Home > Press > Graphene with aroma: New production method broadens the perspectives for an improved use of the "magic material" - many different forms are possible

|

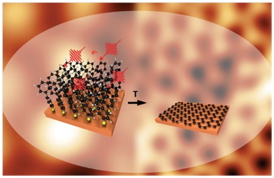

| The cover picture of the scientific journal "Advanced Materials" gives a schematic representation of the conversion of the monolayer of the complex molecule biphenyl thiol in the two-dimensional graphene crystal by electron irradiation and thermal treatment. Fig.: Advanced Materials 25 (2013). Copyright Wiley-VCH Verlag GmbH & Co. KGaA. Reproduced with permission. |

Abstract:

Graphene, a crystal composed of only one layer of carbon atoms arranged in a regular hexagon, is regarded as a material which is believed to be capable of performing miracles, in particular in the fields of electronics, sensor technology and display technology, but also in metrology. Only four years after the first successful preparation of graphene, its discoverers Geim and Novoselov were therefore awarded a Nobel Prize. As the original preparation method (flaking of single atomic layers of graphite) does not offer a good perspective for broad technological use, many groups of researchers are concentrating very strongly on the development of alternative manufacturing procedures. A completely new and very flexible variant has now been developed by the group of Andrey Turchanin from the University of Bielefeld in cooperation with the University of Ulm and three departments of the Physikalisch-Technische Bundesanstalt (PTB) and this has been published in the scientific journal "Advanced Materials".

Graphene with aroma: New production method broadens the perspectives for an improved use of the "magic material" - many different forms are possible

Bielefeld, Germany | Posted on October 2nd, 2013 In contrast to the conventional methods where graphene is manufactured, for example, by precipitation of carbon atoms from the gas phase or by thermal graphitization of silicon carbide, the scientists selected aromatic molecules as a starting point in this work. As substrates, both copper single-crystals and inexpensive polycrystalline copper foils were used. By irradiation with low-energy electrons and subsequent thermal annealing, it was then possible to convert a self-organized single-layer of the molecule biphenyl thiol, which had precipitated on the copper surface, into graphene.

To investigate the chemical and physical properties of the graphene manufactured in this way, different characterization methods from Ulm and Bielefeld universities and from PTB were applied, for example, scanning tunnelling microscopy, transmission electron microscopy, Raman spectroscopy as well as electric transport measurements at low temperatures and high magnetic fields. All these measurements confirm that graphene of excellent crystalline and electronic quality had actually been manufactured from the aromatic molecule. The flexibility of the electron irradiation, which is possible both over large areas and also with excellent spatial resolution at small, well-defined places, now allows graphene structures of basically any form to be manufactured, e.g. quantum dots, nanoribbons or other nano-geometries with specific functionality. The selection of the temperature in the thermal conversion step also allows the degree of crystallinity and the characteristics of the graphene depending on it to be adjusted.

Additional advantages result from the versatility of the method of self-organized coating. It can be performed with different aromatic molecules which could, for example, also contain doping atoms for electronic doping of the final product. Applied in multiple layers, so-called bi-layer or multi-layer graphene could be manufactured, whose changed electronic band structure expands the potential applications of single-layer graphene. Likewise, other substrates than the copper used here (for example other metals, semiconductors, isolators) can be used. In addition, it should also be possible to manufacture graphene on any three-dimensional surfaces, as molecular self-organization also takes place on curved surfaces. The new manufacturing method broadens the perspectives for an improved use of the "magic material" in such an impressive way that the respective publication was emphasized on the cover sheet of the August issue of the scientific journal "Advanced Materials".

####

For more information, please click here

Contacts:

Franz Josef Ahlers

PTB Department 2.6 Electric Quantum Metrology

49-531-592-2600

PD Dr. Andrey Turchanin

University of Bielefeld

Faculty of Physics

Physics of Super-molecular Systems and Surfaces

Bielefeld Institute for Biophysics and Nanoscience (BINAS)

Universitätsstr. 25

33615 Bielefeld

phone: +49(521) 106-5376

Copyright © Physikalisch-Technische Bundesanstalt (PTB)

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Imaging

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Graphene/ Graphite

![]() NRL discovers two-dimensional waveguides February 16th, 2024

NRL discovers two-dimensional waveguides February 16th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Tools

![]() Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

![]() The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

Quantum Dots/Rods

![]() A new kind of magnetism November 17th, 2023

A new kind of magnetism November 17th, 2023

![]() IOP Publishing celebrates World Quantum Day with the announcement of a special quantum collection and the winners of two prestigious quantum awards April 14th, 2023

IOP Publishing celebrates World Quantum Day with the announcement of a special quantum collection and the winners of two prestigious quantum awards April 14th, 2023

![]() Qubits on strong stimulants: Researchers find ways to improve the storage time of quantum information in a spin rich material January 27th, 2023

Qubits on strong stimulants: Researchers find ways to improve the storage time of quantum information in a spin rich material January 27th, 2023

![]() NIST’s grid of quantum islands could reveal secrets for powerful technologies November 18th, 2022

NIST’s grid of quantum islands could reveal secrets for powerful technologies November 18th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||