Home > Press > RUSNANO to Invest in Basalt Plastics Production

|

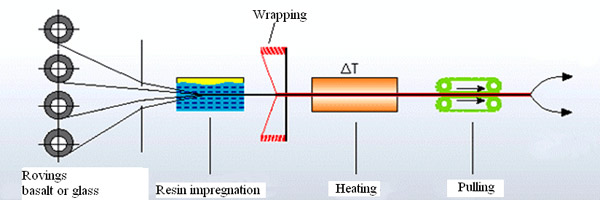

| Diagram of Galen’s pultrusion unit |

Abstract:

RUSNANO and Galen company have signed an investment agreement for establishing production of composite nanostructured polymer based on basalt fiber. The project has a total budget of 500 million rubles of which RUSNANO will co-invest 200 million rubles. Project planners expect production to reach 2,500 tons to 3,000 tons in 2016. Products include shaft lining for the mining industry; armature, flexible connectors, and rawl plugs for the construction industry; composite alluvial drill rods for oil production; and poles for street lighting and power transmission lines.

RUSNANO to Invest in Basalt Plastics Production

Moscow, Russia | Posted on October 27th, 2011Basalt plastic armature is as strong as steel and a great deal more durable. Moreover, composite material based on basalt fiber does not corrode. This is very important for structures that must operate where moisture is high or salt is present, particularly bridge supports. The material is considerably lighter than steel (on average 70 percent), simplifying transportation and making it less costly. Under some circumstances, the material extends the service life of equipment by reducing the stress load, for example, in alluvial drill rods used to produce oil. Because the composite is shock absorbent and impact safe, the material is ideally suited to street lighting poles.

"Galen is experienced in developing unique technological solutions. Take, for example its armature for construction of a single-span bridge in Northern Ireland or its flexible connectors for the Passive House in England, an innovative project. By the way, the strict requirement the British had for fire resistance of materials prompted the company's engineers to begin experiments with nanomodifiers for polymer connectors," noted RUSNANO Managing Director Alexander Kondrashov.

The composite materials that Galen manufactures contain basalt fiber produced using pultrusion, a continuous molding process, with an epoxy binder that is resistant to halogens, acids, and alkalis. The disadvantage of the composite's relatively low combustion temperature has been overcome by adding to the epoxy binder a small amount of nanoparticles of aluminosilicate montmorillonite based largely on clay. This also improves the strength of the composite under flexion.

Technical information

Pultrusion is a production technology for manufacturing construction industry items using plastic fibers in a continuous process. The name pultrusion comes from the English words pull and extrusion. Saturated with polymer binding material, the filler (rope, linen, woven tape, fiberglass, carbon fiber, or organic fiber) is stretched through a heated die that determines its form. The polymer binder is usually made of epoxy resin, unsaturated polyesters, or thermoplastics. Galen uses epoxy resins to which nanoparticles of aluminosilicate montmorillonite have been added for chemical stability, resistance to heat, and impact and fatigue endurance.

This particular method for preparing composite materials has superior compatibility with the environment: СО2 emissions during production of a single run of basalt plastic are one thirty-fifth to one forty-ninth the СО2 emitted during production of regular steel or stainless steel armature. Measured by energy consumption, a kilogram of the composite armature requires only two kilowatts to produce while a kilogram of the steel armature consumes three times the energy.

####

About RUSNANO

RUSNANO was founded in March 2011 as an open joint stock company through reorganization of state corporation Russian Corporation of Nanotechnologies. RUSNANO’s mission is to develop the Russian nanotechnology industry through co-investment in nanotechnology projects with substantial economic potential or social benefit. The Government of the Russian Federation owns 100 percent of the shares in RUSNANO. Anatoly Chubais is CEO and chairman of the Executive Board of RUSNANO.

Work to establish nanotechnology infrastructure and training for nanotechnology specialists, formerly conducted by the Russian Corporation of Nanotechnologies, has been entrusted to the Fund for Infrastructure and Educational Programs, a non-commercial fund also established through reorganization of the Russian Corporation of Nanotechnologies.

For more information, please click here

Contacts:

10A Prospekt 60-letia Oktyabrya

Moscow, Russia

117036

P: +7 495 988 5388

F: +7 495 988 5399

Copyright © RUSNANO

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

VC/Funding/Angel financing/Loans/Leases/Crowdfunding

![]() Graphene Flagship start-up Bedimensional closes a second €10 million investment round February 10th, 2023

Graphene Flagship start-up Bedimensional closes a second €10 million investment round February 10th, 2023

![]() 180 Degree Capital Corp. Issues Second Open Letter to the Board and Shareholders of Enzo Biochem, Inc. March 26th, 2021

180 Degree Capital Corp. Issues Second Open Letter to the Board and Shareholders of Enzo Biochem, Inc. March 26th, 2021

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Construction

![]() Temperature-sensing building material changes color to save energy January 27th, 2023

Temperature-sensing building material changes color to save energy January 27th, 2023

![]() Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

![]() A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

![]() Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||