Home > Press > Energy-harvesting rubber sheets could power pacemakers, mobile phones

|

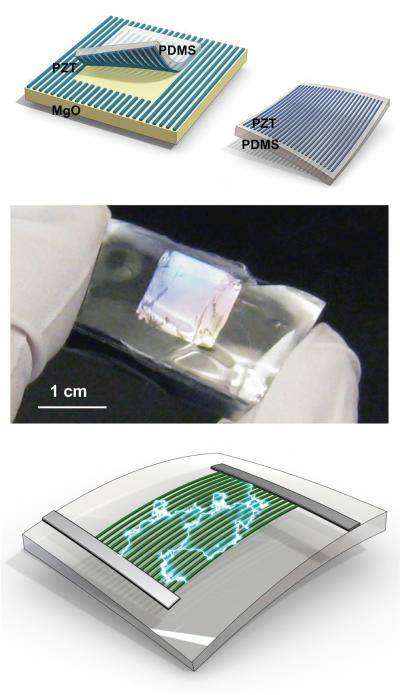

| The top image shows the process piezoelectric nanoribbons are peeled off a host substrate and placed onto rubber. The middle image is a photograph of the piezo-rubber chip. The bottom image is a schematic of the energy harvesting circuit, which generates power when it's bent. Credit: Courtesy Michael McAlpine/Princeton University |

Abstract:

Power-generating rubber films developed by Princeton University engineers could harness natural body movements such as breathing and walking to power pacemakers, mobile phones and other electronic devices.

Energy-harvesting rubber sheets could power pacemakers, mobile phones

Princeton, NJ | Posted on January 29th, 2010The material, composed of ceramic nanoribbons embedded onto silicone rubber sheets, generates electricity when flexed and is highly efficient at converting mechanical energy to electrical energy. Shoes made of the material may one day harvest the pounding of walking and running to power mobile electrical devices. Placed against the lungs, sheets of the material could use breathing motions to power pacemakers, obviating the current need for surgical replacement of the batteries which power the devices.

A paper on the new material, titled "Piezoelectric Ribbons Printed onto Rubber for Flexible Energy Conversion," was published online Jan. 26, in Nano Letters, a journal of the American Chemical Society. The research was funded by the United States Intelligence Community, a cooperative of federal intelligence and national security agencies.

The Princeton team is the first to successfully combine silicone and nanoribbons of lead zirconate titanate (PZT), a ceramic material that is piezoelectric, meaning it generates an electrical voltage when pressure is applied to it. Of all piezoelectric materials, PZT is the most efficient, able to convert 80% of the mechanical energy applied to it into electrical energy.

"PZT is 100 times more efficient than quartz, another piezoelectric material," said Michael McAlpine, a professor of mechanical and aerospace engineering, at Princeton, who led the project. "You don't generate that much power from walking or breathing, so you want to harness it as efficiently as possible."

The researchers first fabricated PZT nanoribbons - strips so narrow that 100 fit side-by-side in a space of a millimeter. In a separate process, they embedded these ribbons into clear sheets of silicone rubber, creating what they call "piezo-rubber chips." Because the silicone is biocompatible, it is already used for cosmetic implants and medical devices. "The new electricity-harvesting devices could be implanted in the body to perpetually power medical devices, and the body wouldn't reject them," McAlpine said.

In addition to generating electricity when it is flexed, the opposite is true: the material flexes when electrical current is applied to it. This opens the door to other kinds of applications, such as use for microsurgical devices, McAlpine said.

"The beauty of this is that it's scalable," said Yi Qi, a postdoctoral researcher who works with McAlpine. "As we get better at making these chips, we'll be able to make larger and larger sheets of them that will harvest more energy."

Qi and McAlpine collaborated with Habib Ahmad of the California Institute of Technology along with Noah Jafferis, a Princeton graduate student in electrical engineering; Kenneth Lyons Jr., an undergraduate at Morehouse College who worked in McAlpine's lab; and Christine Lee, an undergraduate at Princeton.

Nano Letters Article: pubs.acs.org/doi/abs/10.1021/nl903377u

####

For more information, please click here

Contacts:

Chris Emery

609-258-4597

Copyright © Eurekalert

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Energy

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||