Home > Press > AIJU compares the plastic processing properties on an industrial and laboratory scale

|

Abstract:

The RDT undertakes the comparative study of tensile mechanical properties of plastic materials processed on an industrial and laboratory scale.

AIJU compares the plastic processing properties on an industrial and laboratory scale

Spain | Posted on May 27th, 2011One of the more attractive fronts within the plastic industry is that of new materials development with improved properties (mechanical, electric, thermal, optical, fire-resistant, barrier, etc.). In this sense, nanoparticles have achieved great importance as they offer a lot of possibilities at the time of mixing additives to conventional plastics, improving the characteristic properties of the original material.

Nevertheless, these nanoparticles can be especially expensive, ranging from 100• Kg up to 5000• Kg for the most specialised, with the machinery transformation sector evolving in parallel.

That is why the Toy Research Institute (AIJU) has complemented the working line for the development of new materials with micro-extrusion and mini-injection equipment to achieve the mechanical characterization of new formulations. Within the framework of this study, tensile tests have been carried out on test specimens, both with and without added materials.

Miguel A. León, the technical manager in AIJU for this study explains that: "The tensile properties have been studied which are the most important indicators of the material resistance, in which both, the strength required to pull the test specimen as well as the enlargement during the whole test are registered."

Within the study, the conclusion reached was that injection moulding of thermoplastic materials on a laboratory scale reproduces the same results obtained on an industrial scale, thus being a valid alternative in the case of having a low amount of raw material or that these materials have a high cost, as would be the case with nanoadditives or nanocharges.

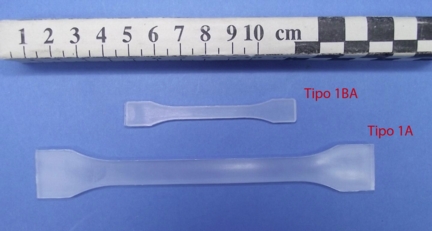

Another notable aspect of this study is that the standard test specimen is not a critical factor, according to the results obtained in the tensile tests for both, test specimen type 1A as well as test specimen type 1BA.

These results have been obtained thanks to the financial support of the Conselleria de Industria Comercio e Innovación and the MITYC through the financing of projects INIDIV/2010/63 and SUP-040100-2010-0039, respectively.

####

About AIJU

The Toy Research Institute (AIJU) is a non-profit making organisation, located in Ibi, the Spanish geographic centre for the manufacture of toys. It was founded in 1985 with the collaboration of the Spanish Toy Manufacturers Association (AEFJ) and the Regional Government (IMPIVA).

Its aim is to transfer and allow toy manufacturers access to the knowledge of new technologies in order to improve their competitivity, while offering technological and financial assessment and supporting the professional development of people involved in the sector. For this purpose, it has a staff of 75 professionals who develop their work in the different departments that make up AIJU. Moreover, this organization has the required infrastructure to manage the different activities it undertakes.

The department intended to carry out these tasks is that of Product Development ˆ Laboratory Department, specifically the Processing and Materials area. This area has several research lines for the development of new materials both, for traditional technologies and rapid manufacturing technologies. The area carrying out this project has been working closely with the Rapid Manufacturing area for 10 years now with the objective of reaching final material sets.

AIJU is an active member of the Technological Platform for Traditional Manufacturing Sectors, the Rapid Manufacturing European Platform and the Spanish mirror led by ASERM, the Spanish Rapid Manufacturing Association. It is also member of EuMAT and Manufuture. AIJU is the coordinator of the working group "Rapid Prototyping Proposal SP3 (materials) Lab" and member of the "Materials" group promoted by REDIT, the RDT Centres of IMPIVA‚s Network.

In the field of standardisation, the entity is working on the potential feasibility of proposed legislation as well as new safety criteria for toys, with participation in several proficiency testing schemes both, on a National and European Level. Thus, it is participating in the development of new standards for toys in the European Committee of Normalization (CEN).

For more information, please click here

Contacts:

Miguel A. León

Phone: +34965554475

Fax: +34965554490

E-mail:

Copyright © AIJU

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Alliances/Trade associations/Partnerships/Distributorships

![]() Chicago Quantum Exchange welcomes six new partners highlighting quantum technology solutions, from Chicago and beyond September 23rd, 2022

Chicago Quantum Exchange welcomes six new partners highlighting quantum technology solutions, from Chicago and beyond September 23rd, 2022

![]() University of Illinois Chicago joins Brookhaven Lab's Quantum Center June 10th, 2022

University of Illinois Chicago joins Brookhaven Lab's Quantum Center June 10th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||