Home > Press > Functional coatings from the plasma nozzle

|

Abstract:

These coatings offer protection against rust, scratches and moisture and improve adhesion: Surfaces with a nano coating. A new plasma process enables these coatings to be applied more easily and cost-efficiently - on an industrial scale.

Functional coatings from the plasma nozzle

Munich, Germany | Posted on May 18th, 2012When manufacturing products, the coating technology is a key innovation driver for almost all areas of daily life - for example, for making scratch-proof displays for smart phones or anti-bacterial surfaces in refrigerators. Other coatings protect components from corrosion or aging, for example in a solar cell module or a car engine, without the end user noticing their existence. In industry today, wet chemical processes or vacuum plasma processes are primarily used for coating applications. Both have drawbacks. Vacuum units are expensive, limited to smaller components and applying a coating takes a relatively long time. Wet chemical processes often involve high resource and energy consumption with the corresponding environmental damage and can also cause difficulties in the handling of material combinations for lightweight construction such as plastics/ metals or aluminum/steel.

"There has to be another way", thought Dr. Jörg Ihde and Dr. Uwe Lommatzsch from the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Bremen. Together with Plasmatreat GmbH, the IFAM team developed a new kind of plasma coating process that works at ambient pressure, that is to say, in an open atmosphere. "And that poses a major challenge", explains Jörg Ihde. "Because the pressure is more than 10,000 times higher and the absence of a vacuum reactor, we had to stop unwanted particles from forming and embedding in the coating. That was the key to developing robust and efficient industrial processes using the new plasma system.

One nozzle - various functional coatings

The central element is a plasma nozzle. The nozzle is no bigger than a typical spray can. Yet it contains a highly complex coating system. "In the nozzle, an electrical discharge generates small flashes - a plasma that is expelled from the nozzle in the form of a jet. We systematically feed into the nozzle outlet those materials that are excited and fragmented in the plasma and then deposited out of the plasma jet as a functional nano-layer onto the surface", explains Uwe Lommatzsch. "We achieve extremely high deposition rates, enabling fast and cost-effective production processes to be realized."

The use of a nozzle allows the coating to be applied very precisely and only where it is needed, thus conserving resources. "We can control the processes so that the same nozzle can be used to apply coatings with various functionalities, for corrosion protection or for increasing or reducing adhesion, for instance", adds Jörg Ihde. Only very small amounts of coating material are required and practically all materials and material combinations can be coated. The process offers, in addition to the coating qualities and functionalities, even more benefits: it can be easily integrated into an inline production process, requires little space and is easy to automate, meaning it can be controlled via a robot. Yet another advantage: low investment costs and easy on the environment. The positive characteristics benefit industrial production: depositing an adhesion-promoting coating on a car window edge before gluing it in, to replace environmentally damaging chemicals or as a substitute for thick protective paint on printed circuit boards, which improves heat dissipation and hence prolongs service life. The process is already employed in the automotive industry and the energy sector to provide protection against corrosion and aging.

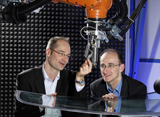

One of this year‘s Joseph-von-Fraunhofer prizes was awarded to Dr. Jörg Ihde and Dr. Uwe Lommatzsch for their development of a resource-efficient process for the high-rate deposition of functional nano-layers.

####

For more information, please click here

Contacts:

Joerg Ihde

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Wiener Str. 12

28359 Bremen, Germany

Phone +49 421 2246-427

Fax +49 421 2246-300

Copyright © Fraunhofer-Gesellschaft

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() Research News Special issue awards [ PDF 0,74 MB ]:

Research News Special issue awards [ PDF 0,74 MB ]:

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Energy

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

Industrial

![]() Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

![]() Nanotubes: a promising solution for advanced rubber cables with 60% less conductive filler June 1st, 2022

Nanotubes: a promising solution for advanced rubber cables with 60% less conductive filler June 1st, 2022

![]() Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

![]() OCSiAl receives the green light for Luxembourg graphene nanotube facility project to power the next generation of electric vehicles in Europe March 4th, 2022

OCSiAl receives the green light for Luxembourg graphene nanotube facility project to power the next generation of electric vehicles in Europe March 4th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||