Home > Press > Carbon nanotubes best for 3D electronics

|

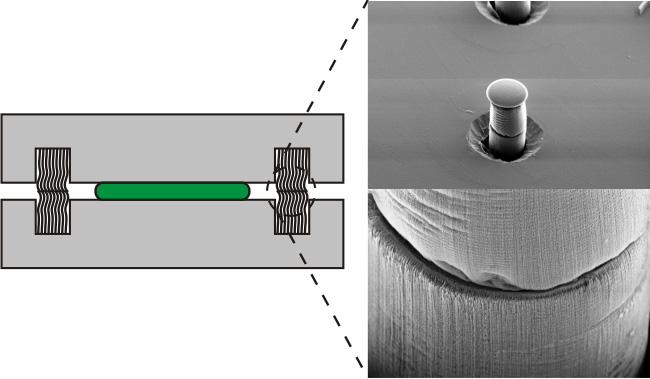

| Two chips have interconnects that are filled with thousands of carbon nanotubes. The chips are then bonded with adhesive so that the carbon nanotubes are directly contacted. A connection using two such interconnects is pictured to the right. Image credit: Teng Wang, Kjell Jeppson, Lilei Ye, Johan Liu. Carbon-Nanotube Through-Silicon Via Interconnects for Three-Dimensional Integration. Small, 2011, Volume 7, pages 2,313–2,317. Copyright Wiley-VCH Verlag GmbH & Co. KGaA. |

Abstract:

Researchers at Chalmers have demonstrated that two stacked chips can be vertically interconnected with carbon nanotube vias through the chips. This new method improves possibilities for 3D integration of circuits, one of the most promising approaches for miniaturization and performance promotion of electronics.

Carbon nanotubes best for 3D electronics

Gothenburg, Sweden | Posted on December 12th, 2011Three dimensional integration is a hot field within electronics since it offers a new way to package components densely and thus build tiny, well-functioning units. When stacking chips vertically, the most effective way to interconnect them is with electrical interconnects that go through the chip (instead of being wired together at the edges) - what are known as through-silicon vias.

The industry thus far has primarily used copper for this purpose; however, copper has several disadvantages that can limit the reliability of 3D electronics. Another major issue involves cooling when the chips get hot. The excellent thermal qualities of carbon nanotubes can play a decisive role in this respect.

Thus a research team at Chalmers is working with carbon nanotubes as conductive material for through-silicon vias. Carbon nanotubes - or tubes made of graphene whose walls are only one atom thick - are going to be the most reliable of all conductive materials if it is possible to use them on a large scale. This is the opinion of Kjell Jeppsson, a member of the research team.

"Potentially, carbon nanotubes have much better properties than copper, both in terms of thermal and electrical conductivity", he says. "Carbon nanotubes are also better suited for use with silicon from a purely mechanical point of view. They expand about the same amount as the surrounding silicon while copper expands more, which results in mechanical tension that can cause the components to break."

The researchers have demonstrated that two chips can be vertically interconnected with carbon nanotubes by through-silicon via interconnects, and that the chips can be bonded. They have also demonstrated that the same method can be used for electrical interconnection between the chip and the package.

PhD student Teng Wang - who defends his thesis on 12 December - has worked on production. He has developed a technique to fill through-silicon vias with thousands of carbon nanotubes. The chips are then bonded with an adhesive so that the carbon nanotubes are directly contacted and can thus conduct current through the chips.

"One difficulty involves producing carbon nanotubes with perfect properties and with the length we need to go through the chip," he says. "We have produced tubes that are 200 micrometers long, which can be compared to the diameter which is only 10 nanometers. Their properties, however, are not yet perfect."

For the method to be transferred to industrial production, manufacturing temperature needs to be reduced to a maximum of 450 degrees. This is a great challenge since carbon nanotubes are currently "grown" at a minimum of 700 degrees.

If successful, entirely new possibilities will arise for future shrinking of electronics - not least in terms of improved performance. The three dimensional integration using through-silicon vias provides significantly quicker signal transfers than traditional integration where chips are placed next to each other. Furthermore, through-silicon vias with carbon nanotubes provide less expensive production compared to the current technology that uses copper interconnects.

"There are several projects involving 3D integration underway in the industry, but there are potential problems with both cooling and reliability since they use copper," says Kjell Jeppsson. "If our method works on a large scale, I believe it will be in production within five years."

####

For more information, please click here

Contacts:

Kjell Jeppson

Department of Microtechnology and Nanoscience

+46 31-772 1856

Teng Wang

Department of Microtechnology and Nanoscience

+46 31-772 3092

Johan Liu

Department of Microtechnology and Nanoscience

+46 31-772 3067

Copyright © Chalmers University of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() The PhD thesis that is defended on December 12:

The PhD thesis that is defended on December 12:

![]() Read the researchers' articles in the scientific journals Small and Advanced Materials:

Read the researchers' articles in the scientific journals Small and Advanced Materials:

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||