Home > Press > Self-healing surfaces

|

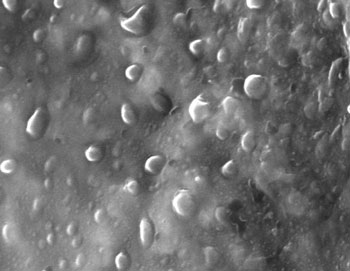

| The nano-capsules in the electroplated layer contain a fluid. If the layer is scratched, the layer bursts, the fluid escapes and repairs the scratch. (copyright Fraunhofer IPA) |

Abstract:

The engineers‘ dream of self-healing surfaces has taken another step towards becoming reality - researchers have produced a electroplated layer that contains tiny nanometer-sized capsules. If the layer is damaged, the capsules release fluid and repair the scratch.

Self-healing surfaces

Munich, Germany | Posted on August 3rd, 2009Human skin is a phenomenon - small scratches and cuts heal quickly, leaving no trace of a scar after just a few days. It's a different matter with materials, such as metals - if the electroplated layer protecting the metals from corrosion is scratched, rust protection is lost.

Engineers are working on transferring the self-healing effect of skin to materials. The idea behind this is to introduce evenly distributed fluid-filled capsules into the electroplated layer - rather like raisins in a cake. If the layer is damaged, the pellets at the point of damage burst, the fluid runs out and ‘repairs' the scratch. Until now, these plans have failed due to the size of the capsules - at 10 to 15 micrometers they were too large for the electroplated layer, which is around 20 micrometers thick. The capsules altered the mechanical properties of the layer.

Researchers from the Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Stuttgart, together with colleagues from Duisburg-Essen University, have developed a process for producing electroplated layers with nano-capsules, in a project being financed by the Volkswagen Foundation. At only a few hundred nanometers in diameter, the capsules are measured on another scale entirely, compared with previous results. "The challenge lies in not damaging the capsules when producing the electroplated layer", says Dr. Martin Metzner, Head of Department at IPA. "The smaller the capsules, the thinner and more sensitive their casing. The electrolytes used for these electroplated-technical processes are extremely aggressive chemically and can easily destroy the capsules". The researchers therefore had to find a compatible material for the capsule casing depending on the electrolytes used.

Mechanical bearings are one example of possible applications - the materials of the bearings usually have a electroplated coating, in which the capsules can be embedded. If there is a temporary shortage of lubricant, part of the bearing's coating is lost, the capsules at the top of the layer burst and release lubricant. The bearing is not therefore damaged if it temporarily runs dry. The researchers have produced the first copper, nickel and zinc coatings with the new capsules, although surface coverage does not extend beyond the centimeter scale. Experts estimate that it will be another one and a half to two years before whole components can be coated. In a further step the team worked on more complex systems - involving differently filled capsules, for example, whose fluids react with one another like a two component adhesive.

####

About Fraunhofer Society

The Fraunhofer-Gesellschaft promotes and undertakes applied research in an international context, of direct utility to private and public enterprise and of wide benefit to society as a whole.

By developing technological innovations and novel systems solutions for their customers, the Fraunhofer Institutes help to reinforce the competitive strength of the economy in their region, throughout Germany and in Europe. Their research activities are aimed at promoting the economic development of our industrial society, with particular regard for social welfare and environmental compatibility.

As an employer, the Fraunhofer-Gesellschaft offers a platform that enables its staff to develop the necessary professional and personal skills that will enable them to assume positions of responsibility within their institute, in industry and in other scientific domains.

For more information, please click here

Contacts:

Dr.-Ing. Martin Metzner

Fraunhofer-Institut für Produktionstechnik und Automatisierung

Copyright © Fraunhofer-Institut für Produktionstechnik und Automatisieru

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Automotive/Transportation

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||