Home > Press > 3D printing method advances electrically small antenna design

|

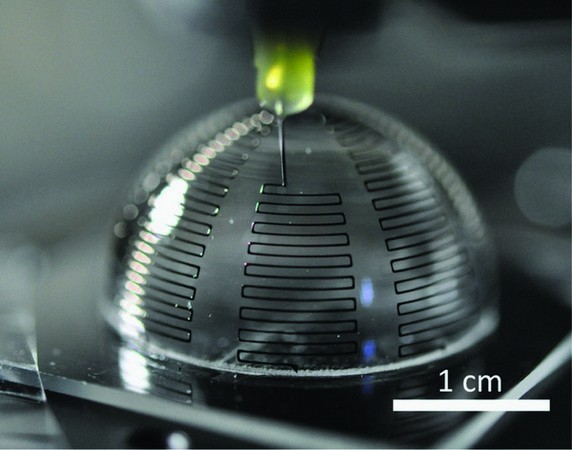

| Optical image of an antenna during the printing process. |

Abstract:

While most electronic components benefit from decreased size, antennas-whether in a cell phone or on an aircraft-suffer limitations in gain, efficiency, system range, and bandwidth when their size is reduced below a quarter-wavelength.

3D printing method advances electrically small antenna design

Champaign, IL | Posted on March 20th, 2011"Recent attention has been directed toward producing antennas by screen-printing, inkjet printing, and liquid metal-filled microfluidics in simple motifs, such as dipoles and loops," explained Jennifer T. Bernhard, a professor of electrical and computer engineering at Illinois. "However, these fabrication techniques are limited in both spatial resolution and dimensionality, yielding planar antennas that occupy a large area relative to the achieved performance."

"Omnidirectional printing of metallic nanoparticle inks offers an attractive alternative for meeting the demanding form factors of 3D electrically small antennas (ESAs)," stated Jennifer A. Lewis, the Hans Thurnauer Professor of Materials Science and Engineering and director of the Frederick Seitz Materials Research Laboratory at Illinois.

"To our knowledge, this is the first demonstration of 3D printed antennas on curvilinear surfaces," Lewis stated. The research findings and fabrication methods developed by Bernhard, Lewis, and their colleagues are featured in the cover article,"Illinois Calling" of the March 18 issue of Advanced Materials ("Conformal Printing of Electrically Small Antennas on Three-Dimensional Surfaces").

According to Bernhard, these antennas are electrically small relative to a wavelength (typically a twelfth of a wavelength or less) and exhibit performance metrics that are an order of magnitude better than those realized by monopole antenna designs.

"There has been a long-standing problem of minimizing the ratio of energy stored to energy radiated-the Q-of an ESA," Bernhard explained. "By printing directly on the hemispherical substrate, we have a highly versatile single-mode antenna with a Q that very closely approaches the fundamental limit dictated by physics (known as the Chu limit).

Conformal printing allows the antenna's meander lines to be printed on the outside or inside of hemispherical substrates, adding to its flexibility.

"Unlike planar substrates, the surface normal is constantly changing on curvilinear surfaces, which presents added fabrication challenges," Lewis noted. To conformally print features on hemispherical substrates, the silver ink must strongly wet the surface to facilitate patterning even when the deposition nozzle (100 μm diameter) is perpendicular to the printing surface.

To fabricate an antenna that can withstand mechanical handling, for example, the silver nanoparticle ink is printed on the interior surface of glass hemispheres. Other non-spherical ESAs can be designed and printed using a similar approach to enable integration of low Q antennas on, for example, the inside of a cell phone case or the wing of an unmanned aerial vehicle. The antenna's operating frequency is determined primarily by the printed conductor cross-section and the spacing (or pitch) between meander lines within each arm.

According to the researchers, their design can be rapidly adapted to new specifications, including other operating frequencies, device sizes, or encapsulated designs that offer enhanced mechanical robustness.

"This conformal printing technique can be extended other potential applications, including flexible, implantable, and wearable antennas, electronics, and sensors," Lewis said.

####

For more information, please click here

Contacts:

Jennifer T. Bernhard

Department of Electrical and Computer Engineering

University of Illinois at Urbana-Champaign

217/333-0293

Jennifer A. Lewis

Frederick Seitz Materials Research Laboratory

217/244-4973

If you have any questions about the College of Engineering, or other story ideas, contact

Rick Kubetz

writer/editor

Engineering Communications Office

University of Illinois at Urbana-Champaign

217/244-7716

Copyright © University of Illinois at Urbana-Champaign

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

3D & 4D printing/Additive-manufacturing

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

![]() 3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Sensors

Nanoelectronics

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

![]() Reduced power consumption in semiconductor devices September 23rd, 2022

Reduced power consumption in semiconductor devices September 23rd, 2022

![]() Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Printing/Lithography/Inkjet/Inks/Bio-printing/Dyes

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

![]() Disposable electronics on a simple sheet of paper October 7th, 2022

Disposable electronics on a simple sheet of paper October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||