Home > Press > World record: 400 W femtosecond laser for ultra-precise materials processing

|

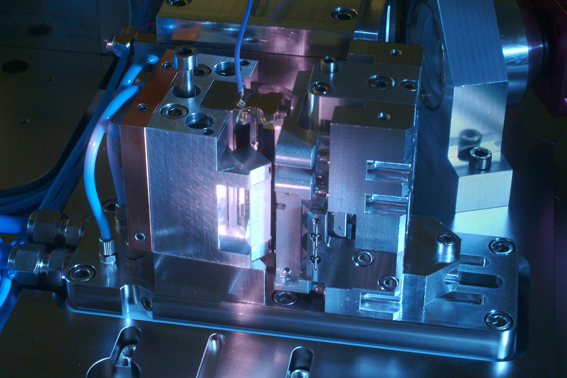

| World record: 400 W femtosecond laser developed by the Fraunhofer ILT for ultra-precise materials processing Picture source: Fraunhofer Institute for Laser Technology ILT, Aachen |

Abstract:

Femtosecond lasers (fs-lasers) are the key to ultra-precision processing. Whether in medicine, electronics, aerospace or solar technology, thin coatings can be removed, fiber-reinforced plastics drilled and ceramic components' surfaces structured using fs-lasers. Wider use of fs-lasers, however, is hampered by the average output which is currently limited to below 100 W on commercial systems. At the LASER World of Photonics 2009 in Munich the Fraunhofer Institute for Laser Technology ILT will show for the first time the currently most powerful ultra-short-pulse laser module with an output of over 400 watts and pulse durations of less than 1 ps.

World record: 400 W femtosecond laser for ultra-precise materials processing

Munich, Germany | Posted on May 12th, 2009Femtosecond (fs) lasers, i.e. lasers with pulse durations of less than one picosecond, have experienced a stormy development on the scientific front since their beginnings 35 years ago. The interaction of fs-laser radiation with material is characterized by the fact that the pulse duration is shorter than most interaction times between atoms or atoms and electrons. Thus, when material is processed, heat conduction, melting, evaporation and plasma formation only take place after the impact of the laser radiation. In contrast to longer nanosecond pulses or continuous wave (cw) lasers, no direct interaction of light and diffusing material takes place, which facilitates high-precision material removal. With fs-lasers it is therefore possible to achieve processing results which cannot be matched by any other method.

A major obstacle to the widespread use of present fs-lasers, however, is their average output power. Whereas cw-fiber and disk lasers nowadays reach an average output of a kilo-watt and more with diffraction-limited beam quality, the output power of fs-lasers is typically in the range of a single watt. 50-watt lasers are regarded as the high-end range for commercial lasers. Owing to their complex design, the price for such systems is a few hundred thousand euros. The high price and output-limited processing speed are therefore restricting the present potential of fs-lasers. Up to now they have not been widely embraced in production.

At the LASER World of Photonics 2009 the Fraunhofer ILT is unveiling the currently most powerful ultra-short-pulse laser module. This was developed in part under the LASERTRON (FKZ 13N8720) joint project with funding from the German Ministry of Education and Research (BMBF) under the FEMTONIK program. With an average output of more than 400 watts, it holds the world record for average output among lasers with pulse durations of less than one picosecond.

This was made possible by reinterpreting the InnoSlab technology which has been under development at the Fraun-hofer Institute for Laser Technology (ILT) for more than 10 years. This technology already forms the basis for numerous nano- and picosecond laser systems in industrial use. The extremely simple construction of the single-pass amplifier with four mirrors and one laser crystal permits an opto-mechanically and thermally robust and compact design.

In addition, a reduction and adaptation of the intensities arising is concept-inherent and makes it possible to reach pulse energies below one millijoule - which are relevant in particular for micro materials processing - without the need for complex chirped pulse amplification (CPA). This represents a further breakthrough for the simplification of fs-laser systems and the costs they entail, which is a key requirement for their widespread use in industrial practice.

The innovative laser from the Fraunhofer ILT is characterized by the fact that the oscillators with an output power of 1-2 watts can be amplified up to 400 watts by means of a single amplifier stage. At full output, a beam quality of M2<1.4 and an optical efficiency of 50% are attained. The almost diffraction-limited beam quality permits transformation into a round beam over the entire propagation range, which is frequently required for applications.

Further highlights include pulse durations below 700 fs and spectral bandwidths below 2 nm. The pulses are therefore distinctly shorter than on present ps-lasers and produce better results, for example in micro materials processing. Also, the bandwidth and wavelength unrestrictedly permit the use of the same optics as on typical ps and ns lasers. Special attachments for time compression (compressors), as frequently necessary on ultra-short-pulse lasers, are no longer required. The problems which can be caused by these attachments, such as pulse front / phase front tilt, therefore do not arise.

Given the bandwidth-limited spectrum and the high pulse peak output power, the laser radiation is very suitable for non-linear frequency conversion. Ongoing tasks include frequency doubling, compression of the pulse duration and production of high harmonics. Use in the scientific field will be made possible in future by increasing the pulse energy to the multi 10mJ range at several 100 watts of average output using additional CPA.

According to all the theoretical and experimental findings, the practical limits of the ultra-short-pulse laser have not yet been reached. The Fraunhofer ILT is therefore already working on scaling the innovative fs-laser to outputs of greater than 1000 watts. The results of the new technology will be presented to a broad specialist public at the joint Fraunhofer stand in Hall C2 at LASER 2009 in Munich from June 15 to 18, 2009.

####

For more information, please click here

Contacts:

Fraunhofer Institute for Laser Technology ILT

Steinbachstr. 15

D-52074 Aachen

Germany

Phone +49 241 8906-0

Fax +49 241 8906-121

email

Copyright © Fraunhofer

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Events/Classes

![]() Researchers demonstrate co-propagation of quantum and classical signals: Study shows that quantum encryption can be implemented in existing fiber networks January 20th, 2023

Researchers demonstrate co-propagation of quantum and classical signals: Study shows that quantum encryption can be implemented in existing fiber networks January 20th, 2023

Photonics/Optics/Lasers

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Optically trapped quantum droplets of light can bind together to form macroscopic complexes March 8th, 2024

Optically trapped quantum droplets of light can bind together to form macroscopic complexes March 8th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||