Home > Press > Penn Produces Graphene Nanoribbons With Nanopores for Fast DNA Sequencing

|

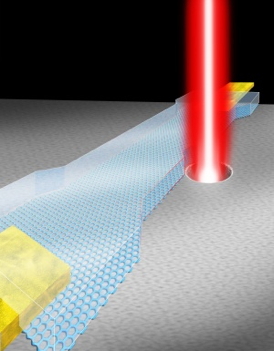

| An illustration of an electron beam drilling a notch-shaped nanopore in a graphene nanoribbon. |

Abstract:

The instructions for building all of the body's proteins are contained in a person's DNA, a string of chemicals that, if unwound and strung end to end, would form a sentence 3 billion letters long. Each person's sentence is unique, so learning how to read gene sequences as quickly and inexpensively as possible could pave the way to countless personalized medical applications.

Penn Produces Graphene Nanoribbons With Nanopores for Fast DNA Sequencing

Philadelphia, PA | Posted on November 18th, 2013Researchers at the University of Pennsylvania have now made an advance towards realizing a new sequencing technique based on threading that string through a tiny hole and using a nearby sensor to read each letter as it passes through.

Their DNA sensor is based on graphene, an atomically thin lattice of carbon. Earlier versions of the technique only made use of graphene's unbeatable thinness, but the Penn team's research shows how the Nobel Prize-winning material's unique electrical properties may be employed to make faster and more sensitive sequencing devices.

Critically, the team's latest study shows how to drill these nanopores without ruining graphene's electrical sensitivity, a risk posed by simply looking at the material through an electron microscope.

The team includes Marija Drndić, professor of physics in the School of Arts and Sciences, and members in her laboratory, including graduate student Matthew Puster and postdoctoral researchers Julio Rodríguez-Manzo and Adrian Balan.

Their research was published in the journal ACS Nano.

Drndić's group has previously demonstrated a series of advancements towards reading genes by passing them through a tiny hole, or nanopore. Their 2010 study involved drilling a hole in a sheet of graphene, then putting it in an ionic bath along with the strands of DNA to be detected. Because each of the four bases, the letters in DNA's alphabet, have a different size, a different number of ions would be expected to squeeze through along with each base as the strand passes through the pore. Researchers could then interpret the sequence of the DNA's bases by measuring the electrical signal of the ions. However, those current signals are weak, limiting the speed at which DNA could be sequenced.

Many research groups are now exploring multiple ways to improve the sensitivity and speed of the technique, including new materials and new ways of fashioning nanopores in them. Drndić's group has experimented with different membranes, as well as adding improved electronics to measure at faster speeds, but its latest study represents an entirely new way of generating an electrical signal unique to each base.

"Our latest attempt at improving the technique is a departure from our previous work, however," Drndić said. "We're now trying to measure current directly from the graphene, whereas before we measured ionic current in the solution as it goes through the pore."

The Penn team wanted to see if nanopores in graphene, the most conductive material known, would be capable of sensing the difference between bases directly. Instead of their different sizes, this method would rely on the bases altering the electric charge in the nearby material. In this case, the material would be a thin, wire-like ribbon of graphene. As each base passes through the pore, it would modulate the electrical current flowing through the ribbon. The changes in current would then be matched to their corresponding bases, allowing the researchers to decipher the sequence.

"The advantage," Balan said, "over the ionic method is that the current in the graphene ribbon is a thousand times higher. That means we can measure a thousand times faster. We wouldn't need to slow down the DNA to make an accurate measurement of each base."

After fabricating the graphene ribbons on a silicon nitride membrane and attaching metal contacts, the researchers wired them to measure their resistance and then put them in a transmission electron microscope, or TEM. This type of microscope uses a broad beam of electrons to produce images with nanoscale resolution by measuring the electrons as they pass through the sample, but it can also be used like a drill by focusing the beam.

The researchers had used a TEM to drill nanopores in sheets of graphene for their earlier sequencing experiments but encountered an unexpected challenge this time. When they put their ribbons in the TEM, they found resistances significantly increased, limiting sensitivity.

"Just looking at the graphene ribbons with the TEM caused them to degrade," Drndić said. "The wide beam we use for imaging was damaging them by introducing defects in the pattern of carbon atoms. It was almost not graphene any more."

"It didn't matter in our earlier experiments," Puster said, "since we were just using the graphene for its thinness and mechanical properties. We were creating these defects and raising the resistance, but we didn't realize it because we weren't measuring the graphene's electrical properties."

But with graphene's ultra-low resistance key to their proposed sequencing device, the team was presented with a quandary; they needed to poke a hole in a precise spot on a ribbon 10,000 times thinner than a human hair while effectively blindfolded.

"This was a real roadblock," Drndić said. "How were we going to drill these pores when just looking at the ribbon kills the device?"

The team's solution was to use a different imaging mode in the TEM, which produced a rough scan rather than high-definition picture.

"Instead of opening up the beam valve and flooding the ribbon with electrons," Rodríguez-Manzo said, "we use a scanning mode that just takes one snapshot. By taking the fuzziest picture that still tells us where the edge of the ribbon is, we limit the amount of electrons that hit it."

"The image we get back is very pixelated," Puster said. "But then we just need to pick the pixel where we want to put the pore or notch."

The team simultaneously measured the ribbons' resistances as they took these snapshots, clearly showing that they remained undamaged throughout the process. They also simulated the presence of a strand of DNA by using an electric field to test that the device would be sensitive enough to conduct DNA experiments with.

"I think this may solve problems for a lot of different nanosensors," Drndić said. "Whether they're made of graphene, nanowires, carbon nanotubes or other nanostructures, this will help keep them in working order while in a TEM. The main trick here is to drill the nanopore with as little imaging as possible, just taking a quick peek out from under the blindfold."

Their research was supported by the National Science Foundation and the National Institutes of Health.

####

For more information, please click here

Contacts:

Evan Lerner

215-573-6604

Copyright © University of Pennsylvania

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Graphene/ Graphite

![]() NRL discovers two-dimensional waveguides February 16th, 2024

NRL discovers two-dimensional waveguides February 16th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Nanomedicine

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

![]() Researchers develop artificial building blocks of life March 8th, 2024

Researchers develop artificial building blocks of life March 8th, 2024

Sensors

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||