Home > Press > New Nano-Based Process Simplifies Magnetic Manufacture

|

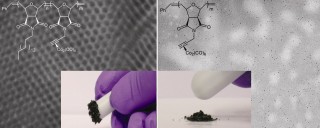

| Tew Research Group, UMass Amherst

Figure shows the block copolymer (left) and homopolymer (right) samples. The background of both figures is a transmission electron microscopy image showing that the block copolymer is made of nanoscopic domains visualized as a honeycomb pattern of cobalt-rich cylinders while the homopolymer is unstructured but contains small cobalt particles shown in black. Similar small cobalt particles are present in the block copolymer but they are not easily observed due to the nanoscopic block copolymer super-structure. The chemical structure of both polymers is also shown along with powder samples of the two materials. The block copolymer is attracted to the white magnet bar shown in the photograph while the non-magnetic homopolymer sample has no such attraction. |

Abstract:

Scientists at the University of Massachusetts Amherst report that for the first time they have designed a much simpler method of preparing ordered magnetic materials than ever before, by coupling magnetic properties to nanostructure formation at low temperatures.

New Nano-Based Process Simplifies Magnetic Manufacture

Amherst, MA | Posted on September 27th, 2011The innovative process allows them to create room-temperature ferromagnetic materials that are stable for long periods more effectively and with fewer steps than more complicated existing methods. The approach is outlined by UMass Amherst polymer scientist Gregory Tew and colleagues in the Sept. 27 issue of Nature Communications.

Tew explains that his group's signature improvement is a one-step method to generate ordered magnetic materials based on cobalt nanostructures by encoding a block copolymer with the appropriate chemical information to self-organize into nanoscopic domains. Block copolymers are made up of two or more single-polymer subunits linked by covalent chemical bonds.

The new process delivers magnetic properties to materials upon heating the sample once to a relatively low temperature, about 390 degrees (200 degrees Celsius), which transforms them into room-temperature, fully magnetic materials. Most previous processes required either much higher temperatures or more process steps to achieve the same result, which increases costs, Tew says.

He adds, "The small cobalt particles should not be magnetic at room temperature because they are too small. However, the block copolymer's nanostructure confines them locally which apparently induces stronger magnetic interactions among the particles, yielding room-temperature ferromagnetic materials that have many practical applications."

"Until now, it has not been possible to produce ordered, magnetic materials via block copolymers in a simple process," Tew says. "Current methods require multiple steps just to generate the ordered magnetic materials. They also have limited effectiveness because they may not retain the fidelity of the ordered block copolymer, they can't confine the magnetic materials to one domain of the block copolymer, or they just don't produce strongly magnetic materials. Our process answers all these limitations."

Magnetic materials are used in everything from memory storage devices in our phones and computers to the data strips on debit and credit cards. Tew and colleagues have discovered a way to build block copolymers with the necessary chemical information to self-organize into nanoscopic structures one millionth of a millimeter thin, or about 50,000 times thinner than the average human hair.

Earlier studies have demonstrated that block copolymers can be organized over relatively large areas. What makes the UMass Amherst research group's results so intriguing, Tew says, is the possible coupling of long-range organization with improved magnetic properties. This could translate into lower-cost development of new memory media, giant magneto-resistive devices and futuristic spintronic devices that might include "instant on" computers or computers that require much less power, he points out.

He adds, "Although work remains to be done before new data storage applications are enabled, for example making the magnets harder, our process is highly tunable and therefore amendable to incorporating different types of metal precursors. This result should be interesting to every scientist in nanotechnology because it shows conclusively that nano-confinement leds to completely new properties, in this case room temperature magnetic materials."

"Our work highlights the importance of learning how to control a material's nanostructure. We show that the nanostructure is directly related to an important and practical outcome, that is, the ability to generate room-temperature magnets."

"Our work highlights the importance of learning how to control a material's nanostructure. We show that the nanostructure is directly related to an important and practical outcome, that is, the ability to generate room temperature magnets." As part of this study, the UMass Amherst team also demonstrated that using a block copolymer or nanoscopic material results in a material that is magnetic at room temperature. By contrast, using a homopolymer, or unstructured material, leads only to far less useful non- or partial-magnetic materials.

####

For more information, please click here

Contacts:

Gregory N. Tew

413-577-1612

Copyright © Newswise

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Memory Technology

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Researchers discover materials exhibiting huge magnetoresistance June 9th, 2023

Researchers discover materials exhibiting huge magnetoresistance June 9th, 2023

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||