Home > Press > Bayer MaterialScience and partners develop polyurethane nanofoams for thermal insulation

|

| polyurethane nanofoams |

Abstract:

Double the insulating performance, reduced energy consumption

Bayer MaterialScience and partners develop polyurethane nanofoams for thermal insulation

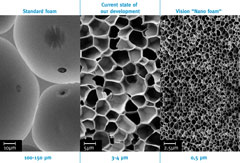

Leverkusen | Posted on October 15th, 2010Bayer MaterialScience is working on the development of polyurethane nanofoams that could lead to a quantum leap in thermal insulation performance several years down the road. The company is focusing its efforts on microemulsions, which react under supercritical conditions (Principle of Supercritical Microemulsion Expansion, POSME) to form polyurethane rigid foams. The aim is to produce rigid foams with pore sizes of less than 150 nanometers in diameter.

"Nanofoams of this kind achieve twice the thermal insulation performance of today's polyurethane foams, meaning that they could, for example, significantly reduce the energy consumption of refrigeration appliances and, in turn, make a major contribution to reducing CO2 emissions. Furthermore, the walls of these appliances could be of thinner design, resulting in more storage space for refrigerated goods," explained Dr. Stefan Lindner, a polyurethane rigid foam specialist at Bayer MaterialScience.

The company is partnering on this research project with Prof. Reinhard Strey from the University of Cologne's Institute of Physical Chemistry, who has applied for a patent on the POSME process. As part of the collaboration, his working group is engaged in optimizing the characteristics of the microemulsions.

The thermal insulation performance of a polyurethane rigid foam depends chiefly on the size of the foam pores. The smaller the diameter, the lower the thermal conductivity and the better the insulating effect. Today's polyurethane rigid foams typically have pore sizes of roughly 150 micrometers, which exceeds the pore size of nanofoams planned for the future by a factor of approximately 1,000.

To synthesize a nanofoam using the POSME method, carbon dioxide (CO2) and the liquid polyurethane raw materials (polyol and isocyanate) are mixed with the help of special surfactants at a pressure of 200 bar to form a microemulsion consisting of nanometer-sized droplets filled with CO2 and encapsulated in surfactants. The pressure is then reduced, causing the CO2 to expand and the droplets to become bubbles still in the nanometer range. At the same time, the polyurethane raw materials react to form a 3D polymer network that is a rigid polyurethane foam.

"One of the trickiest challenges we face is to optimally coordinate the reaction of the polyurethane raw materials with the expansion of the CO2 bubbles by carefully fine-tuning the processing parameters so that nanopores of the targeted diameter result," explained Mr. Lindner. "It's no easy task," added Dr. Wolfgang Friederichs, head of Global Product Research at Bayer MaterialScience. "It is likely to take several more years before these challenges are overcome."

####

About Bayer MaterialScience

With 2009 sales of EUR 7.5 billion, Bayer MaterialScience is among the world’s largest polymer companies. Business activities are focused on the manufacture of high-tech polymer materials and the development of innovative solutions for products used in many areas of daily life. The main segments served are the automotive, electrical and electronics, construction and the sports and leisure industries. At the end of 2009, Bayer MaterialScience had 30 production sites and employed approximately 14,300 people around the globe. Bayer MaterialScience is a Bayer Group company.

For more information, please click here

Copyright © Bayer MaterialScience

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Food/Agriculture/Supplements

![]() Silver nanoparticles: guaranteeing antimicrobial safe-tea November 17th, 2023

Silver nanoparticles: guaranteeing antimicrobial safe-tea November 17th, 2023

![]() Night-time radiative warming using the atmosphere November 17th, 2023

Night-time radiative warming using the atmosphere November 17th, 2023

![]() DGIST and New Life Group launched a research project on "Functional beauty and health products using the latest nanotechnology" May 12th, 2023

DGIST and New Life Group launched a research project on "Functional beauty and health products using the latest nanotechnology" May 12th, 2023

Energy

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

Home

![]() Nanomaterials enable dual-mode heating and cooling device: Device could cut HVAC energy use by nearly 20% in the US December 2nd, 2020

Nanomaterials enable dual-mode heating and cooling device: Device could cut HVAC energy use by nearly 20% in the US December 2nd, 2020

![]() Bosch Sensortec launches ideation community to foster and accelerate innovative IoT applications : Creativity hub for customers, partners, developers and makers February 18th, 2019

Bosch Sensortec launches ideation community to foster and accelerate innovative IoT applications : Creativity hub for customers, partners, developers and makers February 18th, 2019

![]() Iran Develops Water-Repellent Nano-Paint December 5th, 2018

Iran Develops Water-Repellent Nano-Paint December 5th, 2018

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||