Home > Press > IMEC reports record power for micromachined piezoelectric energy harvester

|

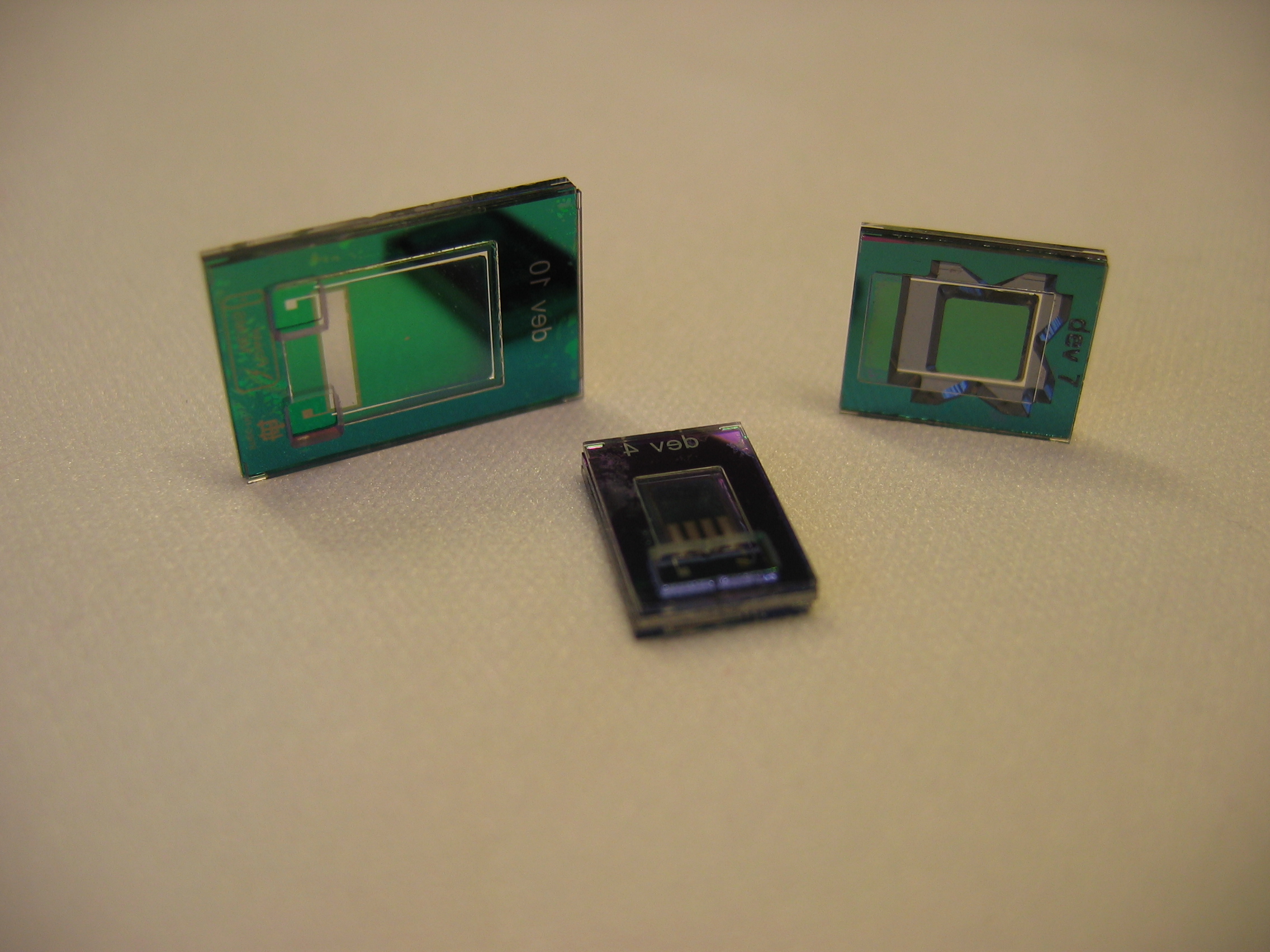

| Piezoelectric energy harvesters. |

Abstract:

In the framework of Holst Centre, IMEC achieved a new record for micromachined piezoelectric energy harvesters, now delivering an output power of 60µW. The harvester can be realized with a simple, low-cost CMOS-compatible production process by using aluminum nitride (AlN) as piezoelectric material. The low resonance frequency of only 500Hz makes the device widely applicable. The output power of 60µW is sufficient to drive simple wireless sensors that intermittently transfer sensor readings to a master. Potential applications include tire pressure monitoring systems (TPMS) or monitoring of industrial equipment.

