Home > Press > Energy Harvesting: Nanogenerators Grow Strong Enough to Power Small Conventional Electronic Devices

|

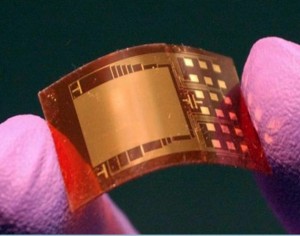

| In a new technique for producing nanogenerators, researchers transfer vertically-aligned nanowires to a flexible substrate. (Courtesy of Zhong Lin Wang) |

Abstract:

Blinking numbers on a liquid-crystal display (LCD) often indicate that a device's clock needs resetting. But in the laboratory of Zhong Lin Wang at Georgia Tech, the blinking number on a small LCD signals the success of a five-year effort to power conventional electronic devices with nanoscale generators that harvest mechanical energy from the environment using an array of tiny nanowires.

Energy Harvesting: Nanogenerators Grow Strong Enough to Power Small Conventional Electronic Devices

Atlanta, GA | Posted on November 9th, 2010In this case, the mechanical energy comes from compressing a nanogenerator between two fingers, but it could also come from a heartbeat, the pounding of a hiker's shoe on a trail, the rustling of a shirt, or the vibration of a heavy machine. While these nanogenerators will never produce large amounts of electricity for conventional purposes, they could be used to power nanoscale and microscale devices - and even to recharge pacemakers or iPods.

Wang's nanogenerators rely on the piezoelectric effect seen in crystalline materials such as zinc oxide, in which an electric charge potential is created when structures made from the material are flexed or compressed. By capturing and combining the charges from millions of these nanoscale zinc oxide wires, Wang and his research team can produce as much as three volts - and up to 300 nanoamps.

"By simplifying our design, making it more robust and integrating the contributions from many more nanowires, we have successfully boosted the output of our nanogenerator enough to drive devices such as commercial liquid-crystal displays, light-emitting diodes and laser diodes," said Wang, a Regents' professor in Georgia Tech's School of Materials Science and Engineering. "If we can sustain this rate of improvement, we will reach some true applications in healthcare devices, personal electronics, or environmental monitoring."

Recent improvements in the nanogenerators, including a simpler fabrication technique, were reported online last week in the journal Nano Letters. Earlier papers in the same journal and in Nature Communications reported other advances for the work, which has been supported by the Defense Advanced Research Projects Agency (DARPA), the U.S. Department of Energy, the U.S. Air Force, and the National Science Foundation.

"We are interested in very small devices that can be used in applications such as health care, environmental monitoring and personal electronics," said Wang. "How to power these devices is a critical issue."

The earliest zinc oxide nanogenerators used arrays of nanowires grown on a rigid substrate and topped with a metal electrode. Later versions embedded both ends of the nanowires in polymer and produced power by simple flexing. Regardless of the configuration, the devices required careful growth of the nanowire arrays and painstaking assembly.

In the latest paper, Wang and his group members Youfan Hu, Yan Zhang, Chen Xu, Guang Zhu and Zetang Li reported on much simpler fabrication techniques. First, they grew arrays of a new type of nanowire that has a conical shape. These wires were cut from their growth substrate and placed into an alcohol solution.

The solution containing the nanowires was then dripped onto a thin metal electrode and a sheet of flexible polymer film. After the alcohol was allowed to dry, another layer was created. Multiple nanowire/polymer layers were built up into a kind of composite, using a process that Wang believes could be scaled up to industrial production.

When flexed, these nanowire sandwiches - which are about two centimeters by 1.5 centimeters - generated enough power to drive a commercial display borrowed from a pocket calculator.

Wang says the nanogenerators are now close to producing enough current for a self-powered system that might monitor the environment for a toxic gas, for instance, then broadcast a warning. The system would include capacitors able to store up the small charges until enough power was available to send out a burst of data.

While even the current nanogenerator output remains below the level required for such devices as iPods or cardiac pacemakers, Wang believes those levels will be reached within three to five years. The current nanogenerator, he notes, is nearly 100 times more powerful than what his group had developed just a year ago.

Writing in a separate paper published in October in the journal Nature Communications, group members Sheng Xu, Benjamin J. Hansen and Wang reported on a new technique for fabricating piezoelectric nanowires from lead zirconate titanate - also known as PZT. The material is already used industrially, but is difficult to grow because it requires temperatures of 650 degrees Celsius.

In the paper, Wang's team reported the first chemical epitaxial growth of vertically-aligned single-crystal nanowire arrays of PZT on a variety of conductive and non-conductive substrates. They used a process known as hydrothermal decomposition, which took place at just 230 degrees Celsius.

With a rectifying circuit to convert alternating current to direct current, the researchers used the PZT nanogenerators to power a commercial laser diode, demonstrating an alternative materials system for Wang's nanogenerator family. "This allows us the flexibility of choosing the best material and process for the given need, although the performance of PZT is not as good as zinc oxide for power generation," he explained.

And in another paper published in Nano Letters, Wang and group members Guang Zhu, Rusen Yang and Sihong Wang reported on yet another advance boosting nanogenerator output. Their approach, called "scalable sweeping printing," includes a two-step process of (1) transferring vertically-aligned zinc oxide nanowires to a polymer receiving substrate to form horizontal arrays and (2) applying parallel strip electrodes to connect all of the nanowires together.

Using a single layer of this structure, the researchers produced an open-circuit voltage of 2.03 volts and a peak output power density of approximately 11 milliwatts per cubic centimeter.

"From when we got started in 2005 until today, we have dramatically improved the output of our nanogenerators," Wang noted. "We are within the range of what's needed. If we can drive these small components, I believe we will be able to power small systems in the near future. In the next five years, I hope to see this move into application."

####

For more information, please click here

Contacts:

Media Relations Assistance:

John Toon

404-894-6986

Abby Vogel Robinson

404-385-3364

Copyright © Georgia Tech

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Academic/Education

![]() Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

![]() Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Molecular Machines

![]() First electric nanomotor made from DNA material: Synthetic rotary motors at the nanoscale perform mechanical work July 22nd, 2022

First electric nanomotor made from DNA material: Synthetic rotary motors at the nanoscale perform mechanical work July 22nd, 2022

![]() Nanotech scientists create world's smallest origami bird March 17th, 2021

Nanotech scientists create world's smallest origami bird March 17th, 2021

![]() Giant nanomachine aids the immune system: Theoretical chemistry August 28th, 2020

Giant nanomachine aids the immune system: Theoretical chemistry August 28th, 2020

Nanomedicine

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

![]() Researchers develop artificial building blocks of life March 8th, 2024

Researchers develop artificial building blocks of life March 8th, 2024

Sensors

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Environment

![]() Billions of nanoplastics released when microwaving baby food containers: Exposure to plastic particles kills up to 75% of cultured kidney cells July 21st, 2023

Billions of nanoplastics released when microwaving baby food containers: Exposure to plastic particles kills up to 75% of cultured kidney cells July 21st, 2023

Energy

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||