Home > Press > Seeing below the surface: Engineers devise a new way to inspect advanced materials used to build airplanes

|

Abstract:

In recent years, many airplane manufacturers have started building their planes from advanced composite materials, which consist of high-strength fibers, such as carbon or glass, embedded in a plastic or metal matrix. Such materials are stronger and more lightweight than aluminum, but they are also more difficult to inspect for damage, because their surfaces usually don't reveal underlying problems.

Seeing below the surface: Engineers devise a new way to inspect advanced materials used to build airplanes

Cambridge, MA | Posted on March 27th, 2011"With aluminum, if you hit it, there's a dent there. With a composite, oftentimes if you hit it, there's no surface damage, even though there may be internal damage," says Brian L. Wardle, associate professor of aeronautics and astronautics.

Wardle and his colleagues have devised a new way to detect that internal damage, using a simple handheld device and heat-sensitive camera. Their approach also requires engineering the composite materials to include carbon nanotubes, which generate the heat necessary for the test.

Their approach, described in the March 22 online edition of the journal Nanotechnology, could allow airlines to inspect their planes much more quickly, Wardle says. This project is part of a multiyear, aerospace-industry-funded effort to improve the mechanical properties of existing advanced aerospace-grade composites. The U.S. Air Force and Navy are also interested in the technology, and Wardle is working with them to develop it for use in their aircraft and vessels.

Uncovering damage

Advanced composite materials are commonly found not only in aircraft, but also cars, bridges and wind-turbine blades, Wardle says.

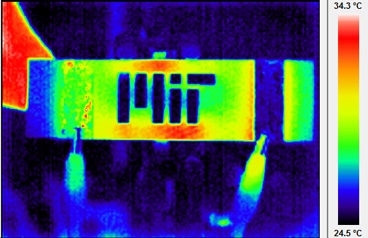

One method that inspectors now use to reveal damage in advanced composite materials is infrared thermography, which detects infrared radiation emitted when the surface is heated. In an advanced composite material, any cracks or delamination (separation of the layers that form the composite material) will redirect the flow of heat. That abnormal flow pattern can be seen with a heat-sensitive (thermographic) camera.

This is effective but cumbersome because it requires large heaters to be placed next to the surface, Wardle says. With his new approach, carbon nanotubes are incorporated into the composite material. When a small electric current is applied to the surface, the nanotubes heat up, which eliminates the need for any external heat source. The inspector can see the damage with a thermographic camera or goggles.

"It's a very clever way to utilize the properties of carbon nanotubes to deliver that thermal energy, from the inside out," says Douglas Adams, associate professor of mechanical engineering at Purdue University. Adams, who was not involved in the research, notes that two fundamental challenges remain: developing a practical way to manufacture large quantities of the new material, and ensuring that the addition of nanotubes does not detract from the material's primary function of withstanding heavy loads.

The new carbon nanotube hybrid materials that Wardle is developing have so far shown better mechanical properties, such as strength and toughness, than existing advanced composites.

####

For more information, please click here

Contacts:

Anne Trafton

MIT News Office

617.253.2700

Copyright © MIT

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Aerospace/Space

![]() Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

![]() Bridging light and electrons January 12th, 2024

Bridging light and electrons January 12th, 2024

![]() Manufacturing advances bring material back in vogue January 20th, 2023

Manufacturing advances bring material back in vogue January 20th, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||