Home > Press > January 27, 2009 In This Issue: blue bullet For Refrigeration Problems, a Magnetically Attractive Solution blue bullet Taking the Stress

|

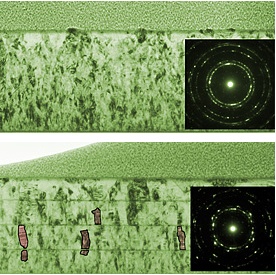

| Transmission electron microscope (TEM) images show sections of a continuous 400-nanometer-thick magnetic film of a nickle-iron-copper-molybdenum alloy (top) and a film of the same alloy layered with silver every 100 nanometers (bottom). By relieving strain in the film, the silver layers promote the growth of notably larger crystal grains in the layered material as compared to the monolithic film (several are highlighted for emphasis). Electron diffraction patterns (insets) tell a similar story—the material with larger crystal grains display sharper, more discrete scattering patterns. (Color added for clarity.)

Credit: Bonevich, NIST |

Abstract:

Researchers at the National Institute of Standards and Technology (NIST) have discovered that a carefully built magnetic sandwich that interleaves layers of a magnetic alloy with a few nanometers of silver "spacer" has dramatically enhanced sensitivity—a 400-fold improvement in some cases. This material could lead to greatly improved magnetic sensors for a wide range of applications from weapons detection and non-destructive testing to medical devices and high-performance data storage.

January 27, 2009 In This Issue: blue bullet For Refrigeration Problems, a Magnetically Attractive Solution blue bullet Taking the Stress

GAITHERSBURG, MD | Posted on January 28th, 2009Those applications and many others are based on thin films of magnetic materials in which the direction of magnetization can be switched from one orientation to another. An important characteristic of a magnetic film is its saturation field, the magnitude of the applied magnetic field that completely magnetizes the film in the same direction as the applied field—the smaller the saturation field, the more sensitive the device.

The saturation field is often determined by the amount of stress in the film—atoms under stress due to the pull of bonds with neighboring atoms are more resistant to changing their magnetic orientation. Metallic films develop not as a single monolithic crystal, like diamonds, but rather as a random mosaic of microscopic crystals called grains. Atoms on the boundaries between two different grains tend to be more stressed, so films with a lot of fine grains tend to have more internal stress than coarser grained films. Film stress also increases as the film is made thicker, which is unfortunate because thick films are often required for high magnetization applications.

The NIST research team discovered that magnetic film stress could be lowered dramatically by periodically adding a layer of a metal, having a different crystal structure or lattice spacing, in between the magnetic layers. Although the mechanism isn't completely understood, according to lead author William Egelhoff Jr., the intervening layers disrupt the magnetic film growth and induce the creation of new grains that grow to be larger than they do in the monolithic films. The researchers prepared multilayer films with layers of a nickel-iron-copper-molybdenum magnetic alloy each 100 nanometers (nm) thick, interleaved with 5-nm layers of silver. The structure reduced the tensile stress (over a monolithic film of equivalent thickness) by a factor of 200 and lowered the saturation field by a factor of 400.

The work has particular application in the design of "flux concentrators," magnetic structures that draw in external magnetic field lines and concentrate them in a small region. Flux concentrators are used to amplify fields in compact magnetic sensors used for a wide variety of applications.

* W.F. Egelhoff, Jr., J. Bonevich, P. Pong, C.R. Beauchamp, G.R. Stafford, J. Unguris, and R.D. McMichael. 400-fold reduction in saturation field by interlayering. J. Appl. Phys. 105, 013921 (2009). Published online Jan. 13, 2009. DOI:10.1063/1.3058673

####

About NIST

Founded in 1901, NIST is a non-regulatory federal agency within the U.S. Department of Commerce. NIST's mission is to promote U.S. innovation and industrial competitiveness by advancing measurement science, standards, and technology in ways that enhance economic security and improve our quality of life.

For more information, please click here

Contacts:

Michael Baum

(301) 975-2763

Copyright © NIST

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Memory Technology

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Researchers discover materials exhibiting huge magnetoresistance June 9th, 2023

Researchers discover materials exhibiting huge magnetoresistance June 9th, 2023

Sensors

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||