Home > Press > Microbullets reveal material strengths: Rice, MIT research could help maximize strength of body armor for soldiers, aerospace materials

|

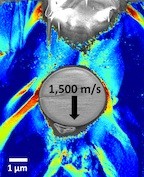

| An electron microscope image shows the effects of a silica sphere less than a 10th the width of a human hair on a block copolymer. The sphere was fired at the copolymer at 1,500 meters per second to study the effect of such impacts on advanced materials being developed to protect soldiers, aircraft and spacecraft. Compressed layers of the copolymer appear in red and orange. (Credit: Thomas Lab/Rice University) |

Abstract:

In the macro world, it's easy to see what happens when a bullet hits an object. But what happens at the nanoscale with very tiny bullets?

Microbullets reveal material strengths: Rice, MIT research could help maximize strength of body armor for soldiers, aerospace materials

Houston, TX | Posted on October 30th, 2012A Rice University lab, in collaboration with researchers at the Massachusetts Institute of Technology and its Institute for Soldier Nanotechnologies, decided to find out by creating the nanoscale target materials, the microscale ammo and even the method for firing them.

In the process, they gathered a surprising amount of information about how materials called block copolymers dissipate the strain of sudden impact.

The goal of researchers is to find novel ways to make materials more impervious to deformation or failure for stronger and lighter body armor, jet engine turbine blades for aircraft, and for cladding to protect spacecraft and satellites from micrometeorites and space junk. Their work was detailed in the online journal Nature Communications.

The group was led by Rice materials scientist Ned Thomas, the William and Stephanie Sick Dean of Rice's George R. Brown School of Engineering, and Rice research scientist and lead author Jae-Hwang Lee.

The researchers were inspired by their observations in macroscopic ballistic tests in which a complex multiblock copolymer polyurethane material showed the ability to not only stop a 9 mm bullet but also seal the entryway behind it.

"The polymer has actually arrested the bullet and sealed it," Thomas said, holding a hockey puck-sized piece of clear plastic with three bullets firmly embedded. "There's no macroscopic damage; the material hasn't failed; it hasn't cracked. You can still see through it. This would be a great ballistic windshield material.

"We want to find out why this polyurethane works the way it does. Theoretically, no one understood why this particular kind of material - which has nanoscale features of glassy and rubbery domains - would be so good at dissipating energy," he said.

One problem, Thomas said, is that cutting the polymer to analyze it on the nanoscale "would take days." The researchers sought a model material that would react similarly at the nanoscale and could be analyzed much faster. They found one in a polystyrene-polydimethylsiloxane diblock-copolymer. The material self-assembles into alternating 20-nanometer layers of glassy and rubbery polymers. Under a scanning electron microscope, it looks like corduroy; after the test, the disruption pattern from impact can be clearly seen.

The results showed several expected deformation mechanisms and the unexpected result that for sufficiently high velocities, the layered material melted into a homogeneous liquid that seemed to help arrest the projectile and, like the polymer, seal its entry path. The copolymer also behaved differently depending on where the spheres hit. The material showed the best ability to dissipate the energy of impact when spheres were fired perpendicular to the layers, Thomas said.

Testing their ideas took special equipment. The research team came up with a miniaturized test method, dubbed the laser-induced projectile impact test (LIPIT), that uses a laser pulse to fire glass spheres about 3 microns in diameter. The spheres sit on one side of a thin absorbing film facing the target. When a pulse hits the film, the energy causes it to vaporize and the spheres to fly off, hitting speeds between .5 and 5 kilometers per second. Since the kinetic energy scales with velocity squared, the factor of 10 in speed translates to a factor of 100 in impact energy, Thomas said.

Lee calculated the impact in real-world terms: The spheres strike their target 2,000 times faster than an apple falling one meter hits the ground, but with a million times less force. However, because the sphere's impact area is so concentrated, the impact energy is more than 760 times greater. That leaves a mark, he said.

The team tested their materials in two ways: horizontally, with the impact perpendicular to the micro grain, and vertically, straight into the layered edges. They found the horizontal material best at stopping projectiles, perhaps because the layers reflect part of the incident shock wave. Beyond the melt zone in front of the projectile, the layers showed the ability to deform without breaking, which led to improved energy absorption.

"After the impact we can go in and cross-section the structure and see how deep the bullet got, and see what happened to these nice parallel layers," Thomas said. "They tell the story of the evolution of penetration of the projectile and help us understand what mechanisms, at the nanoscale, may be taking place in order for this to be such a great, high-performance, lightweight protection material."

Thomas would like to extend LIPIT testing to other lightweight, nanostructured materials like boron nitride, carbon nanotube-reinforced composites and graphite and graphene-based materials. The ultimate goal, he said, is to accelerate the design of metamaterials with precise control of their nano- and microstructures for a variety of applications.

Co-authors of the paper are graduate students David Veysset, Jonathan Singer, Gagan Saini and Keith Nelson at MIT; Markus Retsch of MIT and the University of Bayreuth, Germany; and Tomas Pezeril of MIT and the Université du Maine, Le Mans, France.

The research was supported by the U.S. Army Research Office.

####

About Rice University

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation's top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,708 undergraduates and 2,374 graduate students, Rice's undergraduate student-to-faculty ratio is 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice has been ranked No. 1 for best quality of life multiple times by the Princeton Review and No. 2 for "best value" among private universities by Kiplinger's Personal Finance. To read "What they're saying about Rice," go to tinyurl.com/AboutRice.

Follow Rice News and Media Relations via Twitter @RiceUNews

For more information, please click here

Contacts:

David Ruth

713-348-6327

Mike Williams

713-348-6728

Copyright © Rice University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() Edwin “Ned” Thomas research summary:

Edwin “Ned” Thomas research summary:

![]() Institute for Soldier Nanotechnologies:

Institute for Soldier Nanotechnologies:

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Videos/Movies

![]() New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

![]() Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

![]() Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

![]() Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Military

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() New chip opens door to AI computing at light speed February 16th, 2024

New chip opens door to AI computing at light speed February 16th, 2024

Aerospace/Space

![]() Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

![]() Bridging light and electrons January 12th, 2024

Bridging light and electrons January 12th, 2024

![]() Manufacturing advances bring material back in vogue January 20th, 2023

Manufacturing advances bring material back in vogue January 20th, 2023

Research partnerships

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() 'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||