Home > Press > A “Nano,” Environmentally Friendly, and Low Toxicity Flame Retardant Protects Fabric

|

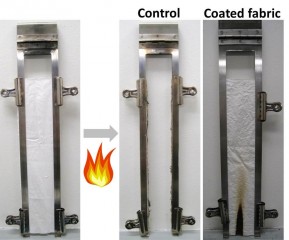

| Credit: Jaime Grunlan, Ph.D. Fire completely destroys untreated cotton fabric until nothing remains (control), but only burns a small spot on cotton treated with a new flame-retardant nanocoating (coated fabric). |

Abstract:

The technology in "fire paint" used to protect steel beams in buildings and other structures has found a new life as a first-of-its-kind flame retardant for children's cotton sleepwear, terrycloth bathrobes and other apparel, according to a report presented here today at the 242nd National Meeting & Exposition of the American Chemical Society (ACS).

A “Nano,” Environmentally Friendly, and Low Toxicity Flame Retardant Protects Fabric

Denver, CO | Posted on September 1st, 2011"People are concerned about the potential toxicity of flame retardants that are currently used on a variety of products, especially children's pajamas and the foam in children's car seats," said Jaime C. Grunlan, Ph.D., who led the research. "The water-based ingredients in this new coating are much less toxic to humans than the so-called ‘halogenated' or ‘brominated' flame retardants used in the past, and they are more environmentally friendly."

Grunlan explained that flame retardants are used on cotton, the most popular fabric in the world, because it can catch fire easily and burns rapidly with a hot flame. Flame retardants make it more difficult for fabrics to ignite, make them burn slower and make fabrics self-extinguish when the flame is removed. That margin of safety is especially important for clothing fires, which can cause severe and disfiguring injuries. Flame retardants allow time to remove the clothing or put out the flames.

In responding to the need for more environmentally friendly flame retardants, Grunlan's team turned to a technology termed "intumescence," long used to fireproof exposed interior steel beams in buildings. At the first lick of a flame, an intumescent coating swells up and expands like beer foam, forming tiny bubbles in a protective barrier that insulates and shields the material below. The researchers are at Texas A&M University in College Station.

"This work is the first demonstration of a polymer-based ‘nano intumescent'," said Grunlan. "We believe it has great potential for use as flame retardants on clothing and other materials in order to avoid some of the disadvantages of existing products."

The material is "nano," or ultra-small, built up from layers of alternating positively and negatively charged polymers so thin that almost 50,000 would fit across the width of a human hair. Size has an advantage, Grunlan explained. Because these layers are so thin, the polymer liquid seeps deep into cotton fabric and onto each individual cotton fiber. Existing flame retardants, in contrast, simply settle on fiber bundles like armor and slow the spread of flames, but the fabric still burns and turns black. When the new nano coating is exposed to a flame, it expands slightly and stops the fire from igniting and burning the fabric — which remains white, except for the small area where the cotton directly touches the flame.

Grunlan noted that the new flame retardant addresses public concerns about the potential toxicity of flame retardants now used on a variety of products, especially children's pajamas and the foam inside children's car seats and toys, and pointed out that the water-based polymers used in the nanocoating are much less toxic to humans than other flame retardants used today.

Would clothing coated with the nano intumescent be stiff and dull? "The look and texture of the fabric would depend on the thickness of the coating and also on the specific polymer we use," Grunlan pointed out. The nanocoating is deposited in alternate layers of positively and negatively charged polymers; swapping one of those polymers out for a different one in the recipe could offer similar anti-flammable protection while making the fabric softer.

Grunlan's team is in the process of optimizing the flame retardant so that it remains on cotton fabrics despite frequent laundering. "We haven't done anything yet to protect the coating, but we believe that with further research, we could make this an almost permanent addition to the fabric," he explained.

They also plan to test the coating on other materials, such as polyester and foam, possibly with commercial partners.

####

About American Chemical Society (ACS)

The American Chemical Society is a non-profit organization chartered by the U.S. Congress. With more than 163,000 members, ACS is the world’s largest scientific society and a global leader in providing access to chemistry-related research through its multiple databases, peer-reviewed journals and scientific conferences. Its main offices are in Washington, D.C., and Columbus, Ohio.

For more information, please click here

Contacts:

Michael Bernstein

303-228-8532 (Aug. 25-Sept. 1)

202-872-6042 (Before Aug. 25)

Michael Woods

303-228-8532 (Aug. 25-Sept. 1)

202-872-6293 (Before Aug. 25)

Copyright © Newswise

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Home

![]() Nanomaterials enable dual-mode heating and cooling device: Device could cut HVAC energy use by nearly 20% in the US December 2nd, 2020

Nanomaterials enable dual-mode heating and cooling device: Device could cut HVAC energy use by nearly 20% in the US December 2nd, 2020

![]() Bosch Sensortec launches ideation community to foster and accelerate innovative IoT applications : Creativity hub for customers, partners, developers and makers February 18th, 2019

Bosch Sensortec launches ideation community to foster and accelerate innovative IoT applications : Creativity hub for customers, partners, developers and makers February 18th, 2019

![]() Iran Develops Water-Repellent Nano-Paint December 5th, 2018

Iran Develops Water-Repellent Nano-Paint December 5th, 2018

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||