Home > Press > 'One-pot' process can make more-efficient materials for fuel cells and solar cells

|

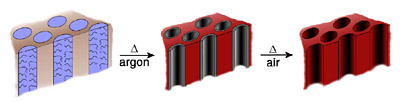

| Provided/Ulrich Wiesner In the CASH (combined assembly by soft and hard chemistries) process, a polymer forms itself into ordered rows of cylinders surrounded by a metal oxide. Heating in the absence of oxygen turns the polymer into a hard carbon framework that holds its shape while the metal oxide is heated to a higher temperature to make it form uniform crystals. Finally, heating in air burns off the carbon to leave a porous material. |

Abstract:

Cornell researchers have developed a "one-pot" process to create porous films of crystalline metal oxides that could lead to more-efficient fuel cells and solar cells.

'One-pot' process can make more-efficient materials for fuel cells and solar cells

ITHACA, NY | Posted on January 28th, 2008In a fuel cell, a material with nanoscale pores offers more surface area over which a fuel can interact with a catalyst. Similarly in solar cells, a porous material offers more surface area over which light can be absorbed, so more of it is converted to electricity.

Previously such porous materials have been made on hard templates of carbon or silica, or by using soft polymers that self-assemble into a foamy structure. Making a hard porous template and getting the metal oxides to distribute evenly through it is tedious. The polymer approach is easier and makes a good structure, but the metal oxides must be heated to high temperatures to fully crystallize, and this causes the polymer pores to collapse.

The Cornell researchers have combined what Ulrich Wiesner, Cornell professor of materials science and engineering, calls "the best of the two approaches," using a soft block copolymer called poly(isoprene-block-ethylene oxide) or PI-b-PEO that carbonizes when heated to high temperatures in an inert gas, providing a hard framework around which the metal oxide crystallizes. Subsequent heating in air burns away the carbon. Wiesner calls this "combined assembly by soft and hard chemistries," or CASH.

The research is described in an online paper in the journal Nature Materials by Wiesner, Francis DiSalvo, the J.A. Newman Professor of Chemistry and Chemical Biology, and colleagues.

The researchers created porous films of titanium oxide, used in solar cells, and niobium oxide, a potential fuel-cell catalyst support. Chemicals that will react to form the metal oxides and a solution of PI-b-PEO are combined. As the reaction proceeds, the PI portion of the copolymer forms cylinders some 20 nanometers across surrounded by metal oxides, and subsequent heat treatments leave uniform, highly crystalline metal oxide with cylindrical pores. The pores are neatly ordered in hexagonal patterns, which creates a larger surface area than if the pores were randomly distributed. "When the pores are ordered, you can get more of them into the same space," Wiesner explains.

The resulting materials were examined by electron microscopy, X-ray diffraction and a variety of other techniques, all of which confirmed a highly crystalline structure and a uniform porosity, the researchers reported.

The next step, Wiesner said, is to apply the CASH process to the creation of porous metals.

Co-authors of the Nature Materials paper are postdoctoral researcher Jinwoo Lee and graduate research assistants M. Christopher Orilall, Scott Warren and Marleen Kampeman.

####

About Cornell University

The strategic plan for research at Cornell can be summed up simply: Be the best at what we undertake to do. The research enterprise supports university research priorities: the New Life Sciences; cross-college collaborations; and enabling research areas--computing and information sciences, genomics, advanced materials, and nanoscience. We build on our strengths when creating programs, recruiting faculty, purchasing equipment, and supporting interdisciplinary programs. Cornell research is committed to knowledge transfer and engages in technology transfer and economic development activities that benefit local, regional, national, and international constituents.

For more information, please click here

Contacts:

Chronicle Online

312 College Ave.

Ithaca, NY 14850

607.255.4206

Bill Steele

Copyright © Cornell University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Discoveries

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Announcements

![]() Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Fuel Cells

![]() Deciphering local microstrain-induced optimization of asymmetric Fe single atomic sites for efficient oxygen reduction August 8th, 2025

Deciphering local microstrain-induced optimization of asymmetric Fe single atomic sites for efficient oxygen reduction August 8th, 2025

![]() Current and Future Developments in Nanomaterials and Carbon Nanotubes: Applications of Nanomaterials in Energy Storage and Electronics October 28th, 2022

Current and Future Developments in Nanomaterials and Carbon Nanotubes: Applications of Nanomaterials in Energy Storage and Electronics October 28th, 2022

Solar/Photovoltaic

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

![]() Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||