Home > Press > 'Nano machine shop' shapes nanowires, ultrathin films

|

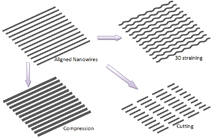

| This illustration depicts a new nano machine shop's ability to shape tiny wires, an advance that represents a possible future manufacturing method for applications ranging from high-speed electronics to solar cells. (Purdue University image/Gary Cheng) |

Abstract:

Laser Shock-Based Platform for Controllable Forming of Nanowires

Ji Li, Yiliang Liao, Sergey Suslov, and Gary J. Cheng*

Birck Nanotechnology Center and School of Industrial Engineering, Purdue University

One-dimensional nanomaterials have attracted a great deal of research interest in the past few decades due to their unique mechanical, electrical and optical properties. Changing the shape of nanowires (NWs) is both challenging and crucial to change the property and open wide functions of NWs, such as strain engineering, electronic transport, mechanical properties, band structure and quantum properties, etc. Here we report a scalable strategy to conduct cutting, bending and periodic straining of NWs by making use of laser shock pressure. Three-dimensional shaping of silver NWs is demonstrated, during which the Ag NWs exhibit very good ductility (strain-to-failure reaches 110%). Meanwhile, the high electrical conductivity of Ag NWs could retain well under controlled laser shock pressure. The microstructure observation indicates that the main deformation mechanism in Ag NWs under dynamic loading is formation of twinning and stacking fault, while dislocation motion and pile-up is less obvious. This method could be applied to semiconductor NWs as well.

'Nano machine shop' shapes nanowires, ultrathin films

West Lafayette, IN | Posted on August 29th, 2012A new "nano machine shop" that shapes nanowires and ultrathin films could represent a future manufacturing method for tiny structures with potentially revolutionary properties.

The structures might be tuned for applications ranging from high-speed electronics to solar cells and also may have greater strength and unusual traits such as ultrahigh magnetism and "plasmonic resonance," which could lead to improved optics, computers and electronics.

The researchers used their technique to stamp nano- and microgears; form tiny circular shapes out of a material called graphene, an ultrathin sheet of carbon that holds promise for advanced technologies; and change the shape of silver nanowires, said Gary Cheng, an associate professor of industrial engineering at Purdue University.

"We do this shaping at room temperature and atmospheric pressure, like a nano-machine shop," said Cheng, who is working with doctoral students Ji Li, Yiliang Liao, Ting-Fung Chung and Sergey Suslov and physics professor Yong P. Chen.

Graphene and nanowires - filaments 1,000 times thinner than a human hair - have numerous potential applications. However, technologies are needed to tailor them for specific uses. The new method, called laser shock-induced shaping, makes it possible to tune nanowires by altering electrical and optoelectrical properties that are critical for electronic components.

The researchers also have shown how laser shock-induced shaping can be used to change the properties of graphene, a step toward harnessing the material for electronic applications.

Findings were detailed in research papers published in the journal Nano Letters, and the work also was highlighted earlier this month in the News and Views section of the journal Nature Photonics. (The article is available at www.nature.com/nphoton/journal/v6/n8/full/nphoton.2012.186.html)

The technique works by using a multilayered sandwich structure that has a tiny mold at the bottom. Nanowires were situated directly above the mold, and other materials were layered between the nanowires and a glass cover sheet. Exposing this layered "forming unit" to an ultra-fast pulsing laser causes one of the layers to burn up, generating a downward pressure that forces the nanowires into the mold and changes their shape.

"The process could be scaled up for an industrial roll-to-roll manufacturing process by changing laser beam size and scanning speed," Cheng said. "The laser shock-induced shaping approach is fast and low-cost."

Part of the research, funded by the National Science Foundation, was carried out in a specialized clean room at the Birck Nanotechnology Center in Purdue's Discovery Park.

####

For more information, please click here

Contacts:

Writer:

Emil Venere

765-494-4709

Source:

Gary J. Cheng

765-494-5436

Copyright © Princeton University, Engineering School

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Thin films

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Graphene/ Graphite

![]() NRL discovers two-dimensional waveguides February 16th, 2024

NRL discovers two-dimensional waveguides February 16th, 2024

NEMS

![]() IEDM - CEA-Leti Will Present 11 Papers and Host Workshop on Disruptive Technologies for Data Management November 7th, 2018

IEDM - CEA-Leti Will Present 11 Papers and Host Workshop on Disruptive Technologies for Data Management November 7th, 2018

![]() UT engineers develop first method for controlling nanomotors: Breakthrough for nanotechnology as UT engineers develop first method for switching the mechanical motion of nanomotors September 21st, 2018

UT engineers develop first method for controlling nanomotors: Breakthrough for nanotechnology as UT engineers develop first method for switching the mechanical motion of nanomotors September 21st, 2018

![]() Nano-kirigami: 'Paper-cut' provides model for 3D intelligent nanofabrication July 13th, 2018

Nano-kirigami: 'Paper-cut' provides model for 3D intelligent nanofabrication July 13th, 2018

![]() One string to rule them all April 17th, 2018

One string to rule them all April 17th, 2018

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Nanoelectronics

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

![]() Reduced power consumption in semiconductor devices September 23rd, 2022

Reduced power consumption in semiconductor devices September 23rd, 2022

![]() Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Energy

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

Photonics/Optics/Lasers

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Optically trapped quantum droplets of light can bind together to form macroscopic complexes March 8th, 2024

Optically trapped quantum droplets of light can bind together to form macroscopic complexes March 8th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Solar/Photovoltaic

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||