Home > Press > IBM Scientists Effectively Eliminate Wear at the Nanoscale

|

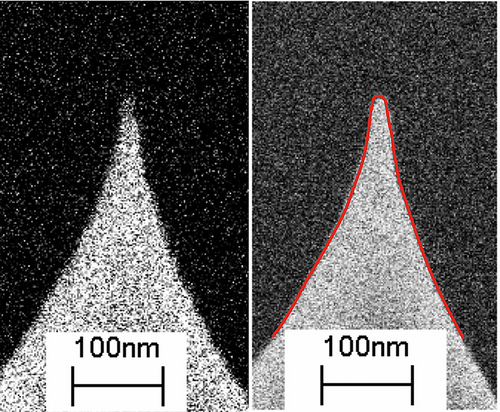

| Scanning electron micrograph showing no measurable mechanical wear in a vibrating nanotip sliding 750-meters over a polymer surface. The tip measures 500 nanometers in length and only 5 nanometers at its apex. On the left is the original tip, on the right the same tip after the 750-meter wear test. The red line shows the outline of the original tip shape overlayed on an image taken at the end of the experiment. The key to success: A small almost imperceptible vibration of the tip. Image courtesy of IBM Research - Zurich |

Abstract:

Results could lead to new high-precision and high-quality nanomechanical tools in nanofabrication and in the development of next-generations chips

IBM Scientists Effectively Eliminate Wear at the Nanoscale

Zurich, Switzerland | Posted on September 8th, 2009IBM (NYSE: IBM) scientists have demonstrated a promising and practical method that effectively eliminates the mechanical wear in the nanometer-sharp tips used in scanning probe-based techniques. This discovery can potentially be used in the development of next generation, more advanced computer chips that have higher performance and smaller feature sizes. Scanning probe-based tools could be one approach to extend the capabilities, quality and precision beyond the projected limits of current production and characterization tools.

Scanning probe-based techniques utilize tiny, nanometer-sharp tips borrowed from atomic force microscopy to manipulate nanostructures and devices by scanning or rather sliding in very close proximity over the surface—similar to the way the needle of a record player on a record. Today, these techniques—including for example the well-known atomic force microscope—are established tools for scientists to explore the nanocosmos. Scanning-probe techniques today allow for the highest possible resolution down to the atomic or molecular scale and represent essentially the scientists' "eyes", "ears", "nose", and "hands" as they explore the smallest objects known to mankind.

In the semiconductor industry, these techniques due to their atomic resolution and manipulation capabilities become increasingly attractive for use in the development and manufacturing of next generation chips with ultra-small feature sizes. While small by most standards, today's 40 nm transistors can still shrink further, but it becomes increasingly challenging and costly since the current tools and methods to develop and process the chips out of silicon wafers approach physical limitations for critical chip layers.

"Continued scaling to further increase device performance will require new device architectures, smaller feature sizes and new materials. Tools based on scanning probe technology could become essential for the metrology of future technology nodes as well as for the development, fabrication and characterization of novel nanoscale devices," says IBM Fellow Evangelos Eleftheriou of IBM Research - Zurich.

A key limiting factor for the prospects of large-scale industrial uses of such techniques, however, has been mechanical wear of the sharp tips. Wear resulting from friction between moving parts are inherent to all mechanical processes on the macro- as well as on the nanometer-scale. However, for scanning probe-based technologies, which rely on a nanometer-sharp tip—measuring just five nanometers at its apex—this problem is accentuated. A few cubic nanometers more or less can ruin the sensitivity of the tip. "In future industrial applications such as large area characterization of the features on a silicon wafer, a tip would need to be able to slide tens of kilometers or miles without replacement," explains IBM scientist Mark Lantz. In the currently used scanning modes, the tip wears out after a few meters or yards. "Moreover, in addition to causing wear of the tip, friction can potentially also do damage to the surface being characterized."

In their paper, published in the September issue of Nature Nanotechnology, IBM scientists solve this challenge by "demonstrating the effective elimination of wear on a tip sliding on a polymer surface over a distance of 750 meters by modulating the force acting on the tip-sample contact." By applying an AC voltage between the cantilever—the mechanical arms on which the tips are attached and over which they are controlled—and the sample surface, the cantilever can be excited at high frequencies of one Megahertz. The cantilever bends and the tip vibrates with an almost imperceptible estimated amplitude of one nanometer. "Though vanishingly small, it is this vibration that greatly reduces friction and "effectively" eliminates—to below the detection limit corresponding to the remarkable low number of losing one atom per meter—tip wear under experimental conditions," states Bernd Gotsmann of IBM Research - Zurich. After the 750-meter wear test, which took a week of continuous operation, the tip was still operating flawlessly.

With the wear problem tackled, researchers at IBM Research - Zurich are now investigating a number of possible applications of scanning probe-based technologies including nanofabrication, nanolithography and high-speed metrology. Operating a large number of tips in parallel would enable, high-throughput, high-speed, automated metrology systems for potential use in chip development and manufacturing. Such metrology systems could characterize device dimensions or identify defects on the structured silicon wafers with much higher precision and accuracy and potentially lower cost than currently available tools. Scientists at IBM Research - Zurich are also investigating powerful scanning probe-based method for high speed patterning of complex two and three-dimensional nanoscale structures.

The scientific paper entitled "Dynamic Superlubricity and the Elimination of Wear on the Nanoscale" by M.A. Lantz, D. Wiesmann, and B. Gotsmann, is published in Nature Nanotechnology, Volume 4, Issue 9 (September 2009).

####

For more information, please click here

Contacts:

Nicole Herfurth

Media Relations

IBM Research GmbH

IBM Research - Zurich

Säumerstrasse 4

8803 Rüschlikon

Switzerland

Tel +41 44 724 8445

Fax +41 44 724 8952

Copyright © http://www.zurich.ibm.com

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Nanoelectronics

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

![]() Reduced power consumption in semiconductor devices September 23rd, 2022

Reduced power consumption in semiconductor devices September 23rd, 2022

![]() Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Tools

![]() Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

![]() The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||