Home > Press > The thinnest, smoothest metallic lines in the world helps speed up miniaturisation of electronic devices

|

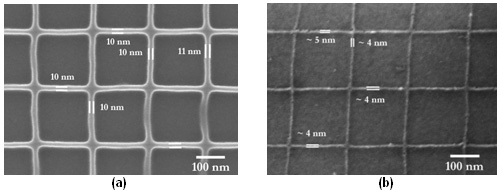

| Nanoscale lines of (a) copper naphthenate and (b) copper after hydrogen reduction showing size reduction by about 50%, to make the metal lines - the thinnest ever made to date. |

Abstract:

New method creates super-thin, high integrity, continuous metal lines that surpass today's semiconductor industry requirements.

The thinnest, smoothest metallic lines in the world helps speed up miniaturisation of electronic devices

Singapore | Posted on July 21st, 2010Scientists from Singapore A*STAR's Institute of Materials Research and Engineering (IMRE), University of Cambridge (UK) and Sungkyunkwan University (South Korea) have created metallic lines so thin and smooth that they can only be seen using powerful electron microscopes. This research will be published in the July issue of Advanced Functional Materials, the leading full-paper materials science journal.

At line widths of just 7 nm, their line width roughness, which are the variations in thickness along the line itself, stands at 2.9 nm, a value which is below the 2010 target of 3.2 nm and closer to 2011's target line width roughness of 2.8 nm indicated in the International Technology Roadmap for Semiconductors.

The ability to create such distinct lines and patterns on a sub-10 nm scale level is essential in the further miniaturisation of electronic components. Rough, undefined patterns and lines results in poorly made, energy-inefficient devices. The process is very delicate and precise because of the scale at which the work is done. For comparison, the width of the average human hair is 100 µm, which is about 14,000 times the width of a single 7 nm-wide metal line.

"Our thin, unbroken and smooth lines are important in ensuring the efficiency of ever shrinking electronic devices and may lead to more powerful processors. Furthermore, our work shows that continuous metallic lines as small as 4 nm are possible to make", says Dr MSM Saifullah, a Research Scientist with IMRE. The method could be potentially used to make interconnects, the ‘highways' that carry electrical pulses and data in extremely small integrated circuits (ICs). The smoother and uninterrupted ‘highways' lead to faster data transfer rates and less energy wasted, in the form of heat.

The novelty of the method was in the material and the technique that was used. The current "lift-off" approach for making metal lines at this scale requires more steps, uses more materials and results in rough, and quite often broken lines on a sub-10 nm scale. The researchers used an organometallic material which is made up of a metallic and an organic component. Using a combination of electron beam lithography and subsequent gas treatment, the researchers were able to easily chip away the organic portions in a uniform manner, leaving the desired metallic patterns, in this case, thin metal lines.

"The published results is a testament to the cutting-edge nanotechnology research that is done in Singapore, where we push, and sometimes lead, the rest of the world", says Prof Andy Hor, IMRE's new Executive Director, who took the helm of Singapore's materials research institute in June 2010.

"Our obvious expertise in the area of nanopatterning is also a reason why we are driving a concerted effort for the industry to adopt technologies such as this into their manufacturing processes", explains Prof Hor. IMRE will be launching an Industrial Consortium on Nanoimprinting (ICON) on 3 August 2010 to encourage industry to take full advantage of the benefits that advanced nanopatterning has to offer.

The research on the metal lines will be featured on the inside front cover of Issue 14 (July 2010) of the Advanced Functional Materials journal.

####

About A*STAR

The Agency for Science, Technology and Research (A*STAR) is the lead agency for fostering world-class scientific research and talent for a vibrant knowledge-based and innovation-driven Singapore. A*STAR oversees 14 biomedical sciences, and physical sciences and engineering research institutes, and seven consortia & centres, which are located in Biopolis and Fusionopolis, as well as their immediate vicinity.

A*STAR supports Singapore's key economic clusters by providing intellectual, human and industrial capital to its partners in industry. It also supports extramural research in the universities, hospitals, research centres, and with other local and international partners.

About the Institute of Materials Research and Engineering (IMRE)

Established in September 1997, IMRE has built strong capabilities in materials analysis, characterisation, materials growth, patterning, fabrication, synthesis and integration. IMRE is an institute of talented researchers equipped with state-of-the-art facilities such as the SERC Nanofabrication and Characterisation Facility to conduct world-class materials science research. Leveraging on these capabilities, R&D programmes have been established in collaboration with industry partners. These include research on organic solar cells, nanocomposites, flexible organic light-emitting diodes (OLEDs), solid-state lighting, nanoimprinting, microfluidics and next generation atomic scale interconnect technology.

For more information about IMRE, please visit www.imre.a-star.edu.sg

For more information, please click here

Contacts:

For media enquiries, please contact:

Mr Eugene Low

Manager, Corporate Communications

for Institute of Materials Research and Engineering (IMRE)

3, Research Link

Singapore 117602

DID +65 6874 8491

Mobile +65 9230 9235

For technical and business enquiries, please contact:

Dr MSM Saifullah

Research Scientist

Institute of Materials Research and Engineering (IMRE)

3, Research Link

Singapore 117602

DID +65 6874 1484

Mr Rick Ong

Industry Development Manager

Institute of Materials Research and Engineering (IMRE)

3, Research Link

Singapore 117602

DID +65 6513 1198

Copyright © A*STAR

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Academic/Education

![]() Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

![]() Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Nanoelectronics

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

![]() Reduced power consumption in semiconductor devices September 23rd, 2022

Reduced power consumption in semiconductor devices September 23rd, 2022

![]() Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Research partnerships

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() 'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||