Home > Press > CPI presents ultra‐flexible OTFT device array suitable for foldable AMOLED displays of the future

|

Abstract:

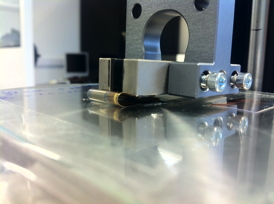

The Centre for Process Innovation (CPI) has developed novel backplane fabrication processes to allow the bending of Organic Thin Film Transistors (OTFT) arrays to small radii (1 mm) without a significant reduction in device performance. The work undertaken demonstrates progress towards optimum Organic Semiconductor (OSC)/OTFT processing and performance to enable their integration into ultra‐ flexible active matrix organic light emitting diode AMOLED backplanes. High performance OSC materials with charge mobility suitable for OLED driving were used in the tests on 50 micron thick PEN film.

CPI presents ultra‐flexible OTFT device array suitable for foldable AMOLED displays of the future

Wilton, UK | Posted on January 23rd, 2014In order to achieve the tight bend radius, the multiple interfaces present in the device stack were optimised to allow good adhesion under the strains experienced in the bending test. Using patterned OSC layers and additional passivation layer processing, display pixel size OTFTs were fabricated and these were repeatedly bent (up to 10,000 times) to a radius of 1 mm, which equates to a strain of 2.5%. Minimal change in the turn on voltage and on current were observed for the elongated cycle test.

This demonstration of bend resistance in high performance OTFT devices is part of ongoing work to integrate these materials into active matrix backplanes for AMOLED. It is expected that within 2014 the first plastic based display demonstrators will be completed using OTFT in project ROBOLED, which has received funding through the Technology Strategy Board.

A paper describing the bend testing and device processing work was delivered at the recent International Display Workshop (IDW) in Sapporo, Japan - see paper number OLED3‐2.

CPI is the UK's National Centre for Printable Electronics. Focused on the

development, scale‐up and commercialisation of printable electronics applications,

CPI is equipped with an extensive range of assets specifically chosen and developed

to allow clients to understand how their products and processes perform under pilot

manufacturing conditions.

####

About The Centre for Process Innovation

The Centre for Process Innovation is a UK‐based technology innovation centre and part of the High Value Manufacturing Catapult. We use applied knowledge in science and engineering combined with state of the art development facilities to enable our clients to develop, prove, prototype and scale up the next generation of products and processes.

Our open innovation model enables clients to develop products and prove processes with minimal risk. We provide assets and expertise so our customers can demonstrate the process before investing substantial amounts of money in capital equipment and training. New products and processes can be shown to be feasible; on paper, in the lab and in the plant before being manufactured at an industrial scale.

By utilising our proven assets and expertise companies can take their products and processes to market faster. There is no down time in production as all of the process development is completed offsite and our technology transfer and engineering teams can help companies to transfer the product or process into full scale production at speed.

For more information, please click here

Contacts:

Steven Bagshaw

Marketing Executive

The Centre for Process Innovation (CPI)

T: +44 (0)1740 625 700

M: +44 (0)777 813 6791

Copyright © The Centre for Process Innovation

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Display technology/LEDs/SS Lighting/OLEDs

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() Light guide plate based on perovskite nanocomposites November 3rd, 2023

Light guide plate based on perovskite nanocomposites November 3rd, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

Videos/Movies

![]() New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

![]() Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

![]() Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

![]() Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||