Home > Press > MIT creates gecko-inspired bandage

|

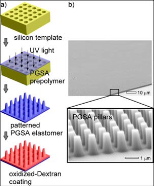

| MIT's gecko-inspired medical adhesive consists of a "biorubber" base patterned to have pillars that are less than a micrometer in diameter and three micrometers in height. Layered on top is a thin coating of a sugar-based glue. Tests in live rats suggest that the adhesive could be an effective operating room tool for closing surgical wounds. |

Abstract:

MIT researchers and colleagues have created a waterproof adhesive bandage inspired by gecko lizards that may soon join sutures and staples as a basic operating room tool for patching up surgical wounds or internal injuries.

MIT creates gecko-inspired bandage

Cambridge, MA | Posted on February 18th, 2008Drawing on some of the principles that make gecko feet unique, the surface of the bandage has the same kind of nanoscale hills and valleys that allow the lizards to cling to walls and ceilings. Layered over this landscape is a thin coating of glue that helps the bandage stick in wet environments, such as to heart, bladder or lung tissue. And because the bandage is biodegradable, it dissolves over time and does not have to be removed.

The team is led by MIT Institute Professor Robert Langer and Jeff Karp, an instructor of medicine at Brigham and Women's Hospital and Harvard Medical School. Both are also faculty members at the Harvard-MIT Division of Health Sciences and Technology (HST).

The work is described in the Feb. 11 online issue of the Proceedings of the National Academy of Sciences.

"There is a big need for a tape-based medical adhesive," said Karp. For instance, a surgical adhesive tape made from this new material could wrap around and reseal the intestine after the removal of a diseased segment or after a gastric bypass procedure. It could also patch a hole caused by an ulcer. Because it can be folded and unfolded, it has a potential application in minimally invasive surgical procedures that are particularly difficult to suture because they are performed through a very small incision.

Gecko-like dry adhesives have been around since about 2001 but there have been significant challenges to adapt this technology for medical applications given the strict design criteria required. For use in the body, they must be adapted to stick in a wet environment and be constructed from materials customized for medical applications. Such materials must be biocompatible, meaning they do not cause inflammation; biodegradable, meaning they dissolve over time without producing toxins; and elastic, so that they can conform to and stretch with the body's tissues.

The MIT researchers met these requirements by building their medical adhesive with a "biorubber" invented by Karp, Langer and others. Using micropatterning technology--the same technology used to create computer chips--the researchers shaped the biorubber into different hill and valley profiles at nanoscale dimensions. After testing them on intestinal tissue taken from pigs, they selected the stickiest profile, one with pillars spaced just wide enough to grip and interlock with the underlying tissue.

Karp then added a very thin layer of a sugar-based glue, to create a strong bond even to a wet surface. The resulting bandage "is something we never expect to remove," said Karp. Because of that difference, he continued, "we're not mimicking the gecko"--which has sticky feet but can still lift them up to walk--"we are inspired by the gecko to create a patterned interface to enhance the surface area of contact and thus the overall strength of adhesion."

When tested against the intestinal tissue samples from pigs, the nanopatterned adhesive bonds were twice as strong as unpatterned adhesives. In tests of the new adhesive in living rats, the glue-coated nanopatterned adhesive showed over a 100 percent increase in adhesive strength compared to the same material without the glue. Moreover, the rats showed only a mild inflammatory response to the adhesive, a minor reaction that does not need to be overcome for clinical use.

Among other advantages, the adhesive could be infused with drugs designed to release as the biorubber degrades. Further, the elasticity and degradation rate of the biorubber are tunable, as is the pillared landscape. This means that the new adhesives can be customized to have the right elasticity, resilience and grip for different medical applications.

"This is an exciting example of how nanostructures can be controlled, and in so doing, used to create a new family of adhesives," said Langer.

Other MIT authors of the paper are co-first authors Alborz Mahdavi, a former MIT lab technician now at the California Institute of Technology; Lino Ferreira, a former MIT postdoctoral fellow now at the University of Coimbra, Portugal; Jason W. Nichol and Edwin P. Chan, HST postdoctoral fellows; David J.D. Carter and Jeff Borenstein of Draper Laboratory; HST doctoral student Chris Bettinger; and MIT graduate students Siamrut Patanavanich, Loice Chignozha, Eli B. Joseph, Alex Galakatos and Seungpyo Hong, all from the Department of Chemical Engineering. Additional authors are from Massachusetts General Hospital and the University of Basel, Switzerland.

The work was funded by the National Institutes of Health, the Materials Research Science and Engineering Center (MRSEC) program of the National Science Foundation, and the MIT-Portugal program.

####

About MIT

The mission of MIT is to advance knowledge and educate students in science, technology, and other areas of scholarship that will best serve the nation and the world in the 21st century.

For more information, please click here

Contacts:

Elizabeth A. Thomson

MIT News Office

Phone: 617-258-5402

E-mail:

Copyright © MIT

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Nanomedicine

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

![]() Researchers develop artificial building blocks of life March 8th, 2024

Researchers develop artificial building blocks of life March 8th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||