Home > Press > Printed Origami Offers New Technique For Small, Complex Structures

|

Abstract:

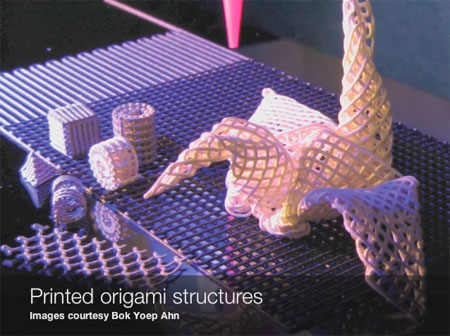

Although it looks small and unassuming, the tiny origami crane sitting in a sample dish in University of Illinois professor Jennifer Lewis' lab heralds a new method for creating complex three-dimensional structures for biocompatible devices, microscaffolding and other microsystems. The penny-sized titanium bird began as a printed sheet of titanium hydride ink.

The team will publish their novel technique in the April 14 online edition of the journal Advanced Materials.

Printed Origami Offers New Technique For Small, Complex Structures

Champaign, IL | Posted on April 14th, 2010Small, intricate shapes made of metals, ceramics or polymers have a variety of applications, from biomedical devices to electronics to rapid prototyping. One method of fabricating such structures is by direct-write assembly, which the Lewis group helped pioneer. In this approach, a large printer deposits inks containing metallic, ceramic or plastic particles to assemble a structure layer by layer. Then, the structure is annealed at a high temperature to evaporate the liquid in the ink and bond the particles, leaving a solid object.

However, as more layers are added, the lower layers tend to sag or collapse under their own weight - a problem postdoctoral researcher Bok Yeop Ahn encountered while trying to manufacture titanium scaffolds for tissue engineering. He decided to try a different approach: Print a flat sheet, then roll it up into a spiral - or even fold it into an assortment of shapes.

Folding the printed sheets is not as easy as it would first seem.

"Most of our inks are based on aqueous formulations, so they dry quickly. They become very stiff and can crack when folded," said Lewis, the Thurnauer Professor of Materials Science and Engineering and the director of the university's Frederick Seitz Materials Research Laboratory. The challenge, then, was to find a solution that would render the printed sheets pliable enough to manipulate yet firm enough to retain their shape after folding and during annealing.

Lewis, Ahn and their research team solved the problem by mimicking wet-folding origami, in which paper is partially wetted to enhance its foldability. By using a mixture of fast-drying and slow-drying solvents in the ink, the sheet dries partway but stays flexible enough to fold through multiple steps - 15, in the case of the crane.

The U. of I. researchers worked with professor David Dunand, the James and Margie Krebs Professor of Materials Science at Northwestern University, who initially approached Lewis with the possibility of titanium hydride inks. "I knew how to transform hydride into metallic titanium without contamination from the ink, based on prior research in my lab," said Dunand, who focused on annealing the soft, titanium hydride origami structures into strong, metallic titanium objects.

The marriage of printing and origami techniques allows for greater structural complexity - such as the crane's overhanging wings, a feature not producible by direct printing methods alone. In addition, Lewis' team can print sheets with a variety of patterns, adding yet another level of architectural detail.

"By combining these methods, you can rapidly assemble very complex structures that simply cannot be made by conventional fabrication methods," Lewis said.

Next, the team hopes to expand its origami repertoire to include much larger and much smaller structures, with an expanding array of inks. For example, the method can be extended to a variety of other ceramics and metals ranging from steels to nickel- and cobalt-based alloys to refractory and noble metals, according to Dunand.

The researchers also plan to explore possible applications including lightweight structures, biomedical devices, sensors and more.

"We've really just begun to unleash the power of this approach," Lewis said.

The Department of Energy-sponsored U. of I. team also included graduate student Christopher Hansen, and visiting scientist Daisuke Shoji, of the Pentax-Hoya Corp., Tokyo. The NSF-sponsored Northwestern team included undergraduate student Eunji Hong (visiting from Kookmin University, Seoul).

Editor's note: To reach Jennifer Lewis, call 217-244-4973; e-mail

See a video of a variety of the structures: www.news.illinois.edu/videos/0412origami.html

####

About University of Illinois at Urbana-Champaign

We serve the state, the nation, and the world by creating knowledge, preparing students for lives of impact, and addressing critical societal needs through the transfer and application of knowledge.

For more information, please click here

Contacts:

Liz Ahlberg

Physical Sciences Editor

217-244-1073

Copyright © University of Illinois at Urbana-Champaign

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Academic/Education

![]() Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

![]() Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||