Home > Press > What makes superalloys super - hierarchical microstructure of a superalloy

|

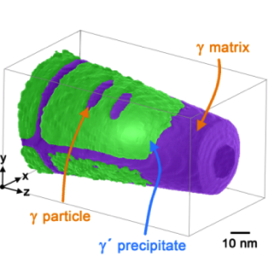

| The image shows the three-dimensional reconstruction of an atom probe measurement. The γ matrix (purple) can be seen surrounding the cuboidal γ’ precipitates (green). Only a few nanometre-sized γ platelets can be seen in the γ’ precipitates. Atom probe tomography allows a site specific analysis of the structure at the atomic scale and reveals the chemical composition in measurements of individual areas. Image: HZB |

Abstract:

Researchers have observed for the first time in detail how a hierarchical microstructure develops during heat treatment of a superalloy

What makes superalloys super - hierarchical microstructure of a superalloy

Berlin, Germany | Posted on January 14th, 2014Materials in high-performance turbines have to withstand not only powerful mechanical forces, they also have to maintain their chemical and mechanical properties almost up to their melting points. For this reason, turbine manufacturers have employed special nickel-based high-performance alloys for decades. New work from Helmholtz-Zentrum Berlin für Materialien and Energie (HZB) now shows in detail how new phases in a nickel-based alloy form and evolve, providing clues to how high-performance alloys could be improved. Doctoral student Florian Vogel and Dr. Nelia Wanderka from the HZB Institute of Applied Materials have elegantly combined two methods to accomplish this: transmission electron microscopy (TEM) and atom probe tomography (APT), which they carried out in collaboration with colleagues from the University of Münster.

They were interested in a phase separation phenomenon that has been known for around 50 years, but could neither be precisely observed nor understood until now: The microstructure of nickel-based alloys changes under controlled ageing or heat treatment and in the classical two-phase microstructure new phases are initially formed. Wanderka and Vogel were able to precisely observe the phase separation process on the atomic scale for the first time.

To do so, they simulated the ageing process of the alloy by heat treating it for different periods. They documented how the microstructure changed during the ageing of the alloy using micrographs from the transmission electron microscope. Whereas the classical two-phase microstructure consists of cuboid γ' precipitates embedded in a so called γ-matrix, during heat treatment, spherical γ particles initially form in the γ' precipitates of the alloy, then further coalesce into plates that finally split the γ' precipitates. The thermo-mechanical properties of these types of alloys depend largely on the stability of this γ/γ´ microstructure.

In order to determine the atomic constituents of the individual phases, but primarily to learn about the formation and make-up of the poorly understood γ particle, Vogel and Wanderka investigated the aged samples using atom probe tomography at the University of Münster. They succeeded in reconstructing the atomic lattice of the samples layer by layer and determining the composition of all phases, so that they could explain the chemical evolution of the γ particles.

"Until now, it was assumed that splitting of the γ' precipitates refines the microstructure during ageing, which would be beneficial for the alloy's stability under thermo-mechanical load. We were able to show that this is not correct. The microstructure indeed changes considerably, but it is not improved by the splitting however. We were actually able to correlate the best mechanical properties with the presence of spherical or plate-like γ particles and not with the later stages after splitting of the γ' precipitates has taken place", explains Florian Vogel. Nelia Wanderka adds: "If we want to improve the stability of the microstructure and thus the thermomechanical properties of the alloy, we need to be sure that the γ' precipitates are not split by the γ particles, but instead remain intact through appropriate heat treatment and composition of the alloy. Atom probe tomography helps us in understanding the role of the alloying elements in the formation and growth of the γ particles. From this, we can learn how to influence these processes."

####

For more information, please click here

Contacts:

Dr. Nelia Wanderka

49-308-062-42079

Florian Vogel

Tel (030) 8062 - 43217

Fax (030) 8062 - 43059

Dr. Antonia Rötger

Tel (030) 8062 - 43733

Fax (030) 8062 - 42998

Copyright © Helmholtz-Zentrum Berlin für Materialien und Energie

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Imaging

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

![]() Observation of left and right at nanoscale with optical force October 6th, 2023

Observation of left and right at nanoscale with optical force October 6th, 2023

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Tools

![]() Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

![]() The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

Automotive/Transportation

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Aerospace/Space

![]() Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

![]() Bridging light and electrons January 12th, 2024

Bridging light and electrons January 12th, 2024

![]() Manufacturing advances bring material back in vogue January 20th, 2023

Manufacturing advances bring material back in vogue January 20th, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||