Home > Press > Innovative method to fabricate complex 3D microstructures

|

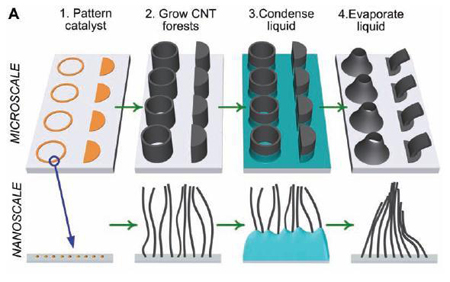

| Illustration of CNT forest growth and capillary forming sequence |

Abstract:

Researchers from imec and the University of Michigan have reported a new technology to fabricate complex three-dimensional microstructures, with intricate bends, twists, and multidirectional textures, starting from vertically aligned carbon nanotubes (CNT). The resulting assemblies have a mechanical stiffness exceeding that of microfabrication polymers, and can be used as molds for the mass production of 3D polymer structures. The method is straightforward, in that it requires only standard two-dimensional patterning and thermal processing at ambient pressure.

Innovative method to fabricate complex 3D microstructures

Leuven, Belgium & Ann Arbor, MI | Posted on December 18th, 2010Complex surfaces with precisely fabricated nanosized features are needed in, for example, metamaterials, substrates for cell culture and tissue engineering, smart active surfaces, and lab-on-a-chip systems. But existing methods of fabricating 3D microstructures all have their drawbacks, requiring tradeoffs in feature geometry, heterogeneity, resolution, and throughput. This new method, which the researchers have termed ‘capillary forming', promises a path to robust, deterministic fabrication of intricate structures with high mechanical stiffness.

The approach to capillary forming of CNTs starts with patterning a catalyst layer on a silicon wafer, using optical lithography. Second, that layer is used to grow microstructures made of vertically aligned CNTs - CNT forests - through thermal chemical vapor deposition (CVD) at atmospheric pressure. Next, a solvent such as acetone is condensed on the substrate. This is done by positioning the substrate, with the CNT patterns facing downward, over a container with the boiling solvent. The solvent vapor rises through the container and condenses on the substrate. Due to capillary rise, the solvent is drawn into each CNT microstructure independently. After the substrate has been exposed to the vapor for the desired duration, it is removed from the container. As a result of the process of infiltration and evaporation of the solvent liquid, capillary forces will bundle the CNTs, resulting in a transformation of the initial 2D geometries into intricate 3D structures.

With this method, it is possible to construct robust 3D assemblies of filamentary nanostructures. The researchers have demonstrated this method through the fabrication of a library of diverse CNT microarchitectures. A bending motion, for example, can be combined into twisting and bridge-shaped architectures which cannot be made using standard lithography. This new approach to manipulate nanoscale filaments using local mechanical deformations makes it easier to deterministically design and fabricate 3D microarchitectures with complex geometries as well as nanotextured surfaces. Yet it only requires a standard patterning and thermal processing at ambient pressure.

This work received the Robert M. Caddell award for outstanding research in materials and manufacturing.

Michael De Volder, Sameh H. Tawfick, Sei Jin Park, Davor Copic, Zhouzhou Zhao, Wei Lu, A. John Hart, "Diverse 3D Microarchitectures Made by Capillary Forming of Carbon Nanotubes", Advanced Materials Volume 22, Issue 39, pages 4384-4389, October 15, 2010.

####

For more information, please click here

Contacts:

Imec:

Katrien Marent

Director of External Communications

T: +32 16 28 18 80

M: +32 474 30 28 66

For Imec:

Barbara Kalkis

Maestro Marketing & PR

T: +1 408 996 9975

M: +1 408 529 4210

Copyright © imec

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Academic/Education

![]() Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

![]() Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Nanomedicine

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

![]() Researchers develop artificial building blocks of life March 8th, 2024

Researchers develop artificial building blocks of life March 8th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Grants/Sponsored Research/Awards/Scholarships/Gifts/Contests/Honors/Records

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Nanobiotechnology

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

![]() Researchers develop artificial building blocks of life March 8th, 2024

Researchers develop artificial building blocks of life March 8th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||