Home > Press > How do you cut a nanotube? Lots of compression.

|

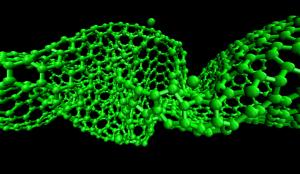

| Sound of slicing: High-intensity atomic-level sonic boomlets cause nanotubes to buckle and twist at “compression-concentration zones.” Credit: Kim Lab/Brown University |

Abstract:

Researchers at Brown University and in Korea have described the dynamics behind cutting single-walled carbon nanotubes, cylindrical structures just 1/50,000th the width of a human hair. The tubes are compressed by potent sonic booms, causing them to buckle at certain points at helical, 90-degree angles. The finding could lead to better-quality nanotubes for potential use in automotive, electronics, optics and other fields. Results appear in the Proceedings of the Royal Society A.

How do you cut a nanotube? Lots of compression.

Providence, RI | Posted on December 21st, 2010A pipefitter knows how to make an exact cut on a metal rod. But it's far harder to imagine getting a precise cut on a carbon nanotube, with a diameter 1/50,000th the thickness of a human hair.

In a paper published this month in the British journal Proceedings of the Royal Society A, researchers at Brown University and in Korea document for the first time how single-walled carbon nanotubes are cut, a finding that could lead to producing more precise, higher-quality nanotubes. Such manufacturing improvements likely would make the nanotubes more attractive for use in automotive, biomedicine, electronics, energy, optics and many other fields.

"We can now design the cutting rate and the diameters we want to cut," said Kyung-Suk Kim, professor of engineering in the School of Engineering at Brown and the corresponding author on the paper.

The basics of carbon nanotube manufacturing are known. Single-atom thin graphene sheets are immersed in solution (usually water), causing them to look like a plate of tangled spaghetti. The jumbled bundle of nanotubes is then blasted by high-intensity sound waves that create cavities (or partial vacuums) in the solution. The bubbles that arise from these cavities expand and collapse so violently that the heat in each bubble's core can reach more than 5,000 degrees Kelvin, close to the temperature on the surface of the sun. Meanwhile, each bubble compresses at an acceleration 100 billion times greater than gravity. Considering the terrific energy involved, it's hardly surprising that the tubes come out at random lengths. Technicians use sieves to get tubes of the desired length. The technique is inexact partly because no one was sure what caused the tubes to fracture.

Materials scientists initially thought the super-hot temperatures caused the nanotubes to tear. A group of German researchers proposed that it was the sonic boomlets caused by collapsing bubbles that pulled the tubes apart, like a rope tugged so violently at each end that it eventually rips.

Kim, Brown postdoctoral researcher Huck Beng Chew, and engineers at the Korea Institute of Science and Technology decided to investigate further. They crafted complex molecular dynamics simulations using an array of supercomputers to tease out what caused the carbon nanotubes to break. They found that rather than being pulled apart, as the German researchers had thought, the tubes were being compressed mightily from both ends. This caused a buckling in a roughly five-nanometer section along the tubes called the compression-concentration zone. In that zone, the tube is twisted into alternating 90-degree-angle folds, so that it fairly resembles a helix.

That discovery still did not explain fully how the tubes are cut. Through more computerized simulations, the group learned the mighty force exerted by the bubbles' sonic booms caused atoms to be shot off the tube's lattice-like foundation like bullets from a machine gun.

"It's almost as if an orange is being squeezed, and the liquid is shooting out sideways," Kim said. "This kind of fracture by compressive atom ejection has never been observed before in any kind of materials."

The team confirmed the computerized simulations through laboratory tests involving sonication and electron microscopy of single-walled carbon nanotubes.

The group also learned that cutting single-walled carbon nanotubes using sound waves in water creates multiple kinks, or bent areas, along the tubes' length. The kinks are "highly attractive intramolecular junctions for building molecular-scale electronics," the researchers wrote.

Huck Beng Chew, a postdoctoral researcher in Brown's School of Engineering, is the first author on the paper. Myoung-Woon Moon and Kwang Ryul Lee, from the Korea Institute of Science and Technology, contributed to the research. The U.S. National Science Foundation and the Korea Institute of Science and Technology funded the work.

####

For more information, please click here

Contacts:

Richard Lewis

(401) 863-3766

Copyright © Brown University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Videos/Movies

![]() New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

![]() Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

![]() Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

![]() Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Academic/Education

![]() Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

![]() Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||