Home > Press > Precitech Introduces the Nanoform X Ultra Precision Machining System

|

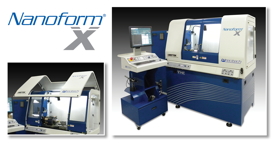

| Precitech’s Nanoform® X Ultra Precision Machining System is designed to increase productivity and ease of use in diamond turning, milling and grinding of optical lenses, mold inserts, mirrors, and precision mechanical components. |

Abstract:

Precitech, a global manufacturer of innovative ultra precision machining solutions, has introduced the Nanoform® X Multi-Axis Ultra Precision Machining System.

Precitech Introduces the Nanoform X Ultra Precision Machining System

Keene, NH | Posted on May 13th, 2013The Nanoform X is designed to increase productivity and ease of use in the diamond turning, milling, and grinding of optical lenses, mold inserts, mirrors, and precision mechanical components. The machine can be configured from two to four axes to produce spherical, aspherical, and freeform surfaces of up to 440mm in diameter.

"We listened to our customers and added a number of features that improve productivity and ease of use. The design challenge was to ensure that these new features would not impact the core accuracy of the machine," notes Jeff Roblee, Vice President of Technology for Precitech.

"With the Nanoform X, we were able to improve machine performance, particularly its vibration and temperature sensitivity. We enlisted the assistance of TMC, a world leader in precision vibration control, to help with the design of the vibration isolation system. Both Precitech and TMC are business units of AMETEK Ultra Precision Technologies."

Nanoform X incorporates features that reduce machine downtime by minimizing the time required to perform non-value-added activities, such as machine and tool setup, maintenance, and cleanup. The most significant of these design changes were put in place to reduce cleanup time and better contain swarf (the waste and debris that results from metalworking operations).

Among the most obvious design improvements is a fully opening upper enclosure. This feature provides the operator with unprecedented access to the inner surfaces of the machine. In addition, the sloped sides on the upper enclosure and the stainless steel tray over the machine's granite base contribute significantly to improved swarf containment and reduced cleanup time.

Other non-value added activities that are greatly reduced with the Nanoform X are machine and tool setup times.These are reduced with Precitech's new productivity tools and the high-speed HS-150 Work Holding Spindle, which are both standard features on the X.

Precitech also lowered the work envelope by 11 cm (4 in.) and further improved operator ease of use by enhancing the Nanoform X's control console.

The ergonomic control console, in particular, offers a number of user-friendly features, including a jog wheel and standard directional control of the axes, programmable soft keys, and convenient shelving for storing many of the tools required for ultra precision machining.

####

About Precitech

Precitech is a global manufacturer of innovative ultra precision machining solutions. It designs and manufactures precision machining systems for turning, milling, and grinding. These systems produce rotationally symmetric, asymmetric, freeform and sculpted geometries, achieving form tolerances in the sub-micron range and nanometer surface finishes when equipped with diamond tooling.

Precitech is a unit of AMETEK Ultra Precision Technologies, a division of

AMETEK, Inc, a leading global manufacturer of electronic instruments and

electromechanical devices, with annual sales of more than $3.3 billion.

For more information, please click here

Contacts:

Precitech

44 Blackbrook Road

Keene, NH 03431, USA

Tel: (603) 357-2511

Fax: (603) 358-6174

Copyright © Precitech

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Tools

![]() Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

![]() The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

Photonics/Optics/Lasers

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Optically trapped quantum droplets of light can bind together to form macroscopic complexes March 8th, 2024

Optically trapped quantum droplets of light can bind together to form macroscopic complexes March 8th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||