Home > Press > Materials scientists learn how to make liquid crystal shape-shift

|

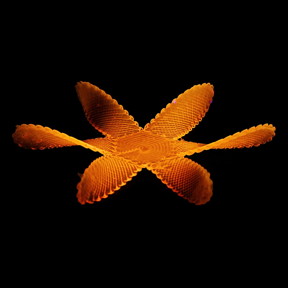

| Researchers also 3D-printed structures made of two layers of LCE with different properties and showed that this gave the material even more degrees of freedom to actuate. Researchers also printed lattice structures with the material, which could be used in medical applications. CREDIT University of California San Diego |

Abstract:

A new 3D-printing method will make it easier to manufacture and control the shape of soft robots, artificial muscles and wearable devices. Researchers at UC San Diego show that by controlling the printing temperature of liquid crystal elastomer, or LCE, they can control the material's degree of stiffness and ability to contract--also known as degree of actuation. What's more, they are able to change the stiffness of different areas in the same material by exposing it to heat.

Researchers 3D-printed structures made of two layers of LCE with different properties and showed that this gave the material even more degrees of freedom to actuate. Researchers also printed lattice structures with the material, which could be used in medical applications.

CREDIT

University of California San Diego

Materials scientists learn how to make liquid crystal shape-shift

San Diego, CA | Posted on September 25th, 2020As a proof of concept, the researchers 3D-printed in a single print, with a single ink, structures whose stiffness and actuation varies by orders of magnitude, from zero to 30 percent. For example, one area of the LCE structure can contract like muscles; and another can be flexible, like tendons. The breakthrough was possible because the team studied LCE closely to better understand its material properties.

The team, led by Shengqiang Cai, a professor in the Department of Mechanical and Aerospace Engineering at the UC San Diego Jacobs School of Engineering, details their work in the Sept. 25 issue of Science Advances.

Researchers were inspired to create this material with different degrees of actuation by examples in biology and nature. In addition to the combination of muscle and tendon, researchers took cues from the beak of the squid, which is extremely stiff at the tip but much softer and malleable where it is connected to the mouth of the squid.

"3D-printing is a great tool to make so many different things--and it's even better now that we can print structures that can contract and stiffen as desired under a certain stimuli, in this case, heat," said Zijun Wang, the paper's first author and a Ph.D. student in Cai's research group.

Understanding material properties

To understand how to tune the material properties of LCE, researchers first studied the material very closely. They determined that printed LCE filament is made of a shell and a core. While the shell cools off quickly after printing, becoming stiffer, the core cools more slowly, remaining more malleable.

As a result, researchers were able to determine how to vary several parameters in the printing process, especially temperature, to tune the mechanical properties of LCE. In a nutshell, the higher the printing temperature, the more flexible and malleable the material. While the preparation of the LCE ink takes a few days, the actual 3D print can be done in just 1 to 2 hours, depending on the geometry of the structure being printed.

"Based on the relationship between the properties of LCE filament and printing parameters, it's easy to construct structures with graded material properties," said Cai.

Varying temperature to 3D-printing structures

For example, researchers printed an LCE disk at 40 degrees C (104 F) and heated it up to 90 degrees C (194 F) in hot water. The disk deformed into a conical shape. But an LCE disk composed of areas that are printed at different temperatures (40, then 80 then 120 degrees Celsius, for example), deformed in a completely different shape when heated up.

Researchers also 3D-printed structures made of two layers of LCE with different properties and showed that this gave the material even more degrees of freedom to actuate. Researchers also printed lattice structures with the material, which could be used in medical applications.

Finally, as a proof of concept, the team 3D printed an LCE tube that they had tuned during 3D printing and showed that it could adhere to a rigid glass plate much longer when actuated at high temperatures, about 94 C (201 F), than a regular LCE tube with homogenous properties. This could lead to the manufacture of better robotic feet and grippers.

The actuation of the material could be activated not just in hot water but also by infusing LCE with heat-sensitive particles or particles that absorb light and convert it to heat--anything from black ink powder to graphene. Another mechanism would be to 3D print the structures with electric wires that generate heat embedded in LCE.

Next steps include finding a way to tune the material's properties more precisely and efficiently. Researchers also are working on modifying the ink so the printed structures can be self-repairable, reprogrammable, and recyclable.

####

For more information, please click here

Contacts:

Ioana Patringenaru

619-253-4474

@UCSanDiego

Copyright © University of California, San Diego

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Display technology/LEDs/SS Lighting/OLEDs

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() Light guide plate based on perovskite nanocomposites November 3rd, 2023

Light guide plate based on perovskite nanocomposites November 3rd, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

Robotics

![]() Femtosecond laser technique births "dancing microrobots": USTC's breakthrough in multi-material microfabrication August 11th, 2023

Femtosecond laser technique births "dancing microrobots": USTC's breakthrough in multi-material microfabrication August 11th, 2023

3D & 4D printing/Additive-manufacturing

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() 3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Videos/Movies

![]() New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

![]() Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Self-repairing Materials

![]() Self-driving microrobots December 10th, 2019

Self-driving microrobots December 10th, 2019

![]() Disruptive by Design: Nano Now February 1st, 2019

Disruptive by Design: Nano Now February 1st, 2019

![]() Fluid-inspired material self-heals before your eyes: Coating for metals rapidly heals over scratches and scrapes to prevent corrosion January 30th, 2019

Fluid-inspired material self-heals before your eyes: Coating for metals rapidly heals over scratches and scrapes to prevent corrosion January 30th, 2019

![]() Manufacturing microspheres: Technique mass-produces uniform, encapsulated particles for pharmaceuticals, many other uses October 6th, 2016

Manufacturing microspheres: Technique mass-produces uniform, encapsulated particles for pharmaceuticals, many other uses October 6th, 2016

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Printing/Lithography/Inkjet/Inks/Bio-printing/Dyes

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

![]() Disposable electronics on a simple sheet of paper October 7th, 2022

Disposable electronics on a simple sheet of paper October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||