Home > Press > Researchers mimic nature for fast, colorful 3D printing

|

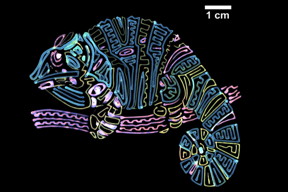

| Inspired by nature, Illinois researchers developed synthetic structure-based color materials – like those found in chameleon skin – for polymer inks used in 3D printing. Image courtesy Diao Research Group |

Abstract:

Brilliantly colored chameleons, butterflies, opals – and now some 3D-printed materials – reflect color by using nanoscale structures called photonic crystals.

Researchers mimic nature for fast, colorful 3D printing

Champaign, IL | Posted on June 10th, 2020A new study that demonstrates how a modified 3D-printing process provides a versatile approach to producing multiple colors from a single ink is published in the journal Science Advances.

Some of the most vibrant colors in nature come from a nanoscale phenomenon called structural coloration. When light rays reflect off these periodically placed structures located in the wings and skins of some animals and within some minerals, they constructively interfere with each other to amplify certain wavelengths and suppress others. When the structures are well ordered and small enough – about a thousand times smaller than a human hair, the researchers said – the rays produce a vivid burst of color.

“It is challenging to reproduce these vibrant colors in the polymers used to produce items like environmentally friendly paints and highly selective optical filters,” said study leader Ying Diao, a chemical and biomolecular engineering professor at the University of Illinois at Urbana-Champaign. “Precise control of polymer synthesis and processing is needed to form the incredibly thin, ordered layers that produce the structural color as we see in nature.”

The study reports that by carefully tuning the assembly process of uniquely structured bottlebrush-shaped polymers during 3D printing, it is possible to print photonic crystals with tunable layer thicknesses that reflect the visible light spectrum from a single ink.

The ink contains branched polymers with two bonded, chemically distinct segments. The researchers dissolve the material into a solution that mixes the polymer chains just before printing. After printing and as the solution dries, the components separate at a microscopic scale, forming nanoscale layers that exhibit different physical properties depending on the speed of assembly.

“The biggest challenge of the polymer synthesis is combining the precision required for the nanoscale assembly with the production of the large amounts of material necessary for the 3D-printing process,” said co-author Damien Guironnet, a professor of chemical and biomolecular engineering.

In the lab, the team uses a modified consumer 3D printer to fine-tune how fast a printing nozzle moves across a temperature-controlled surface. “Having control over the speed and temperature of ink deposition allows us to control the speed of assembly and the internal layer thickness at the nanoscale, which a normal 3D printer cannot do,” said Bijal Patel, a graduate student and lead author of the study. “That dictates how light will reflect off of them and, therefore, the color we see.”

The researchers said the color spectrum they have achieved with this method is limited, but they are working to make improvements by learning more about the kinetics behind how the multiple layers form in this process.

Additionally, the team is working on expanding the industrial relevance of the process, as the current method is not well suited for large-volume printing. “We are working with the Damien Guironnet, Charles Sing and Simon Rogers groups at the U. of I. to develop polymers and printing processes that are easier to control, bringing us closer to matching the vibrant colors produced by nature,” Diao said.

“This work highlights what is achievable as researchers begin to move past focusing on 3D printing as just a way to put down a bulk material in interesting shapes,” Patel said. “Here, we are directly changing the physical properties of the material at the point of printing and unlocking new behavior.”

Co-authors include graduate students Dylan J. Walsh and Justin Kwok, former undergraduate student Do Hoon Kim, and Guironnet, all of Illinois; and Argonne National Laboratory researcher Byeongdu Lee.

The National Science Foundation supported this research.

Diao also is affiliated with materials science and engineering and Beckman Institute for Advanced Science and Technology at Illinois

The paper “Tunable structural color of bottlebrush block copolymers through direct-write 3D printing from solution" is available from the U. of I. News Bureau.

Some of the technology discussed in this study was recently used by Patel and Diao to produce masks to combat the spread COVID-19.

####

For more information, please click here

Contacts:

LOIS YOKSOULIAN

PHYSICAL SCIENCES EDITOR

217-244-2788

Ying Diao

Bijal Patel

Copyright © University of Illinois at Urbana-Champaign

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Laboratories

![]() A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

![]() NRL discovers two-dimensional waveguides February 16th, 2024

NRL discovers two-dimensional waveguides February 16th, 2024

![]() Three-pronged approach discerns qualities of quantum spin liquids November 17th, 2023

Three-pronged approach discerns qualities of quantum spin liquids November 17th, 2023

3D & 4D printing/Additive-manufacturing

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

![]() 3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Videos/Movies

![]() New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

![]() Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Industrial

![]() Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

![]() Nanotubes: a promising solution for advanced rubber cables with 60% less conductive filler June 1st, 2022

Nanotubes: a promising solution for advanced rubber cables with 60% less conductive filler June 1st, 2022

![]() Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

![]() OCSiAl receives the green light for Luxembourg graphene nanotube facility project to power the next generation of electric vehicles in Europe March 4th, 2022

OCSiAl receives the green light for Luxembourg graphene nanotube facility project to power the next generation of electric vehicles in Europe March 4th, 2022

Printing/Lithography/Inkjet/Inks/Bio-printing/Dyes

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

![]() Disposable electronics on a simple sheet of paper October 7th, 2022

Disposable electronics on a simple sheet of paper October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||