Home > Press > Atomic-scale printing is Owl-right: Rice University researchers create single-atom lithography in graphene

|

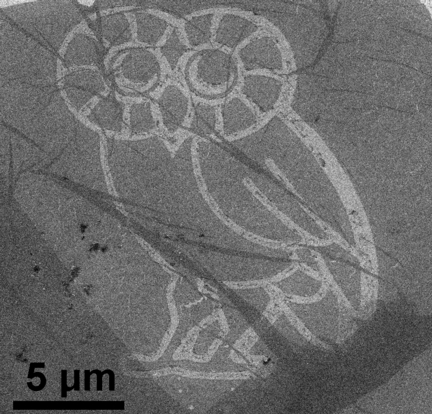

| A Rice University owl about 15 millionths of a meter wide was patterned in a single layer of graphene by Ayrat Dimiev, a postdoctoral researcher in the Rice lab of Professor James Tour. The work is part of a new paper in this week's edition of the journal Science. (Credit: Tour Lab/Rice University) |

Abstract:

A little zinc can do a lot of damage to graphene. Rice University researchers have taken advantage of that to create single-atomic-layer lithography.

The Rice lab of chemist James Tour reported this week in the journal Science that sputtering zinc onto multilayered graphene enabled the team to remove a single layer at a time without disturbing the layers beneath.

Atomic-scale printing is Owl-right: Rice University researchers create single-atom lithography in graphene

Houston, TX | Posted on March 3rd, 2011The discovery could be useful as researchers explore graphene's electrical properties for new generations of microcircuitry and other graphene-based devices. Graphene, the one-atom-thick form of carbon, won its discoverers the most recent Nobel Prize in physics.

The researchers created a graphene checkerboard by removing horizontal and vertical layers to create a three-dimensional pattern.

They also printed a micro owl, Rice's mascot, about 15 millionths of a meter wide.

"The removal of a single sheet of graphene or graphene oxide was a surprise," said Tour, Rice's T.T. and W.F. Chao Chair in Chemistry as well as a professor of mechanical engineering and materials science and of computer science. "We thought multiple layers would be removed by this protocol, but to see single layers removed is one of those exciting events in science where nature gives us far more than we expected."

Tour said the ability to remove single layers of graphene in a controlled manner "affords the most precise level of device-patterning ever known, or ever to be known, where we have single-atom resolution in the vertical dimension. This will forever be the limit of vertical patterning -- we have hit the bottom of the scale."

Ayrat Dimiev, a postdoctoral scientist in Tour's lab, discovered the technique and figured out why graphene is so amenable to patterning. He sputtered zinc onto graphene oxide and other variants created through chemical conversion, chemical vapor deposition and micromechanically (the "Scotch-tape" method). Bathing the graphene in dilute hydrochloric acid removed graphene wherever the zinc touched it, leaving the layers underneath intact. The graphene was then rinsed with water and dried in a stream of nitrogen.

For the owl, Dimiev cut a stencil in PMMA with an electron beam and placed it on graphene oxide. He sputter-coated zinc through the stencil and then washed the zinc away with dilute hydrochloric acid, leaving the embedded owl behind.

Sputter-coating graphene with aluminum showed similar effects. But when Dimiev tried applying zinc via thermal evaporation, the graphene stayed intact.

Investigation of the sputtered surface before applying the acid wash revealed that the metals formed defects in the graphene, breaking bonds with the surrounding sheet like a cutter through chicken wire. Sputtering zinc, aluminum, gold and copper all produced similar effects, though zinc was best at delivering the desired patterning.

The researchers were able to create a 100-nanometer line in a sheet of graphene, which suggests the only horizontal limit to the resolution of the process is the resolution of the metal patterning method.

"The next step will be to control the horizontal patterning with similar precision to what we have attained in the vertical dimension," Tour said. "Then there's no more room at the bottom at any dimension, at least if we call single atoms our endpoint -- which it is, for practical purposes."

Co-authors include research associate Dmitry Kosynkin, postdoctoral research associate Alexander Sinitskii and graduate students Alexander Slesarev and Zhengzong Sun, all of Rice.

The Air Force Office of Scientific Research, the Air Force Research Lab through the University Technology Corporation, the Office of Naval Research Graphene MURI Program, and M-I SWACO funded the research.

####

About Rice University

Located in Houston, Rice University is consistently ranked among the nation's top 20 universities by U.S. News & World Report. A Tier One research university known for its "unconventional wisdom," Rice has schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and offers its 3,485 undergraduates and 2,275 graduate students a wide range of majors. Rice has the fifth-largest endowment per student among American private research universities and is rated No. 4 for “best value” among private universities by Kiplinger’s Personal Finance. Its undergraduate student-to-faculty ratio is less than 6-to-1. With a residential college system that builds close-knit and diverse communities and collaborative culture, Rice has been ranked No. 1 for best quality of life multiple times by the Princeton Review.

For more information, please click here

Contacts:

David Ruth

713-348-6327

Mike Williams

713-348-6728

Copyright © Rice University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Military

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() New chip opens door to AI computing at light speed February 16th, 2024

New chip opens door to AI computing at light speed February 16th, 2024

Printing/Lithography/Inkjet/Inks/Bio-printing/Dyes

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

![]() Disposable electronics on a simple sheet of paper October 7th, 2022

Disposable electronics on a simple sheet of paper October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||