Home > Press > NREL, 3M Launch Technology Partnership

|

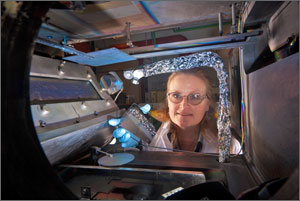

| NREL Principal Investigator Cheryl Kennedy first helped develop reflective coatings for concentrated solar power with 3M when she joined the Laboratory in the 1980s. Credit: Pat Corkery |

Abstract:

The U.S. Department of Energy's National Renewable Energy Laboratory and 3M, the St. Paul, Minn.-based technology company, have embarked on research and development partnerships in three key areas of clean energy innovation: thin-film photovoltaics, concentrating solar power and biofuels.

By Joe Verrengia

NREL, 3M Launch Technology Partnership

Washington, DC | Posted on May 20th, 2010The work ranges from jointly identifying and developing critical aspects of renewable energy technology to accelerated testing of 3M designs and scaling-up successful prototypes for commercial production. The partnerships are covered in three Cooperative Research and Development Agreements, or CRADAs, which last for at least one year. The total combined value of the shared R&D covered by the agreements is $7.33 million.

With $23 billion in annual sales, 3M employs 75,000 people worldwide and has operations in more than 65 countries. It is one of the Laboratory's largest commercial partners.

"CRADAs like these with 3M are critical for achieving the marketplace impact that is the goal of NREL's work in renewable energy," NREL Senior Vice President of Commercialization and Deployment Casey Porto said. "Not only do they help shift the nation to clean energy, but they also establish and expand important partnerships for product development through technology transfer."

"3M's wide-ranging expertise and commitment in these fields makes this a key partnership for the laboratory because this type of partnership enables the creation of clean energy breakthroughs that can become products," she said.

"3M is excited for the opportunity to tap into NREL's expertise and understanding of a variety of solar modules and the interplay between the materials and systems," said Mike Roman, general manager and vice president of 3M Renewable Energy Division. "Also, NREL has pilot plant capabilities, which allow valuable application testing of 3M's biofuel separations technologies in a controllable and scalable environment."

Thin Film Solar Cells

3M and NREL will work to develop and test new moisture barrier films and flexible packaging for thin film solar cells made of semiconducting layers of CIGS, or Copper Indium Gallium Diselenide.

CIGS cells have achieved a record efficiency of 19.9 percent at NREL. But to become commercially successful, manufacturers need to both increase module performance and reduce manufacturing costs.

The solar cells are expected to work effectively for 20 years. That means they will need to be encapsulated in a flexible material that is transparent to light, but also provides durable protection — and doesn't add significant costs.

NREL will conduct accelerated stress tests, including temperature, humidity and irradiance tests, to establish failure barriers on as many as three types of 3M CIGS designs. The Lab and 3M will jointly interpret the results with the aim of establishing module standards for a 20-year lifetime.

Principal investigator Mike Kempe said much of the testing will revolve around measuring the rate of water vapor transmission in moisture barrier samples.

"We test their moisture barrier materials to determine if they give adequate protection to the CIGS cells," Kempe said. "They want expert eyes looking at these materials before they go to the PV industry."

Concentrating Solar Power

3M is developing highly reflective silvered polymer mirror reflectors as low-cost replacements for glass mirrors in Concentrating Solar Power (CSP) systems. Investors want solar reflectors that are as durable as glass and that meet increasing performance standards.

It's work that started 25 years ago with a 3M reflective coating known as ECP305+, Principal investigator Cheryl Kennedy was new to the Laboratory's CSP staff when she shared a patent on the reflective coating.

Today 3M is working with Kennedy again to develop a new version of the solar mirror film. The original solar mirror film was supposed to work reliably for 10 years, but in field tests it is still maintaining its reflectance after at least 15 years of outdoor exposure.

In a second related effort, 3M and NREL will develop a durable, cleanable hard-coat surface for the top layer of the metalized polymeric mirror films.

