Home > Press > Peratech designs the QTC Ultra Sensor - an ultra-sensitive touch sensor for domestic, commercial and industrial use: Pressure sensor so sensitive that it can be operated through glass or steel sheet

|

Abstract:

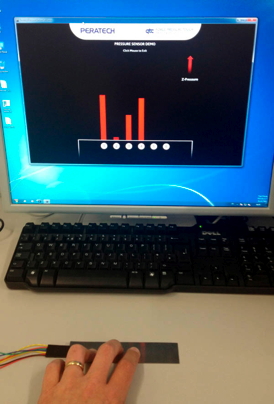

Peratech, the innovators in touch technology, has developed an ultra-sensitive sensor using its award winning QTC™ technology. Quantum Tunnelling Composite material changes its resistance when pressure is applied, enabling it to be used to make pressure sensors that can respond to light touches even through steel or glass.

Peratech designs the QTC Ultra Sensor - an ultra-sensitive touch sensor for domestic, commercial and industrial use: Pressure sensor so sensitive that it can be operated through glass or steel sheet

Richmond, UK | Posted on May 13th, 2013"We have developed a sensor design that is so sensitive that it can be mounted behind a 0.1mm stainless steel or 0.5mm glass sheet and still detect the pressure of a finger on the top of the sheet," said David Lussey, CTO of Peratech. "The QTC Ultra Sensor™ only takes a deflection of a micron or so for QTC to sense the touch through the sheet."

Fitting conventional switches to products always introduces a point of possible failure either within the switch or the fitting of the switch. QTC Ultra Sensor solve this as it can either be fitted as a small piece of QTC sheeting or screen printed on the back of the steel plate as required by the product designer. The design works equally well with other materials such as plastics, glass or wood provided that there is enough flex to activate the QTC switch. It can even be used behind translucent materials to create secret till lit buttons. QTC solutions are thinner, smaller, more discrete, less expensive and ultra-reliable as there is no air gap and no moving parts making them ideal for domestic, commercial and industrial equipment.

Peratech is not selling the QTC Ultra Sensor as it uses the highly successful, Intellectual Property business model whereby it licenses the use of its QTC technology solutions to customers. "QTC Ultra Sensors have already attracted interest from white goods and automotive manufacturers," explained David Lussey. "By taking a license they can deploy QTC Ultra Sensors throughout their product range to give sleek, discrete and ultra-reliable touch controls."

QTC material has nano-sized particles of conductive material evenly distributed in a non-conductive polymer. When a force is applied the particles move close enough for electrons to flow between the particles using an effect called Quantum Tunnelling. QTC technology has been used to make the world's thinnest switch at only a few microns thick and can be made into any shape required or printed with whatever level of responsiveness to pressure that is needed.

####

About Peratech Limited

Founded in 1996, Peratech is a privately held company with 25 employees based in Richmond, North Yorkshire. It commercialised its QTC technology at the beginning of 2006 and is currently working with a number of key technology clients who are implementing QTC sensing technology within their own products. Its business is essentially the IP licensing model that has been proven to be rapidly scalable and highly profitable for the likes of ARM and many others. The company is profitable, with 100% of sales being to overseas' customers making it an excellent example of British innovation bringing in global revenue. Peratech is a rare example of a university spin-in with a close working relationship with the University of Durham who are researching into the properties of Quantum Tunnelling Composites. QTC technology is protected by numerous worldwide patents and has a wide range of applications. From robotics to automotive and from touch screens to consumer electrical products, the product has sales worth millions of pounds to companies around the world. Peratech's multi-award winning QTC technology received the Queen's Award for Enterprise in Innovation in November 2012.

For more information, please click here

Contacts:

Peratech Limited

Old Repeater Station

Brompton-on-Swale, North Yorkshire, DL10 7JH United Kingdom

Tel: +44 (0) 8700 727272

Fax: +44 (0) 8700 727273

www.peratech.com

Nigel Robson

Vortex PR

Island House, Forest Road

Forest, Guernsey, GY8 0AB United Kingdom

Tel: +44 (0) 1481 233080

Copyright © Peratech

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Videos/Movies

![]() New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

![]() Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

![]() Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

![]() Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Products

![]() Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

![]() Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

![]() Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

![]() Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Sensors

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Industrial

![]() Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

![]() Nanotubes: a promising solution for advanced rubber cables with 60% less conductive filler June 1st, 2022

Nanotubes: a promising solution for advanced rubber cables with 60% less conductive filler June 1st, 2022

![]() Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

![]() OCSiAl receives the green light for Luxembourg graphene nanotube facility project to power the next generation of electric vehicles in Europe March 4th, 2022

OCSiAl receives the green light for Luxembourg graphene nanotube facility project to power the next generation of electric vehicles in Europe March 4th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||