanical engineering and electrical engineering at Yale was also an author of the paper. Funding for this research was from the National Science Foundation.

Citation: Nature (January 12, 2009)

####

For more information, please click here

Contacts:

Janet Rettig Emanuel

203-432-2157

Copyright © Yale University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() Yale School of Engineering& Applied Science

Yale School of Engineering& Applied Science

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Memory Technology

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Researchers discover materials exhibiting huge magnetoresistance June 9th, 2023

Researchers discover materials exhibiting huge magnetoresistance June 9th, 2023

Sensors

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||