Home > Press > Materials scientists make additive-free battery electrodes with nanoparticles

|

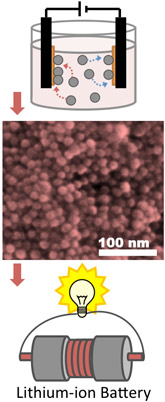

| Provided/Richard Robinson Nanoparticle battery electrodes deposited through electrophoretic deposition could lead to lighter and more efficient batteries. At top is a schematic of the EPD process. The middle is an electron microscope image of the nanoparticle electrode. |

Abstract:

Materials scientists have developed a simple, robust way to fabricate carbon-free and polymer-free, lightweight colloidal films for lithium-ion battery electrodes, which could greatly improve battery performance.

Materials scientists make additive-free battery electrodes with nanoparticles

Ithaca, NY | Posted on November 1st, 2012By Anne Ju

By developing a method for additive-free electrodes that maintain high conductivity, the researchers have opened new possibilities for reducing the weight and volume of batteries, while also creating a template system for studying the physics of nanoparticle electrodes.

The work, led by Richard Robinson, assistant professor of materials science and engineering, and graduate student Don-Hyung Ha, is featured in the Oct. 10 issue of Nano Letters (Vol. 12, No. 10).

Nanoparticles have been extensively investigated as an active cathode and anode in lithium-ion batteries -- common components of electronic devices -- because they can enhance the batteries' electrochemical properties.

To use colloidal nanoparticles for the electrodes, it had been necessary to combine them with carbon-based conductive materials for enhancing charge transport, as well as polymeric binders to stick the particles together and to the electrode substrate, Robinson said. This process added extra weight to the battery and made it difficult to model the movement of Li-ions and electrons through the mixture.

The critical processing technique Robinson and colleagues used was electrophoretic deposition, which binds the metal nanoparticles to the surface of the electrode substrate to each other in an assembly, creating strong electrical contacts between the particles and current collector.

The process results in a significant improvement in battery electrode assembly that cannot be replicated by conventional methods. Once attached, the particles are no longer soluble and are mechanically robust. In fact, this processing creates a film that has superior mechanical stability when compared to films fabricated by conventional battery-making methods with binders, Robinson said.

This research has led to the first cobalt-oxide nanoparticle-film battery electrode made without using binders and carbon black additives, and they show high gravimetric and volumetric capacities, even after 50 cycles.

The work was supported by the Energy Materials Center at Cornell funded by the U.S. Department of Energy, Office of Science, Office of Basic Energy Science; the Cornell Center for Materials Research with funding from the National Science Foundation; and by the King Abdullah University of Science and Technology center at Cornell.

####

For more information, please click here

Contacts:

Media Contact:

John Carberry

(607) 255-5553

Cornell Chronicle:

Anne Ju

(607) 255-9735

Copyright © Cornell University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Energy

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

Battery Technology/Capacitors/Generators/Piezoelectrics/Thermoelectrics/Energy storage

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

Research partnerships

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() 'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||