IMEC reports record power for micromachined piezoelectric energy harvester

Leuven, Belgium | Posted on October 14th, 2008Energy harvesters convert ambient energy - light, heat, or vibrations - into electricity. They are indispensible in situations where batteries cannot be replaced easily. Examples are autonomous sensor networks that are distributed over large areas and in locations that are difficult to access. IMEC's new energy harvester is a micromachined device converting vibration energy through a piezoelectric transducer. It can be used to generate energy for sensors in, for example, planes, vehicles, or vibrating industrial equipment.

For the new harvester, an experimental output power of 60µW was measured with an input acceleration of 2g at a resonance frequency of 500Hz. It consists of a piezoelectric capacitor formed by a Pt electrode, an AlN piezoelectric layer and a top Al electrode. The capacitor is fabricated on a cantilever which has a mass on its tip. When the harvester vibrates, the mass on the cantilever causes the piezoelectric layer to be stretched, inducing an electrical power. The use of AlN as piezoelectric material makes the device compatible with CMOS processes, allowing production at a lower cost.

Last year, IMEC already showcased a piezoelectric harvester with a reported 40µW output power. But this device had a piezoelectric layer fabricated with PZT. The current AlN layer has the advantage that it can be made in a simpler deposition process. Moreover, the PZT device operated at 1.8kHz. The lower resonance frequency of the new harvester - 500 Hz - corresponds with vibration frequencies in, for example, industrial equipment or car tires. This greatly enlarges the field of application for this harvester.

####

About IMEC

IMEC is a world-leading independent research center in nanoelectronics and nanotechnology. IMEC vzw is headquartered in Leuven, Belgium, has a sister company in the Netherlands, IMEC-NL, offices in the US, China and Taiwan, and representatives in Japan. Its staff of more than 1600 people includes more than 500 industrial residents and guest researchers. In 2007, its revenue (P&L) was EUR 244.5 million.

IMEC’s More Moore research aims at semiconductor scaling towards sub-32nm nodes. With its More than Moore research, IMEC looks into technologies for nomadic embedded systems, wireless autonomous transducer solutions, biomedical electronics, photovoltaics, organic electronics and GaN power electronics.

IMEC’s research bridges the gap between fundamental research at universities and technology development in industry. Its unique balance of processing and system know-how, intellectual property portfolio, state-of-the-art infrastructure and its strong network worldwide position IMEC as a key partner for shaping technologies for future systems.

About Holst Centre

Holst Centre is an independent open-innovation R&D centre that develops generic technologies for Wireless Autonomous Transducer Solutions and for Systems-in-Foil. A key feature of Holst Centre is its partnership model with industry and academia around shared roadmaps and programs. It is this kind of cross-fertilization that enables Holst Centre to tune its scientific strategy to industrial needs.

Holst Centre was set up in 2005 by IMEC (Flanders, Belgium) and TNO (The Netherlands) with support from the Dutch Ministry of Economic Affairs and the Government of Flanders. It is named after Gilles Holst, a Dutch pioneer in Research and Development and first director of Philips Research.

Located on the High Tech Campus in Eindhoven, Holst Centre benefits from the state-of-the-art on-site facilities. Holst Centre has over 100 employees (growing to over 200 by 2010) and a commitment from over 15 industrial partners.

Visit us at www.holstcentre.com

For more information, please click here

Contacts:

IMEC

Katrien Marent

Corporate Communications Director

Tel +32 16 28 18 80

Mobile: +32 474 30 28 66

Holst Centre

Koen Snoeckx

Communication Manager

Tel +31 40 277 40 91

Mobile: +31 612 71 98 43

Copyright © IMEC

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Energy

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

Battery Technology/Capacitors/Generators/Piezoelectrics/Thermoelectrics/Energy storage

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||