"At first people thought coatings to prevent CSP mirrors from getting dirty was too futuristic," Kennedy said. "Now the CSP market is taking off. They are looking for coatings that will help mirrors remain highly reflective for 30-50 years with minimal scratching and cleaning. That's how long a coal-fired power plant stays online generating electricity, so CSP systems need low-cost mirrors that maintain high specular reflectance for extended lifetimes outdoors in order to be competitive."

In a third related effort, 3M and NREL will test the new polymeric mirror films and compare the performance using a service lifetime model first developed with the original ECP-305+ reflector. NREL will characterize the new film's optical performance and durability by conducting tests in accelerated weathering chambers that use xenon arc lamps to simulate extreme and accelerated conditions of light, temperature and humidity at about seven times typical outdoor exposure.

Additionally, samples will be exposed in a new UV concentrator, which has the capability of concentrating natural sunlight 100 times in the UV portion of the solar spectrum. Samples will be exposed for the equivalent of 1 year of concentrated UV exposure with temperature and humidity control.

Ethanol-Biofuels

A new 3M prototype liquid-liquid separations technology uses a membrane to significantly increase the concentration of ethanol extracted from a fermentation broth. The new method does not rely on heat to evaporate water in the broth and reduces the distillation energy required to separate water and ethanol.

3M wants to test and scale-up the new technology for both the existing conventional corn-based ethanol industry and for the emerging lignocellulosic ethanol industry, which produces ethanol from the tougher parts of plants — like stalks, cobs and leaves — that are not part of the food supply.

Archer-Daniels Midland is the among the largest U.S. corn ethanol producers, and will test the 3M prototype in one of its pilot plants.

"The membrane technology has to be cheaper than the standard distillation method of recovering ethanol," said principal investigator Dan Schell. "We're trying to be more aware of separation as a unique step in the process and take advantage of it."

####

About National Renewable Energy Laboratory

NREL is the only federal laboratory dedicated to the research, development, commercialization and deployment of renewable energy and energy efficiency technologies. Backed by 32 years of achievement, NREL leads the way in helping meet the growing demand for clean energy.

For more information, please click here

Copyright © National Renewable Energy Laboratory

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Thin films

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

![]() New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

![]() Thin-film, high-frequency antenna array offers new flexibility for wireless communications November 5th, 2021

Thin-film, high-frequency antenna array offers new flexibility for wireless communications November 5th, 2021

Jobs

![]() Could quantum technology be New Mexico’s next economic boon? Quantum New Mexico Coalition aims to establish state as national hub April 1st, 2022

Could quantum technology be New Mexico’s next economic boon? Quantum New Mexico Coalition aims to establish state as national hub April 1st, 2022

![]() SEMI Partners with GLOBALFOUNDRIES to Offer Apprenticeship Program Aimed at Building the Electronics Talent Pipeline August 11th, 2020

SEMI Partners with GLOBALFOUNDRIES to Offer Apprenticeship Program Aimed at Building the Electronics Talent Pipeline August 11th, 2020

![]() Arrowhead Pharmaceuticals Reports Inducement Grants under NASDAQ Marketplace Rule 5635(c)(4) March 29th, 2019

Arrowhead Pharmaceuticals Reports Inducement Grants under NASDAQ Marketplace Rule 5635(c)(4) March 29th, 2019

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Energy

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

Alliances/Trade associations/Partnerships/Distributorships

![]() Chicago Quantum Exchange welcomes six new partners highlighting quantum technology solutions, from Chicago and beyond September 23rd, 2022

Chicago Quantum Exchange welcomes six new partners highlighting quantum technology solutions, from Chicago and beyond September 23rd, 2022

![]() University of Illinois Chicago joins Brookhaven Lab's Quantum Center June 10th, 2022

University of Illinois Chicago joins Brookhaven Lab's Quantum Center June 10th, 2022

Research partnerships

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() 'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

Solar/Photovoltaic

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||