Home > Press > Nanowick at heart of new system to cool 'power electronics'

|

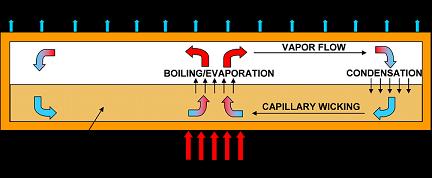

| This diagram depicts a cooling device called a heat pipe, used in electronics and computers. Researchers are developing an advanced type of heat pipe for high-power electronics in military and automotive systems. The system is capable of handling roughly 10 times the heat generated by conventional computer chips. The miniature, lightweight device uses tiny copper spheres and carbon nanotubes to passively wick a coolant toward hot electronics. (School of Mechanical Engineering, Purdue University) |

Abstract:

Researchers have shown that an advanced cooling technology being developed for high-power electronics in military and automotive systems is capable of handling roughly 10 times the heat generated by conventional computer chips.

Nanowick at heart of new system to cool 'power electronics'

West Lafayette, IN | Posted on July 26th, 2010The miniature, lightweight device uses tiny copper spheres and carbon nanotubes to passively wick a coolant toward hot electronics, said Suresh V. Garimella, the R. Eugene and Susie E. Goodson Distinguished Professor of Mechanical Engineering at Purdue University.

This wicking technology represents the heart of a new ultrathin "thermal ground plane," a flat, hollow plate containing water.

Similar "heat pipes" have been in use for more than two decades and are found in laptop computers. However, they are limited to cooling about 50 watts per square centimeter, which is good enough for standard computer chips but not for "power electronics" in military weapons systems and hybrid and electric vehicles, Garimella said.

The research team from Purdue, Thermacore Inc. and Georgia Tech Research Institute is led by Raytheon Co., creating the compact cooling technology in work funded by the Defense Advanced Research Projects Agency, or DARPA.

The team is working to create heat pipes about one-fifth the thickness of commercial heat pipes and covering a larger area than the conventional devices, allowing them to provide far greater heat dissipation.

New findings indicate the wicking system that makes the technology possible absorbs more than 550 watts per square centimeter, or about 10 times the heat generated by conventional chips. This is more than enough cooling capacity for the power-electronics applications, Garimella said.

The findings are detailed in a research paper appearing online this month in the International Journal of Heat and Mass Transfer and will be published in the journal's September issue. The paper was written by mechanical engineering doctoral student Justin Weibel, Garimella and Mark North, an engineer with Thermacore, a producer of commercial heat pipes located in Lancaster, Pa.

"We know the wicking part of the system is working well, so we now need to make sure the rest of the system works," North said.

The new type of cooling system can be used to prevent overheating of devices called insulated gate bipolar transistors, high-power switching transistors used in hybrid and electric vehicles. The chips are required to drive electric motors, switching large amounts of power from the battery pack to electrical coils needed to accelerate a vehicle from zero to 60 mph in 10 seconds or less.

Potential military applications include advanced systems such as radar, lasers and electronics in aircraft and vehicles. The chips used in the automotive and military applications generate 300 watts per square centimeter or more.

Researchers are studying the cooling system using a novel test facility developed by Weibel that mimics conditions inside a real heat pipe.

"The wick needs to be a good transporter of liquid but also a very good conductor of heat," Weibel said. "So the research focuses largely on determining how the thickness of the wick and size of copper particles affect the conduction of heat."

Computational models for the project were created by Garimella in collaboration with Jayathi Y. Murthy, a Purdue professor of mechanical engineering, and doctoral student Ram Ranjan. The carbon nanotubes were produced and studied at the university's Birck Nanotechnology Center in work led by mechanical engineering professor Timothy Fisher.

"We have validated the models against experiments, and we are conducting further experiments to more fully explore the results of simulations," Garimella said.

Inside the cooling system, water circulates as it is heated, boils and turns into a vapor in a component called the evaporator. The water then turns back to a liquid in another part of the heat pipe called the condenser.

The wick eliminates the need for a pump because it draws away fluid from the condenser side and transports it to the evaporator side of the flat device, Garimella said.

Allowing a liquid to boil dramatically increases how much heat can be removed compared to simply heating a liquid to temperatures below its boiling point. Understanding precisely how fluid boils in tiny pores and channels is helping the engineers improve such cooling systems.

The wicking part of the heat pipe is created by sintering, or fusing together tiny copper spheres with heat. Liquid is drawn sponge-like through spaces, or pores, between the copper particles by a phenomenon called capillary wicking. The smaller the pores, the greater the drawing power of the material, Garimella said.

Such sintered materials are used in commercial heat pipes, but the researchers are improving them by creating smaller pores and also by adding the carbon nanotubes.

"For high drawing power, you need small pores," Garimella said. "The problem is that if you make the pores very fine and densely spaced, the liquid faces a lot of frictional resistance and doesn't want to flow. So the permeability of the wick is also important."

The researchers are creating smaller pores by "nanostructuring" the material with carbon nanotubes, which have a diameter of about 50 nanometers, or billionths of a meter. However, carbon nanotubes are naturally hydrophobic, hindering their wicking ability, so they were coated with copper using a device called an electron beam evaporator.

"We have made great progress in understanding and designing the wick structures for this application and measuring their performance," said Garimella. He said that once ongoing efforts at packaging the new wicks into heat pipe systems that serve as the thermal ground plane are complete, devices based on the research could be in commercial use within a few years.

####

For more information, please click here

Contacts:

Writer:

Emil Venere

(765) 494-4709

Sources:

Suresh Garimella

(765) 494-5621

Justin Weibel

Copyright © Purdue University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Thin films

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

![]() New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Academic/Education

![]() Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

![]() Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Nanoelectronics

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

![]() Reduced power consumption in semiconductor devices September 23rd, 2022

Reduced power consumption in semiconductor devices September 23rd, 2022

![]() Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Military

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() New chip opens door to AI computing at light speed February 16th, 2024

New chip opens door to AI computing at light speed February 16th, 2024

Automotive/Transportation

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Research partnerships

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() 'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||