Home > Press > New microfluidic method expands toolbox for nanoparticle manipulation

|

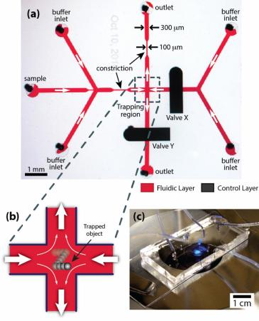

| The 2-D microfluidic trap. a) Optical micrograph of a microfluidic manipulation device. Single particles are confined at a predetermined location within the junction of two perpendicular microchannels (trapping region). Two on-chip membrane valves (black) positioned above one inlet channel and one outlet channel are used as metering valves to control the relative flow rates through the opposing channels (red), thereby manipulating and trapping particles at the microchannel junction. b) Schematic of 2-D particle trapping. Two opposing laminar streams meet at the intersection of two perpendicular microchannels, creating a well-defined flow field containing a stagnation point where an object is trapped. c) The microfluidic manipulation device consists of a glass coverslip and a PDMS slab containing the microchannels and valves. Reprinted with permission 2013 American Chemical Society. |

Abstract:

Researchers at the University of Illinois at Urbana-Champaign have developed a new flow-based method for manipulating and confining single particles in free solution, a process that will help address current challenges faced by nanoscientists and engineers.

New microfluidic method expands toolbox for nanoparticle manipulation

Urbana, IL | Posted on June 5th, 2013"This method is a first-of-its-kind tool for manipulation and trapping of small nanoparticles in solution," explained Charles M. Schroeder, an assistant professor in the Department of Chemical and Biomolecular Engineering at Illinois. "Using fluid flow in a microfluidic device means that electrical, magnetic, optical, or acoustic force fields are not necessary."

The new method and the research to develop it were published in the May 2013 issue of Nano Letters, in a paper, "Manipulation and Confinement of Single Particles Using Fluid Flow," authored by Schroeder and postdoctoral researcher Melikhan Tanyeri. The research was performed in Schroeder's laboratory located in Roger Adams Lab on the Illinois campus.

Today, fine-scale manipulation of small particles remains a major challenge in the field. Current methods for particle trapping mainly rely on electrokinetic, magnetic, or optical force fields, which may not be compatible with biomolecules or biological systems.

Together, Schroeder and Tanyeri developed a "microfluidic trap" capable of 2-D particle manipulation using the sole action of fluid flow.

Schroeder and researchers demonstrate several unique features of the microfluidic trap, including 2-D manipulation of particles as small as 500 nanometers in size in water, with a positioning precision of only about 180 nanometers, trapping of particles as small as 100 nanometers, and active control over the solution conditions of a trapped particle. All of this is achieved with a simple PDMS-based microfluidic device without the need for complex instrumentation for optical trapping or electric field generation.

"The microfluidic trap provides a fundamentally new method for the trapping and analysis of single particles or single molecules, complementing existing techniques," Schroeder said. "Our new technology will find pervasive use in interdisciplinary fields such as nanoscience, materials science, complex fluids, soft materials, microbiology, and molecular biology."

Schroeder and Tanyeri said they now have the ability to trap a range of particle sizes.

"Unlike existing methods such as conventional optical or magnetic traps, the microfluidic trap will allow for trapping of tiny nanoparticles, less than 30 nanometers in free solution," Tanyeri said.

With the precise positional control of single nanoparticles in free solution, scientists will be able to explore new technologies, from molecular engineering to bottom-up assembly of nanostructures.

"Fluidic-directed assembly may further enhance existing lithographic, self-assembly, and surface patterning approaches for fabricating nanoscale functional materials and devices," Tanyeri said. "This is a key technological advance that will help to address problems in nanoscience and engineering that are inaccessible to current methods, such as directed assembly and patterning of soft materials."

####

For more information, please click here

Contacts:

Charles M. Schroeder

217-333-3906

Writer:

Sarah Williams

assistant director of communications

Department of Chemical and Biomolecular Engineering

217/244-0541

Copyright © University of Illinois College of Engineering

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Microfluidics/Nanofluidics

![]() Implantable device shrinks pancreatic tumors: Taming pancreatic cancer with intratumoral immunotherapy April 14th, 2023

Implantable device shrinks pancreatic tumors: Taming pancreatic cancer with intratumoral immunotherapy April 14th, 2023

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

![]() Oregon State University research pushes closer to new therapy for pancreatic cancer May 6th, 2022

Oregon State University research pushes closer to new therapy for pancreatic cancer May 6th, 2022

Self Assembly

![]() Liquid crystal templated chiral nanomaterials October 14th, 2022

Liquid crystal templated chiral nanomaterials October 14th, 2022

![]() Nanoclusters self-organize into centimeter-scale hierarchical assemblies April 22nd, 2022

Nanoclusters self-organize into centimeter-scale hierarchical assemblies April 22nd, 2022

![]() Atom by atom: building precise smaller nanoparticles with templates March 4th, 2022

Atom by atom: building precise smaller nanoparticles with templates March 4th, 2022

![]() Nanostructures get complex with electron equivalents: Nanoparticles of two different sizes break away from symmetrical designs January 14th, 2022

Nanostructures get complex with electron equivalents: Nanoparticles of two different sizes break away from symmetrical designs January 14th, 2022

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Printing/Lithography/Inkjet/Inks/Bio-printing/Dyes

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

![]() Disposable electronics on a simple sheet of paper October 7th, 2022

Disposable electronics on a simple sheet of paper October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||